Cranes are the workhorses of modern industry, essential for lifting, moving, and positioning heavy loads with precision and efficiency. From manufacturing floors to bustling ports and massive construction sites, different types of cranes are designed for specific tasks and environments. Understanding these variations is key to selecting the right equipment for the job. This guide explores the main types of industrial and logistical cranes, their unique features, and their primary applications.

Overhead cranes are ubiquitous in factories, warehouses, and workshops. They consist of a hoist that moves along a horizontal beam (the bridge), which itself moves on elevated runways along the building’s length.

Single Girder Overhead Crane

Double Girder Overhead Crane

Gantry cranes are similar to overhead cranes but are supported by freestanding legs that move on wheels or rails along the ground, eliminating the need for a building’s roof structure. They are highly versatile for both indoor and outdoor use.

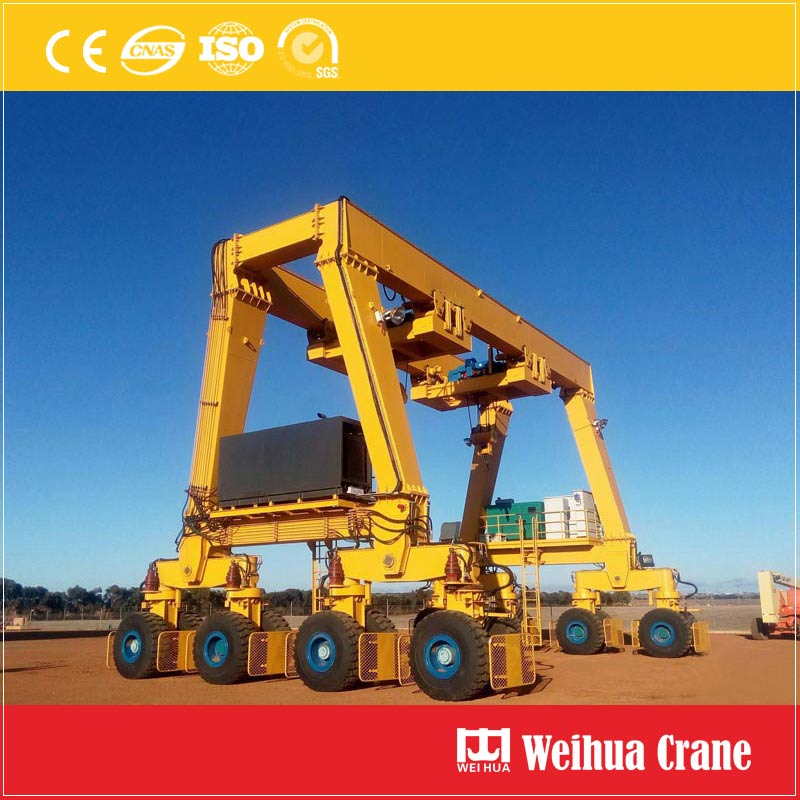

Rubber-Tired Gantry (RTG) Crane

Rubber-Tired Gantry (RTG) Crane: A mobile gantry crane used primarily in container terminals. It runs on rubber tires, making it highly flexible for stacking containers in yard operations.

Rail-Mounted Gantry (RMG) Crane

Rail-Mounted Gantry (RMG) Crane: Similar to an RTG but runs on fixed rail tracks. This allows for more precise positioning, higher stacking capabilities, and is better suited for automated operations.

These are heavy-duty giants designed specifically for the rapid loading and unloading of ships.

Ship-to-Shore (STS) Crane

Ship-to-Shore (STS) Crane / Container Gantry Crane: These are the iconic, colossal cranes seen at container terminals. They straddle a ship at berth, moving containers directly between the vessel and the quay. They are essential for modern containerized shipping.

Container Gantry Crane

Mobile Harbor Crane: A versatile, wheeled or rail-mounted crane that can perform multiple tasks, including handling containers, bulk materials, and general cargo. It offers great flexibility for multi-purpose ports.

Often referred to as “Goliath” cranes, these are heavy-duty, large-capacity gantry cranes used for massive lifts.

Q1: What is the most common type of crane inside a factory?

A: The Overhead Bridge Crane is the most common, with single girder cranes for lighter work and double girder cranes for heavy manufacturing.

Q2: What’s the main difference between an RTG and an RMG?

A: RTGs (Rubber-Tired Gantry) are mobile and flexible, moving freely in a yard. RMGs (Rail-Mounted Gantry) run on fixed tracks, offering greater precision, stability for higher stacking, and are easier to automate.

Q3: Which crane is specifically designed for unloading container ships?

A: The Ship-to-Shore (STS) Container Gantry Crane is specifically engineered for this high-speed, high-capacity task.

Q4: What type of crane would be used to build a large ship?

A: Massive Portal/Gantry Cranes (often called Goliath or shipbuilding gantries) are used to lift and position large prefabricated sections of a ship’s hull and superstructure.

Q5: How do I choose the right type of crane?

A: Key factors include: Weight and size of loads, required span and lifting height, duty cycle (frequency of use), available space (indoor/outdoor), mobility needs, and budget. Consulting with a crane specialist is always recommended.

From the precision of a workshop’s overhead crane to the raw power of a port’s STS crane, each type of crane plays a vital role in global industry and infrastructure. Selecting the correct crane—whether it’s a versatile gantry, a specialized container handler, or a heavy-lift portal crane—is fundamental to achieving safety, efficiency, and productivity in any material handling operation.

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.

Latest Comments