Your crane hook is the critical, final link between your lifting equipment and the load. Its failure isn’t just an operational hiccup; it’s a catastrophic safety hazard with potentially devastating consequences. Knowing when to replace your crane hook is not just good practice – it’s a fundamental safety and legal responsibility.

Ignoring worn or damaged hooks is a gamble no responsible operation can afford. Here’s your essential guide to recognizing the critical signs:

1. Visible Cracks: Any crack, no matter how small, is an absolute red flag. Cracks propagate under stress and lead to sudden, catastrophic failure. Replace immediately.

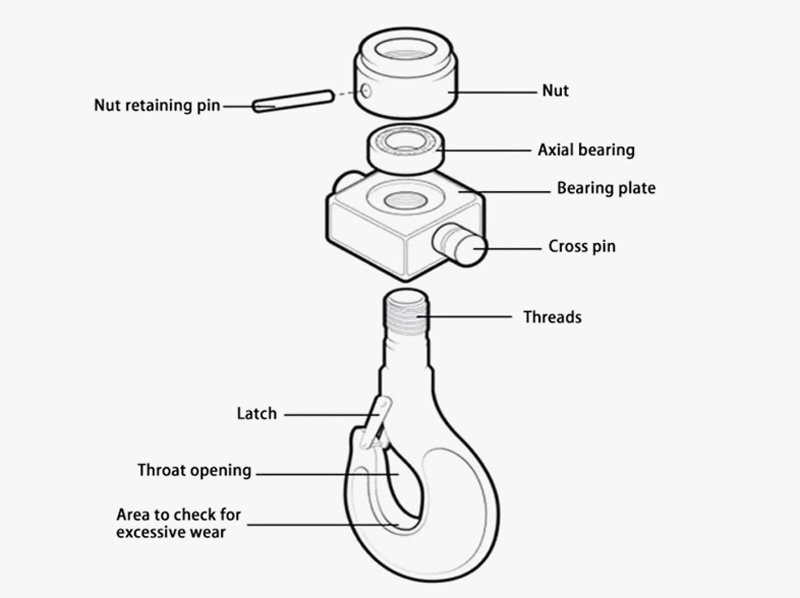

2. Excessive Wear: Measure the hook throat opening (at its widest point) regularly. If wear exceeds 10% of the original opening dimension, the hook’s capacity is compromised. Replace immediately.

3. Deformation/Bending: A hook should retain its original shape. Any twisting, bending, or opening of the hook beyond its manufactured tolerances indicates plastic deformation and severe weakening. Replace immediately.

4. Significant Neck Wear: Wear at the bottom of the hook’s neck (where it bears the load) reduces the cross-sectional area, drastically lowering its safe working load limit. If wear exceeds 5% of the original diameter, replace immediately.

5. Damaged or Missing Latch (Safety Latch): If equipped, a damaged, inoperative, or missing safety latch drastically increases the risk of slings or loads slipping off the hook. Repair or replace the hook/latch immediately.

6. Thread Damage (Shank Hooks): For hooks with threaded shanks, stripped, corroded, or damaged threads prevent proper seating and secure connection to the swivel or link. Replace immediately.

1. Deep Grooving or Notching: Deep scores or notches caused by abrasive wear or sharp edges on loads create dangerous stress points. Assess depth and location carefully; often warrants replacement.

2. Excessive Corrosion or Pitting: While surface rust might be cleanable, deep pitting corrosion eats away at the metal, reducing its strength significantly. Evaluate severity carefully.

3. Heat Damage (Discoloration): Blue or brown discoloration indicates the hook was exposed to high heat (e.g., welding sparks, fire), altering its metallurgy and weakening it. Likely requires replacement.

4. Hook Tip Wear: Significant wear on the hook tip can reduce its ability to securely retain slings or fittings.

5. Age and Service History: Even without obvious visible damage, hooks subjected to severe service cycles, heavy loads, or corrosive environments may need replacement based on manufacturer recommendations or engineering assessment.

6. After an Accident or Overload: Any hook involved in a shock load, overload incident, or collision must be removed from service immediately and thoroughly inspected by a competent person. Replacement is highly probable.

Regular Inspections are Mandatory: Implement a strict regime of:

Worker Injuries or Fatalities: This is the paramount risk.

Load Damage: Destruction of valuable cargo or equipment.

Property Damage: Collateral damage to structures or other assets.

Costly Downtime: Production halts and project delays.

Regulatory Fines & Penalties: Significant financial penalties for non-compliance.

Legal Liability & Lawsuits: Severe legal consequences for negligence.

Reputational Damage: Loss of client trust and business opportunities.

Remove Suspect Hook Immediately: Tag it “Out of Service” or “Do Not Use”.

Consult Standards & Manufacturer: Refer to the original equipment manufacturer (OEM) specifications and relevant standards (ASME B30.10, EN 1677, ISO 17096) for replacement criteria and compatible hook types.

Select the Correct Replacement: Match the rated capacity, type (shank, eye, clevis), material grade, and dimensions precisely. Never downgrade capacity.

Quality Matters: Source replacement hooks from reputable manufacturers that meet or exceed the required standards and provide certification.

Ensure Proper Installation: Follow OEM instructions meticulously. Torque requirements are critical for threaded shank hooks.

Inspect & Certify: Have the newly installed hook inspected and documented by a competent person before returning the crane to service. Proof load testing may be required depending on regulations or circumstance.

Destroy Old Hooks: Prevent accidental reuse – physically destroy severely damaged or failed hooks.

Your crane hook is a vital safety component. Treating replacement as a proactive necessity, not a reactive last resort, is key to protecting your people, your assets, and your business.

Schedule your next professional crane inspection today. Ensure every hook in your fleet is safe, compliant, and ready for the load. Contact our lifting experts for certified inspections, high-quality replacement hooks, and guidance on maintaining a safe lifting environment.

Q: Can a damaged hook be welded or repaired?

A: Welding or heat treatment repairs to crane hooks are generally prohibited by major standards (ASME B30.10) unless explicitly authorized by the OEM using qualified procedures. Replacement is almost always the required action.

Q: How often should hooks be formally inspected?

A: Frequency depends heavily on usage, environment, and regulations. Consult ASME B30.10, OSHA 1910.179, LOLER, or your local standards. Common intervals range from monthly (severe service) to annually (normal service), always performed by a competent person.

Q: Where can I find the original hook specifications?

A: Check the crane’s original documentation (load chart, manual), markings on the hook itself (capacity, grade, manufacturer), or contact the crane or hook OEM.

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.

Latest Comments