A single girder overhead crane is a versatile material handling equipment designed for lifting and moving loads in industrial settings.

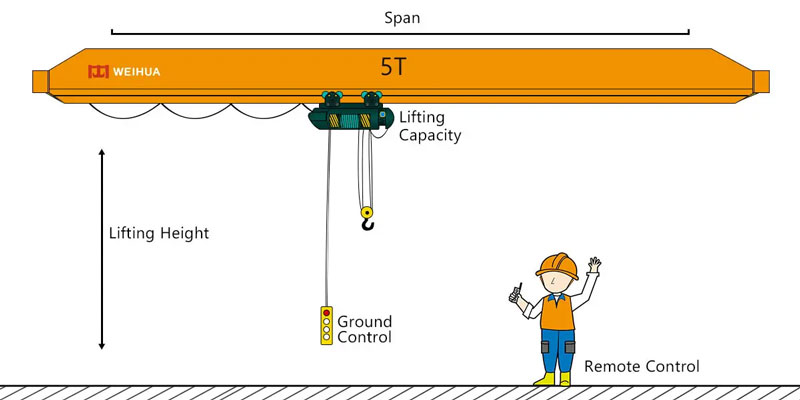

A single girder overhead crane is a versatile material handling equipment designed for lifting and moving loads in industrial settings. Composed of a single main beam (poutre) supported by end carriages, a trolley, and a hoist, this crane operates on elevated runways, maximizing floor space utilization. Ideal for light to medium-duty applications, it balances cost-effectiveness, compact design, and reliable performance—making it a go-to choice for factories, entrepôts, and workshops seeking efficient load management.

Our single girder overhead cranes are engineered to meet rigorous industrial demands, with features that set them apart:

|

Paramètre

|

Range/Details

|

|

Capacité de levage

|

0.5 - 32 tonnes (customizable for higher capacities upon request)

|

|

Longueur de portée

|

5 - 30 mètres (adjustable based on facility dimensions)

|

|

Hauteur de levage

|

3 - 30 mètres (extendable with specialized configurations)

|

|

Classe ouvrière

|

A3-A5 (suitable for medium-duty, intermittent operations)

|

|

Vitesse de levage

|

0.8 - 16 m / mon (options de vitesse variable disponibles)

|

|

Vitesse de déplacement du chariot

|

10 - 30 m / mon

|

|

Vitesse de déplacement de la grue

|

20 - 45 m / mon

|

|

Alimentation électrique

|

380V/3PH/50Hz (customizable for 220V, 440V, or other regional standards)

|

|

Système de contrôle

|

Commande suspendue, télécommande (wireless optional), or PLC integration

|

Our single girder overhead cranes excel in diverse sectors, streamlining material handling across:

Q1: What’s the difference between a single girder and pont roulant bipoutre?

A1: Single girder cranes use one main beam, sont plus légers, more affordable, and ideal for light to medium loads. Double girder overhead cranes have two beams, offering higher lifting capacities (32+ tonnes) and greater stability for heavy-duty applications.

Q2: Can a single girder overhead crane be installed outdoors?

A2: Yes—we offer weatherproof models with corrosion-resistant coatings, sealed electrical components, and rain shields, suitable for outdoor yards or construction sites.

Q3: How long does installation take?

A3: Installation typically takes 3–7 days, depending on the crane size, site preparation (Par exemple, runway setup), and configuration complexity. Our team provides on-site support for seamless setup.

T4: What maintenance is required?

A4: Regular maintenance includes checking hoist cables for wear, lubricating trolley/overhead crane wheels, testing safety switches, and inspecting electrical connections. We recommend quarterly inspections for optimal performance.

Q5: Are your cranes compliant with international standards?

A5: Absolument. All our single girder overhead cranes meet ISO 9001 quality standards, CE certification for EU markets, and OSHA guidelines for safety, ensuring global compatibility.

Partager avec PDF: Télécharger

Nous apprécions vos commentaires! Veuillez remplir le formulaire ci-dessous afin que nous puissions adapter nos services à vos besoins spécifiques.

UN 20 tonnes est un portique robuste, équipement de levage polyvalent conçu pour gérer des charges lourdes……

Découvrir plus →

Designed specifically for the rigorous demands of metal processing, automotive manufact……

Découvrir plus →

Cliquez sur le bouton pour obtenir des informations et des citations de produits sur WhatsApp.

Obtenez un devis

Dernières commentaires