The 60 tons gantry crane is a professional heavy-duty material handling solution engineered to meet the rigorous demands of high-capacity lifting in industrial, port, and construction environments.

The 60 tons gantry crane is a professional heavy-duty material handling solution engineered to meet the rigorous demands of high-capacity lifting in industrial, port, and construction environments. Designed for reliability, efficiency, and safety, this crane delivers consistent performance when moving loads up to 60 metric tons, making it a cornerstone asset for businesses requiring robust lifting capabilities.

1. Robust & Durable Construction

Crafted with high-strength low-alloy steel or quenched and tempered steel, the 60 tons gantry crane boasts a sturdy framework that balances load-bearing capacity with structural lightness. Its main beam adopts a box-section or truss design for optimal weight distribution, while thick-walled steel legs—reinforced at critical stress points—ensure stability under full 60-ton loads. All welds undergo non-destructive testing (NDT) to eliminate structural flaws, and the entire structure is coated with anti-corrosive layers (shot blasting, primer, topcoat) to resist rust, moisture, and harsh outdoor conditions. A low center of gravity further enhances stability during lifting and movement, preventing tip-overs even in windy environments.

2. Precision Lifting & Movement Systems

At the core of the 60 tons gantry crane is a high-performance lifting mechanism, featuring a high-torque electric motor, heavy-duty reducer, and galvanized stainless-steel wire rope. This system lifts and lowers 60-ton loads smoothly, with adjustable speeds (0.5–5 m/min) to suit precise positioning or fast material transfer. The integrated load limiter acts as a safety guard, automatically cutting power if the load exceeds 110% of the rated 60 tons to avoid overloading accidents.

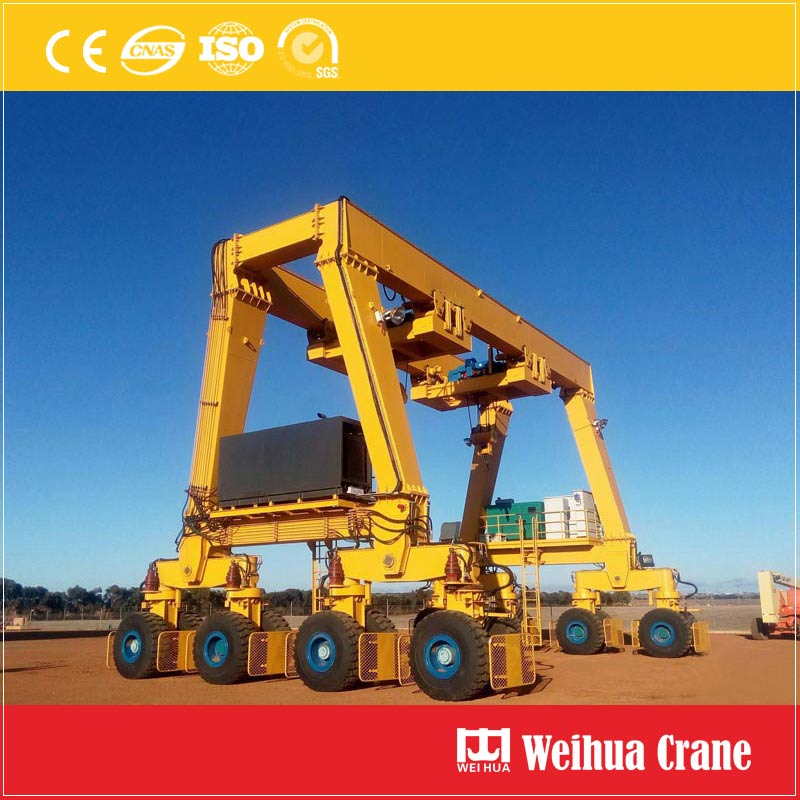

For horizontal movement, the 60 tons gantry crane offers two versatile options: rail-mounted (ideal for fixed workstations like factories or ports) for precise positioning, or tire-mounted (perfect for construction sites or uneven terrain) for flexible mobility. Independent motors and synchronization controls ensure smooth longitudinal and transverse movement, while electromagnetic disc brakes guarantee reliable stopping—even when carrying full 60-ton loads.

3. Advanced Control & Safety Features

Equipped with a PLC control system and user-friendly HMI, the 60 tons gantry crane enables intuitive operation in manual or semi-automatic modes, allowing operators to position loads with pinpoint accuracy. Optional slewing mechanisms expand the crane’s operating coverage, while standard safety features include emergency stop buttons, anti-collision sensors, and audible/visual alarms to mitigate risks. Weather-resistant add-ons (rain shields, low-light lighting) ensure the 60 tons gantry crane operates efficiently in all outdoor conditions, from scorching heat to heavy rain.

| Parameter | Details |

| Rated Load Capacity | 60 metric tons (safety factor: 3–5x rated capacity) |

| Span Range | 10–30+ meters (customizable for specific workspaces) |

| Lifting Height | 8–20 meters (extendable for tall facilities) |

| Lifting Speed | 0.5–5 m/min (variable frequency drive for smooth adjustment) |

| Trolley Travel Speed | 5–20 m/min |

| Crane Travel Speed | 10–30 m/min (rail-mounted); slightly lower for tire-mounted models |

| Power Supply | 380V/400V, 50Hz/60Hz (customizable for regional standards) |

| Control Mode | PLC + HMI (manual/semi-automatic) |

Ports & Terminals

The 60 tons gantry crane is a workhorse for port operations, efficiently loading and unloading 20/40-foot shipping containers (30–40 tons each) and bulk materials (coal, ore, grain) from ships to trucks or storage yards. Its rail-mounted design operates along dock lengths, processing high cargo volumes to reduce ship turnaround times and boost logistics efficiency.

Construction Sites

On construction projects, the 60 tons gantry crane handles heavy structural components—precast concrete beams, steel columns, reinforcement cages—and large machinery (excavators, generators). Tire-mounted models navigate unpaved terrain with ease, lifting materials to upper floors of high-rise buildings and streamlining construction timelines while minimizing manual labor risks.

Factories & Warehouses

In manufacturing plants (steel mills, automotive facilities, heavy machinery factories), the 60 tons gantry crane transports oversized raw materials (steel coils, aluminum ingots) to production lines and moves finished products to storage. In warehouses, it maximizes vertical storage space by stacking heavy goods, integrating with production workflows to enhance operational efficiency and reduce downtime.

To preserve the performance of your 60 tons gantry crane:

Safety protocols: Operators must be certified; never overload the crane; secure loads properly; avoid sudden movements; and cease operation in extreme weather (strong winds, lightning) unless equipped with specialized safety features.

Our 60 tons gantry crane is engineered to meet international quality standards, with customizable configurations to match your specific operational needs. From port logistics to construction and manufacturing, this crane delivers the power, precision, and reliability required to handle heavy-duty lifting challenges—helping you boost productivity, reduce costs, and ensure a safe working environment.

For custom specifications, pricing, or technical support, contact our team today to find the perfect 60 tons gantry crane solution for your business.

Share with PDF: Download

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.

A grab bucket overhead crane is a specialized material handling machine designed to str……

Discover More →

Overhead crane wheels are responsible for bearing the full load of the crane and the lif……

Discover More →

As a professional heavy-duty lifting equipment, the double trolley overhead crane (also……

Discover More →

Latest Comments