A single girder overhead crane is a versatile material handling equipment designed for lifting and moving loads in industrial settings.

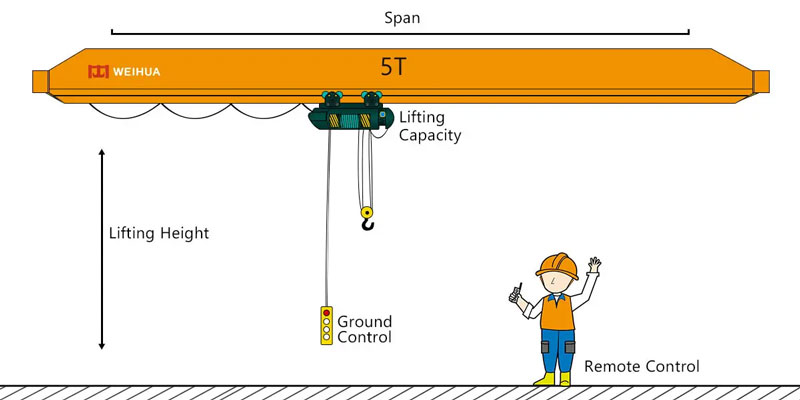

A single girder overhead crane is a versatile material handling equipment designed for lifting and moving loads in industrial settings. Composed of a single main beam (balk) supported by end carriages, a trolley, and a hoist, this crane operates on elevated runways, maximizing floor space utilization. Ideal for light to medium-duty applications, it balances cost-effectiveness, compact design, and reliable performance—making it a go-to choice for factories, pakhuizen, and workshops seeking efficient load management.

Our single girder overhead cranes are engineered to meet rigorous industrial demands, with features that set them apart:

|

Parameter

|

Bereik/details

|

|

Hefcapaciteit

|

0.5 – 32 ton (customizable for higher capacities upon request)

|

|

Overspanningslengte

|

5 – 30 meter (adjustable based on facility dimensions)

|

|

Hefthoogte

|

3 – 30 meter (extendable with specialized configurations)

|

|

Werkklasse

|

A3 – A5 (suitable for medium-duty, intermittent operations)

|

|

Hoist Speed

|

0.8 – 16 m/mijn (variable speed options available)

|

|

Reissnelheid van de trolley

|

10 – 30 m/mijn

|

|

Kraansnelheid

|

20 – 45 m/mijn

|

|

Stroomvoorziening

|

380V/3PH/50Hz (customizable for 220V, 440V, or other regional standards)

|

|

Besturingssysteem

|

Hangerbediening, afstandsbediening (wireless optional), or PLC integration

|

Our single girder overhead cranes excel in diverse sectors, streamlining material handling across:

Q1: What’s the difference between a single girder and dubbelligger bovenloopkraan?

A1: Single girder cranes use one main beam, are lighter, more affordable, and ideal for light to medium loads. Double girder overhead cranes have two beams, offering higher lifting capacities (32+ ton) and greater stability for heavy-duty applications.

Q2: Can a single girder overhead crane be installed outdoors?

A2: Yes—we offer weatherproof models with corrosion-resistant coatings, sealed electrical components, and rain shields, suitable for outdoor yards or construction sites.

Q3: How long does installation take?

A3: Installation typically takes 3–7 days, depending on the crane size, site preparation (Bijv., runway setup), and configuration complexity. Our team provides on-site support for seamless setup.

Q4: Welk onderhoud is er nodig?

A4: Regular maintenance includes checking hoist cables for wear, lubricating trolley/overhead crane wheels, testing safety switches, and inspecting electrical connections. We recommend quarterly inspections for optimal performance.

Vraag 5: Are your cranes compliant with international standards?

A5: Absoluut. All our single girder overhead cranes meet ISO 9001 quality standards, CE certification for EU markets, and OSHA guidelines for safety, ensuring global compatibility.

Deel met PDF: Downloaden

Wij waarderen uw feedback! Vul het onderstaande formulier in, zodat we onze services kunnen aanpassen aan uw specifieke behoeften.

Uitgerust met dubbele liggers, dit 25 ton dubbelligger portaalkraan zorgt voor grotere steek……

Ontdek meer →

The European style double girder overhead crane is a high-performance, energy-efficient……

Ontdek meer →

De 100 tons overhead crane is a professional heavy-duty lifting equipment designed for……

Ontdek meer →

Klik op de knop om productinformatie en offertes op WhatsApp te krijgen.

Krijg citaat

Laatste opmerkingen