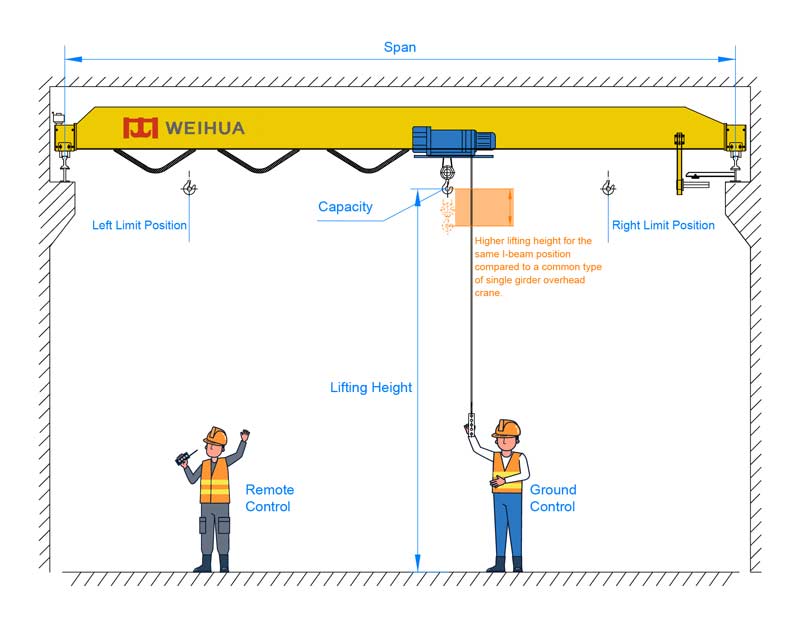

The low headroom overhead crane is a specialized material handling equipment designed to operate efficiently in spaces with limited vertical clearance.

|

Parameter

|

Specification

|

|---|---|

|

Lifting Capacity

|

1t – 50t

|

|

Span

|

5m – 30m

|

|

Lifting Height

|

3m – 20m (adjustable according to headroom)

|

|

Lifting Speed

|

0.5m/min – 10m/min (stepless speed regulation)

|

|

Trolley Travel Speed

|

5m/min – 30m/min

|

|

Crane Travel Speed

|

10m/min – 60m/min

|

|

Power Supply

|

380V/50Hz/3Ph (customizable for different regions)

|

|

Control Mode

|

Pendent control, wireless remote control, cabin control

|

The low headroom overhead crane is widely used in industries where vertical space is limited. Its main application fields include:

Q: What is the minimum headroom required for a low headroom overhead crane?

A: The minimum headroom depends on the specific model and lifting capacity. Generally, it can be as low as 1.5m – 2.5m. We will provide a detailed headroom calculation based on your actual working conditions and requirements.

Q: Can the low headroom overhead crane be used outdoors?

A: Yes, but it needs to be equipped with weatherproofing measures, such as rain covers, anti-corrosion coatings, and waterproof electrical components, to adapt to outdoor environments. We can provide outdoor-specific configurations according to your needs.

Q: How often does the crane need to be maintained?

A: Routine maintenance should be carried out monthly, including checking the hoisting mechanism, brakes, electrical system, and safety devices. Annual comprehensive maintenance is also required to ensure the crane operates in good condition. We can provide a maintenance manual and professional maintenance services.

Q: What is the service life of the low headroom overhead crane?

A: Under normal use and proper maintenance, the service life is usually 10 – 15 years. The service life can be extended by regular maintenance and timely replacement of worn parts.

Q: Can the crane be upgraded or modified after installation?

A: Yes, we can provide upgrade and modification services, such as increasing the lifting capacity, extending the span, adding anti-sway devices, or upgrading the control system. However, the modification needs to be designed and implemented by professional technicians to ensure safety and performance.

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.

Aluminium smelter operations are characterized by harsh working environments, high-temp……

Discover More →

In the realm of heavy-duty material handling, the double trolley gantry crane stands ou……

Discover More →

20 Ton Single Girder vs. Double Girder Bridge Cranes The primary distinction in 20-ton o……

Discover More →

Latest Comments