Dans le monde exigeant de la manutention, où la sécurité et la fiabilité sont primordiales sous des charges extrêmes, Les crochets de levage robustes Weihua constituent la pierre angulaire d'opérations sécurisées et efficaces.. Conçu pour relever les défis les plus difficiles en matière de construction, fabrication, construction navale, exploitation minière, et logistique portuaire, Les crochets Weihua offrent des performances inégalées là où l'échec n'est pas une option.

Groupe Weihua, un leader mondialement reconnu dans les solutions de levage et de levage, apporte des décennies d'expertise en ingénierie spécialisée à chaque crochet de levage robuste qu'ils fabriquent. Choisir Weihua, c'est investir dans:

| Catégorie de paramètre | Caractéristiques | Remarques/Configurations facultatives |

| Spécifications de base | ||

| Limite de chargement de travail (Wll) | 1 tonne ~ 500 tonnes | Personnalisable (jusqu'à 1000+ tonnes) |

| Facteur de sécurité | ≥ 5:1 | Conforme aux normes FEM/ASME (jusqu'à 6:1) |

| Température de fonctionnement | -40°C à +200°C | Coutume: -196°C ou +450°C |

| Conception structurelle | ||

| Matériel | Acier forgé allié à haute résistance (35CRMO, 42CRMO, 34Cr2Ni2Mo) | Conforme au GB/T 3077, VOTRE UN 10083 |

| Processus de fabrication | Forgeage à die fermée + Usinage CNC | Le flux des grains suit le contour du crochet |

| Type de crochet | – Crochet simple (Chape/tige à œil) – Ramshorn (Double) Crochet - Crochets de grue pivotant |

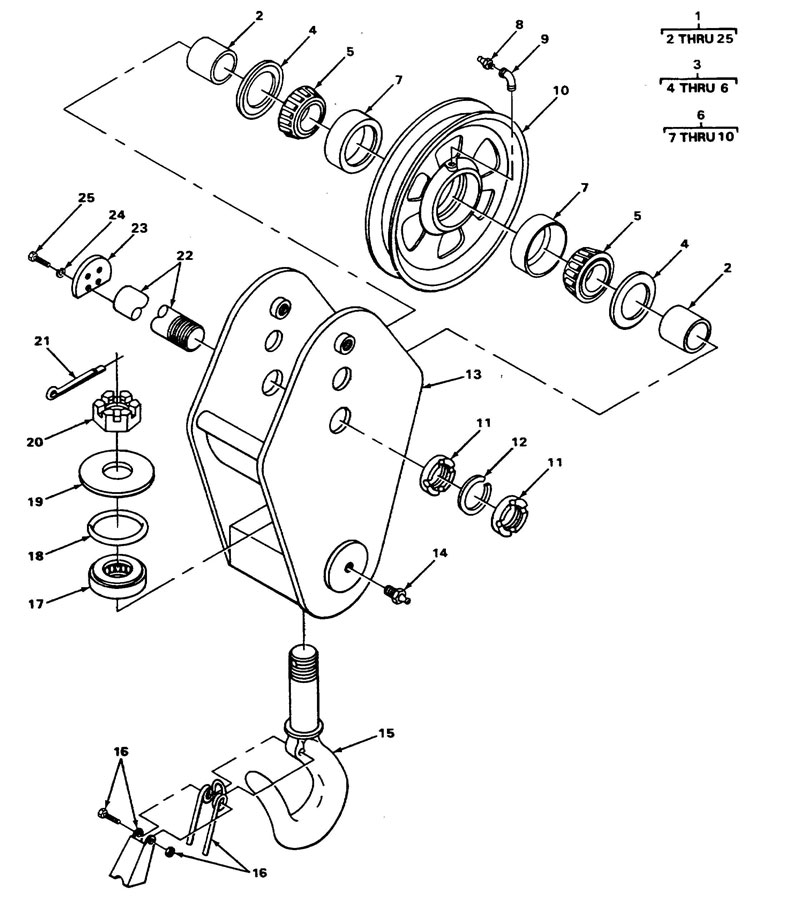

Type de roulement: Rouleau conique/à billes |

| Diamètre de la gorge (D) | 50mm ~ 1500 mm | Personnalisable par géométrie de charge |

| Caractéristiques de sécurité | ||

| Type de loquet de sécurité | – Loquet à ressort – Loquet à verrouillage positif – Sans verrouillage |

Force de verrouillage ≥ 10% Wll (mécanique) |

| Matériau du loquet | Acier en alliage + durcissement superficiel (HRC 40-45) | Conception résistante aux chocs |

| Traitement de surface | ||

| Anticorrosion standard | Électro-galvanisé (8-12μm) | Essai au brouillard salin > 96 heures |

| Protection améliorée | – Galvanisé à chaud (70-100μm) – Revêtement Xylan®/Dacromet |

