Our Heavy-Duty Marine Crane Hook is precision-engineered for the rigorous demands of shipyard lifting operations. Built to handle massive loads, resist harsh marine environments, and ensure maximum safety, this hook is the critical link between your crane and cargo—from engine blocks and steel plates to ship sections and dry-dock equipment.

1. Uncompromising Strength & Durability

Material: Forged from high-tensile alloy steel (Grade 100/Alloy E), heat-treated for exceptional toughness.

Load Capacity: Rated for SWL (Safe Working Loads) from 5 to 500+ tons. Custom designs available.

Corrosion Resistance: Triple-protected with hot-dip galvanizing, marine-grade epoxy coating, or stainless steel variants (316L).

2. Enhanced Safety Systems

Safety Latch: Spring-loaded, manual, or semi-automatic latches prevent accidental disengagement.

Overload Protection: Optional integrated load cells for real-time monitoring (API-compliant).

Fail-Safe Design: Fatigue-resistant construction per FEM 9.511 and ISO 4301/EN 13889 standards.

3. Optimized for Marine Workflows

360° Rotation: Swivel hooks eliminate wire rope twisting during precise positioning.

Low-Profile Design: Clears confined shipboard spaces, decks, and dry-dock structures.

Shock Absorption: Resilient thrust bearings reduce dynamic stress during heavy lifts.

4. Smart Inspection & Maintenance

Wear Indicators: Visual markers highlight critical wear zones (throat, tip).

Easy-Grease Fittings: Lubrication ports extend bearing/bolt life.

Traceability: Laser-etched ID with SWL, serial number, and certification details.

| Parameter | Specification |

| Model Series | MCH-SY (Standard) / MCH-PLUS (Advanced) |

| Safe Working Load (SWL) | 5–500 tons |

| Design Safety Factor | ≥ 5:1 (per ISO 4301) |

| Material | Alloy Steel (Grade 100/Alloy E) |

| Forging Process | Closed-die forging, ultrasonic tested |

| Heat Treatment | Quenched & tempered (HRC 38-42) |

| Corrosion Protection | Triple-layer: Zn-phosphating + HDG + epoxy coating (250μm) |

| Rotation | 360° continuous rotation |

| Bearing Type | Tapered roller thrust bearing (grease-lubricated) |

| Safety Latch | Spring-loaded (standard), semi-automatic, or RFID-sensor enabled |

| Operating Temp. | -40°C to +150°C |

| Fatigue Life | 500,000 cycles @ 60% SWL (ISO 4301-5) |

| Wear Limit | Max 10% throat reduction / 5% hook tip deformation (ASME B30.10) |

| NDT Requirements | MPI every 6 months; UT for hooks >100 tons |

| Certifications | DNV-GL, ABS, Lloyd’s Register, CCS, IRS |

| Dimensions (Example) | *MCH-SY 100-ton:* – Throat: 320 mm – Width: 180 mm – Height: 785 mm |

Tailored Solutions for Complex Lifts:

| Requirement | Our Capability |

| Extreme Environments | Arctic-grade hooks (-60°C), explosive atmosphere (ATEX) variants |

| Non-Standard Loads | Asymmetric hooks for angled lifts, ergonomic grips for delicate components |

| Automation Ready | Robotic interface pads, auto-latching sensors, remote load telemetry |

| Retrofit Kits | Legacy crane upgrades with digital load cells + anti-collision systems |

| Feature | Technical Value | Compatibility |

| Integrated Load Cell | ±0.5% accuracy, 4-20mA/RS485 output | API 9B/ISO 17025 certified |

| Anti-Sway System | Active gyro damping (response time: <0.8 sec) | Crane PLC integration ready |

| RFID Monitoring | ISO 18000-6C tags (memory: 8 KB) | Synced with EAM/CMMS |

| ATEX Certification | Zone 1/21 (IIB+H2 T85°C) | Explosion-proof latches |

| Quick-Change Adapter | DIN 15403-compliant interface | For grabs, shackles, or magnets |

1. Hook Blocks & Assemblies

Tandem Hooks: Multi-hook spreader beams for balanced lifting of irregular loads (e.g., ship modules).

Rotating Sheaves: Integrated pulley systems reduce wire abrasion + enable vertical reeving (ISO 4309 compliant).

Anti-Sway Technology: Gyro-stabilized hooks with inertial dampeners for precision placement in windy docks.

2. Smart Attachments

RFID Tagging: Wireless load tracking + automated inspection logs (compatible with IoT crane platforms).

Vision-Assist Kits: Embedded cameras + LiDAR for blind-spot monitoring during confined space lifts.

Quick-Change Adapters: Interchangeable hook heads (clevis, grab, shackle) for rapid task switching.

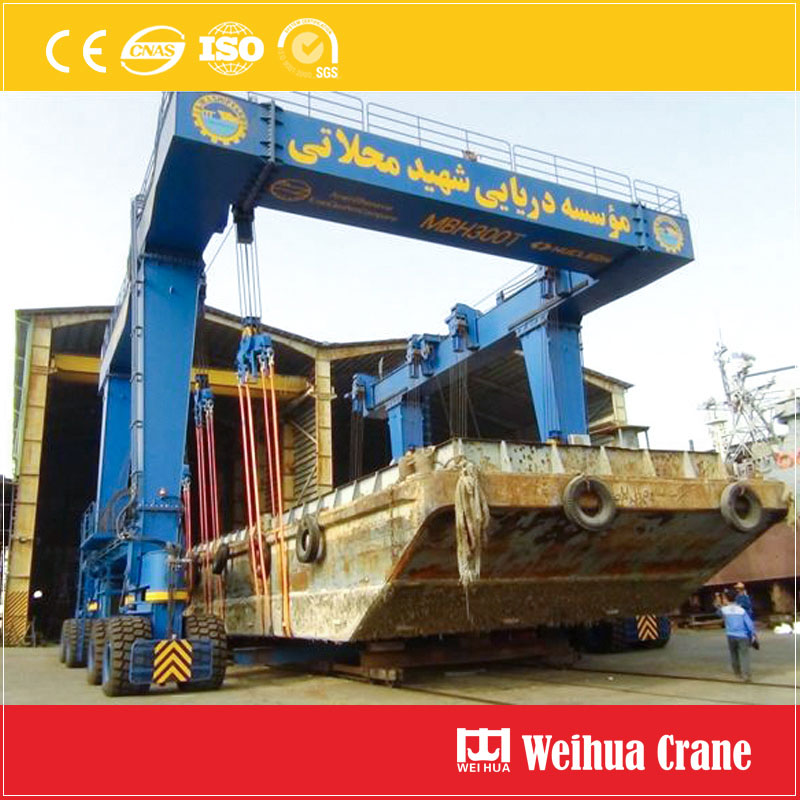

1. Dry-Dock Lifting: Hull sections, propellers, rudders.

2. Fabrication Shops: Steel plates, pipe racks, machinery.

3. Outfitting Quays: Engine installations, modular cabins.

4. Heavy Transport: Gantry crane operations, load-outs.

Zero-Failure Legacy: 200,000+ hours operational reliability in global shipyards.

Custom Engineering: Tailored shank lengths, latches, or RFID tags for digital fleet management.

Global Compliance: Certified for EU, US, and Asian maritime safety regimes.

Request a Quote or Technical Dossier

Upgrade your lifting safety with hooks built to withstand salt, storm, and strain. Contact our engineering team for load diagrams, CAD models, and rapid prototyping.

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.

Latest Comments