The 100 tons gantry crane is a high-performance, heavy-duty lifting equipment designed for handling large and heavy loads in various industrial and logistics scenarios. Adopting advanced double-girder structure design, it combines excellent stability, strong load-bearing capacity and reliable operation, making it an indispensable core equipment in heavy industry production, port terminals, and large-scale construction projects. With strict quality control and sophisticated manufacturing processes, this gantry crane meets international safety standards and can adapt to harsh working environments, providing efficient and safe lifting solutions for customers.

100 Tons Gantry Crane Technical Parameters

|

Parameter Item

|

Specification

|

|

Rated Lifting Capacity

|

100 Tons

|

|

Span (S)

|

20m – 50m (Customizable)

|

|

Lifting Height (H)

|

12m – 30m (Customizable)

|

|

Lifting Speed

|

0.5m/min – 5m/min (Variable Frequency Speed Regulation)

|

|

Trolley Travel Speed

|

5m/min – 20m/min (Variable Frequency Speed Regulation)

|

|

Crane Travel Speed

|

10m/min – 30m/min (Variable Frequency Speed Regulation)

|

|

Working Class

|

A5 – A7

|

|

Power Supply

|

380V/50Hz/3Ph (Customizable According to Regional Standards)

|

|

Overall Weight

|

Depends on Span and Lifting Height (Approx. 80T – 150T)

|

|

Operating Temperature

|

-20℃ – +40℃

|

100 Tons Gantry Crane Structural Features

- 1. Robust Double-Girder Structure: The main beam adopts a box-type double-girder structure, which is formed by high-quality low-alloy high-strength steel plate through precise welding and strict flaw detection. This structure effectively improves the overall rigidity and load-bearing capacity of the crane, ensuring stable operation even when lifting the maximum load of 100 tons, and reducing the deformation of the main beam during operation.

- 2. Optimized End Carriage Design: The end carriage is designed with a rigid connection structure, and the walking mechanism adopts high-precision gearboxes and heavy-duty wheels. The wheels are made of wear-resistant alloy steel, which has good wear resistance and impact resistance. The walking system is equipped with frequency conversion speed regulation function, which can realize smooth start, stop and speed adjustment, reducing the impact on the crane structure and the ground track.

- 3. Advanced Lifting Mechanism: The lifting mechanism is composed of a high-power motor, a high-efficiency reducer and a reliable brake. The wire rope is made of high-strength galvanized steel wire, which has strong tensile strength and corrosion resistance. The lifting hook is forged from alloy steel, after heat treatment to improve its hardness and toughness, ensuring safe lifting of heavy loads. At the same time, the lifting mechanism is equipped with overload protection, overheating protection and other safety devices to prevent accidents.

- 4. Compact Electrical Control System: The electrical control system adopts imported brand components, with stable performance and high reliability. It is equipped with a PLC control system, which can realize automatic control and remote operation of the crane. The operation console is designed ergonomically, with clear buttons and easy operation, reducing the labor intensity of operators.

- 5. Excellent Anti-Corrosion and Durability: The entire crane surface is treated with shot blasting and anti-corrosion painting, which can effectively resist rust and corrosion in harsh environments such as humidity, dust and salt spray. The key components are subjected to strict anti-wear treatment, extending the service life of the crane.

100 Tons Gantry Crane Application Scenarios

- 1. Heavy Machinery Manufacturing: Used for lifting and assembling large mechanical parts such as engine blocks, machine tool beds, and hydraulic presses in heavy machinery factories. The 100-ton lifting capacity can easily handle large workpieces, improving the efficiency and accuracy of assembly operations.

- 2. Port and Terminal Logistics: Applied to the loading and unloading of large cargo such as containers, steel coils, and bulk materials at ports and terminals. The large span and long lifting height design make it suitable for large-scale storage yards and wharves, realizing efficient transfer of goods between ships, trucks and warehouses.

- 3. Steel Mills and Metallurgical Industry: Used in steel mills for lifting steel ingots, steel plates, steel coils and other products during the smelting and rolling process. It can adapt to the high-temperature, dusty working environment in steel mills, and the anti-corrosion and high-temperature resistance design ensures stable operation.

- 4. Wind Power Equipment Installation and Maintenance: Used for lifting and installing large wind power components such as wind turbine nacelles, hubs and blades in wind power plants. The high stability and precise control performance can ensure the safe and smooth installation of wind power equipment in high-altitude and outdoor environments.

- 5. Large-Scale Construction Projects: Applied to the construction of large-scale projects such as bridges, tunnels and high-rise buildings, used for lifting large construction materials such as steel bars, concrete components and bridge girders. It can adapt to the complex construction site environment and provide strong support for the progress of the project.