Environnements marins/chimiques |

| Certifications | ||

| Normes de conception | ISO 9001, ASME B30.10, Femelle 9.511, DEPUIS 15401, GB / T 10051 | |

| 3Certification tierce | TUV, Dnv-gl, Registre de Lloyd, CE | Nucléaire (ASME QA-1), Exploitation minière (MSHA) |

| Méthodes de test | - 100% MPI – Tests par ultrasons (Utah) – Test de charge d’épreuve (1.5×WLL) |

MTC & rapports de tests disponibles |

| Interface de montage | ||

| Diamètre de la tige | 20mm ~ 300 mm | Tolérance: H7/g6 (DEPUIS 6885) |

| Type de broche | – Axe de chape (DEPUIS 688) – Alésage des yeux (DEPUIS 15403) |

Contre-écrous/goupilles fendues standard |

| Options de personnalisation | ||

| Caractéristiques spéciales | – Emplacements pour cellules de pesée – Rainures pour étiquettes RFID – Ports du capteur de verrouillage |

Prêt pour l'IoT/l'automatisation |

| Environnements extrêmes | – Cryogénique (-196° C) – Revêtement haute température (+650° C) – Antidéflagrant (ATEX/IECEx) |

Traitement cryogénique/thermique profond |

1. Wll & Facteur de sécurité

Résistance à la rupture minimale = WLL × facteur de sécurité (Par exemple, 100crochet: 500t charge de rupture)

Les charges dynamiques nécessitent un déclassement (suggéré: CMU × 1,2–1,5)

2. Ajouts de crochets pivotants

- Couple de rotation: ≤ 2% × CMU × D (D = diamètre de gorge) - Durée de vie des roulements: 100,000 cycles (ISO 281)

3. Comparaison de la protection contre la corrosion

| Type de revêtement | Environnement | Durée de vie (Industriel) |

| Électro-galvanisé | Sec à l'intérieur | 5–8 ans |

| Galvanisé à chaud | Humide/côtier | 15+ années |

| Revêtement Xylan® | Exposition chimique (pH 3–11) | 10 années |

1. Systèmes de ponts roulants (Eot, Portique, Foc)

2. Fonderies et aciéries

3. Fabrication de machines lourdes & Installation

4. Construction navale & Opérations en cale sèche

5. Exploitation minière & Traitement des minéraux

6. Production d'énergie (Turbine, Ascenseurs de transformateur)

7. Pont & Construction d’infrastructures majeures

8. Manutention des conteneurs du terminal portuaire & Opérations de transport lourd

Sécurité sans compromis: Construit selon les normes mondiales les plus élevées avec des marges de sécurité massives.

Fiabilité prouvée: La construction forgée et les matériaux haut de gamme garantissent des performances constantes dans les conditions les plus difficiles.

Durabilité supérieure: Le traitement thermique avancé et les finitions protectrices maximisent la durée de vie du crochet, réduisant les coûts de remplacement et les temps d'arrêt.

Excellence mondiale en ingénierie: Soutenu par le vaste R du groupe Weihua&D, prouesses de fabrication, et un contrôle qualité rigoureux.

Assistance complète: Réseau de vente et de service mondial fournissant des conseils d'experts, enregistré, et assistance à la maintenance.

Lorsque vos opérations exigent une certitude absolue sous des charges immenses, faites confiance à la solidité et à la fiabilité inébranlable des crochets de levage robustes Weihua. Ce ne sont pas que des crochets; ils constituent un composant de sécurité essentiel conçu pour fonctionner parfaitement, ascenseur après ascenseur.

Contactez Weihua ou votre distributeur agréé dès aujourd'hui pour discuter de vos besoins spécifiques en matière de levage de charges lourdes et découvrir la solution optimale de crochet de levage robuste pour vos applications les plus difficiles.. Visitez le site Web de Weihua pour les catalogues détaillés et les spécifications techniques.

Nous apprécions vos commentaires! Veuillez remplir le formulaire ci-dessous afin que nous puissions adapter nos services à vos besoins spécifiques.

Le crochet de grue de levage est le composant de charge central du système de grue et est dir ……

Découvrir plus →

Conçu pour une sécurité et une efficacité maximales, Le crochet de la grue Weihua avec un bloc de poulie ……

Découvrir plus →

Au cœur de chaque système de grue en tête fiable se trouve un composant critique: le cran ……

Découvrir plus →

Cliquez sur le bouton pour obtenir des informations et des citations de produits sur WhatsApp.

Obtenez un devis

Dernières commentaires