Crane hook vs. shackle lifting capacity

2025-09-18

In the world of lifting and rigging, safety is paramount. Two of the most fundamental components in any lift are the crane hook and the shackle. It’s common to hear questions on the job site like, “Which one is stronger?” or “Can I lift a 20-ton load if my hook is rated for 20 tons?”

This line of thinking is dangerous. You cannot directly compare the lifting capacity of a crane hook to a shackle because they serve different functions and are rated under different conditions.

Understanding this distinction is not just technical jargon—it’s the bedrock of safe lifting operations. Let’s break down the critical differences.

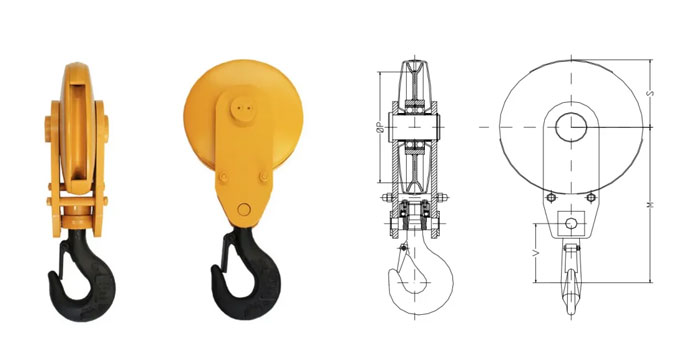

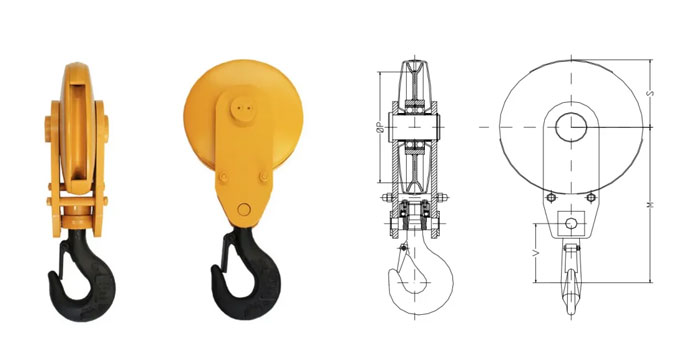

The Crane Hook: The Machine’s Interface

The crane hook is the terminating end of the hoist or crane. Its capacity is not a standalone number.

- 1. It’s a System Rating: The rated capacity of a crane hook is intrinsically tied to the crane or hoist it is attached to. A 20 ton crane hook on a 20-ton crane means the entire system—the wire rope, the boom, the hydraulics, and the hook—is designed to handle a 20-ton load.

- 2. The “Rated Capacity” Marking: The capacity stamped on the hook (e.g., “20T”) refers to the maximum load that the entire crane system can safely lift when the load is perfectly centered in the bowl of the hook. This rating assumes ideal, straight-line vertical lifting.

- 3. The Weakest Link: The hook is often one of the strongest points in the system, but its rated capacity is limited by the machine it’s on. Using a 50 ton crane hook on a 20-ton crane doesn’t magically increase the crane’s capacity; the crane itself remains the limiting factor.

The Shackle: The Connection Point

Shackles are primarily used to connect various rigging elements, like slings, to the load or to the crane hook.

- 1. A Standalone Component: A shackle has its own independent Working Load Limit (WLL). This is the maximum load it can safely handle in a straight-line pull.

- 2. Angle is Everything: Unlike a crane hook which is designed for a centered load, a shackle’s capacity is drastically affected by how it is used. When slings are choked or used in a basket hitch, the tension on the shackle increases exponentially. A qualified rigger must calculate these angles and derate the shackle accordingly.

- 3. Pin Positioning is Critical: The shackle’s WLL is only valid when the load is applied on the crown (the rounded bow) and not on the pin. Loading the pin side can reduce the shackle’s capacity by 50% or more, a common and catastrophic mistake.

The Crucial Interaction: How They Work Together

The real question isn’t “Which is stronger?” but “Are my components compatible and correctly used?”

Here’s the golden rule: The weakest rated component in the entire lifting system dictates the maximum safe working load.

Your lifting system is a chain: Crane Capacity → Sling WLL → Shackle WLL → Load.

Example Scenario:

- Your crane has a capacity of 20 tons (with its hook).

- You have a shackle with a WLL of 15 tons.

- You have slings with a WLL of 20 tons.

What is your maximum safe lift?

Answer: 15 tons. The shackle is the weakest link. Exceeding its WLL to utilize the full crane capacity risks breaking the shackle and dropping the load.

Best Practices for Safe Lifting

- 1. Know the Ratings: Never assume. Look for the stamped WLL or rated capacity on every piece of equipment—the crane, the hook, the shackles, and the slings.

- 2. Inspect Everything: Conduct pre-use inspections. Look for cracks, deformation, wear, and damaged threads on shackle pins. Any doubt, take it out of service.

- 3. Understand the Load: Consider the weight of the load, the center of gravity, and the rigging angles. Use sling angle calculations to determine the actual tension on your shackles.

- 4. Match Components: Ensure all rigging hardware (shackles, slings) is rated for the load and compatible with the crane’s capacity. Never use a shackle whose WLL is lower than the crane’s capacity unless the load itself is lighter.

- 5. Center the Load: Always ensure the load is seated in the base (bowl) of the crane hook. Never “point load” the tip of the hook.

Pitting crane hook capacity against shackle capacity is a flawed comparison. They are not competitors; they are teammates in a larger system. The crane hook represents the machine’s capability, while the shackle represents a critical link in the connection chain.

True safety and professionalism come from understanding that the entire lift is only as strong as its weakest component. Always plan your lift, know your ratings, and never exceed the lowest WLL in your rigging setup. Your life, and the lives of your crew, depend on it.

Latest Comments