- 6. Mining and Metallurgy: Used in mines and metallurgical mines for lifting ore, coal and other bulk materials, as well as large mining equipment maintenance and handling. The strong load-bearing capacity and reliable performance can meet the harsh working conditions in mines.

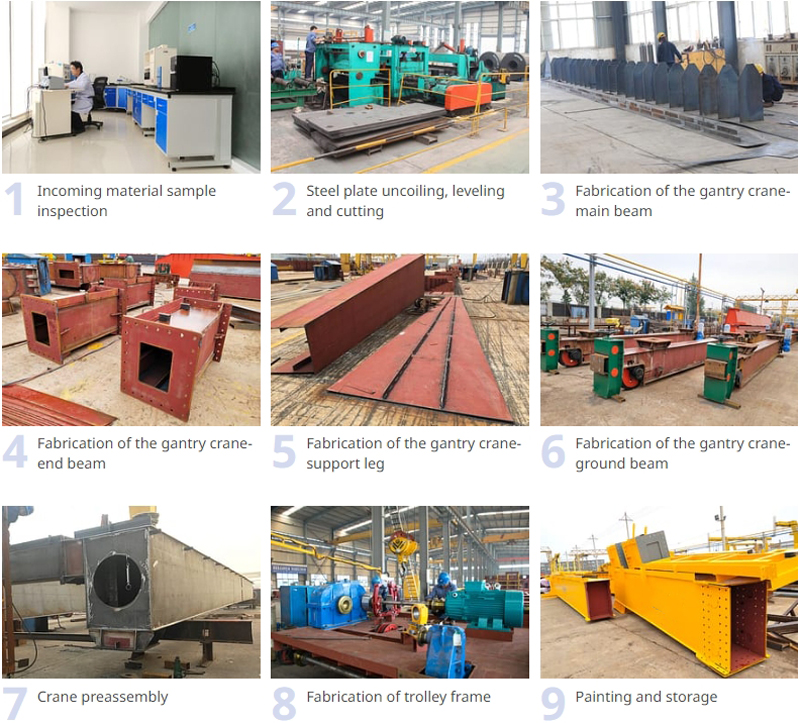

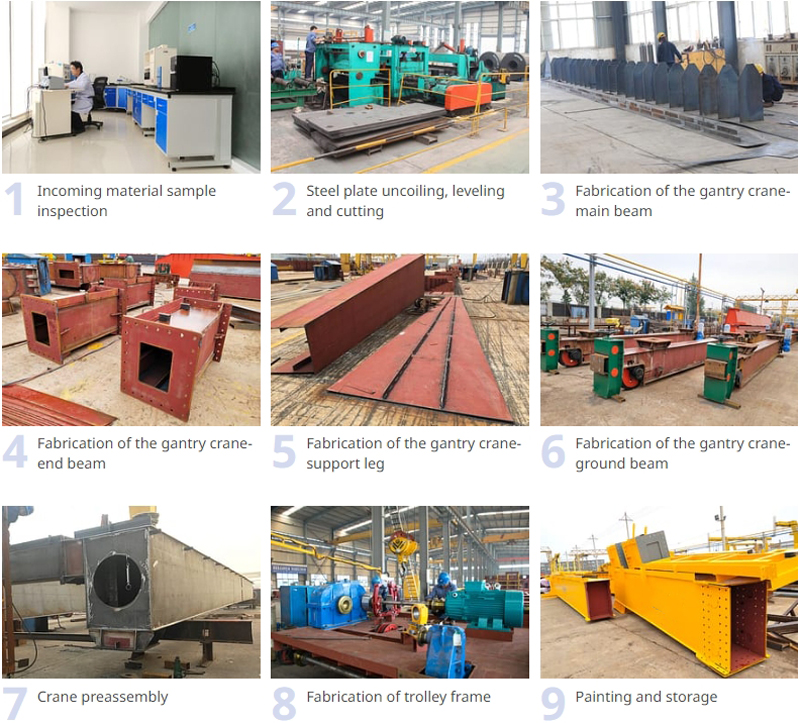

100 Tons Gantry Crane Manufacturing Process

Product Advantages

The 100 tons double girder gantry crane has the advantages of high load-bearing capacity, stable operation, safe and reliable, easy operation and maintenance. It adopts advanced design concepts and manufacturing processes to ensure the quality and performance of the product. At the same time, we can provide customized solutions according to the specific needs of customers, including span, lifting height, working class and other parameters, to meet the diverse needs of different industries. In addition, we provide perfect after-sales service, including installation and commissioning, technical training, maintenance and repair, to ensure that customers can use the product with confidence.

Share with PDF: Download

Latest Comments