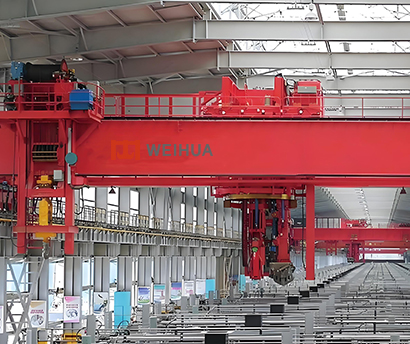

An overhead bridge crane is a heavy-duty material handling equipment designed to lift, przenosić, and position large or heavy loads horizontally across a fixed span.

An overhead bridge crane is a heavy-duty material handling equipment designed to lift, przenosić, and position large or heavy loads horizontally across a fixed span. Suspended from or mounted on elevated runways (typically along the length of a facility), it consists of a bridge structure that travels along these runways, with a hoist or trolley system that moves perpendicular to the bridge—enabling precise, multi-directional load movement.

Widely used in industrial settings, overhead bridge cranes streamline operations, reduce manual labor, and enhance safety when handling weights from a few tons to hundreds of tons. They are customizable to fit specific workspace dimensions, load requirements, i warunki środowiskowe, making them indispensable in manufacturing, logistyka, and heavy industries.

Overhead bridge cranes are engineered for reliability, efektywność, i bezpieczeństwo. Here are their core features:

Single girder overhead bridge crane

Choosing between single girder and double girder overhead bridge cranes depends on your load requirements, workspace, and budget. Here’s a breakdown:

|

Funkcja

|

Single Girder Overhead Bridge Crane

|

Double Girder Overhead Bridge Crane

|

|

Structure

|

One main girder (beam) supporting the hoist/trolley.

|

Two parallel girders with the hoist/trolley running between them.

|

|

Pojemność ładowania

|

Aż do 20 mnóstwo (standard); 50 mnóstwo (heavy-duty models).

|

20 tons and above (commonly 50–500+ tons).

|

|

Długość rozpiętości

|

Ideal for spans up to 30 metry.

|

Suitable for longer spans (aż do 50+ metry).

|

|

Wysokość podnoszenia

|

Moderate (limited by single girder strength).

|

Higher lifting heights (extra clearance due to dual girders).

|

|

Koszt

|

More affordable (simpler design, lower material use).

|

Wyższy koszt początkowy (sturdier build, larger components).

|

|

Najlepsze dla

|

Light to medium loads; small to medium facilities (NP., warsztaty, magazyny).

|

Heavy loads, large spans, or harsh environments (NP., Stalowe młyny, stoczni).

|

Below is a general parameter table for common overhead bridge crane models. Custom specifications are available based on your needs:

|

Model Type

|

Max Lifting Capacity

|

Długość rozpiętości

|

Wysokość podnoszenia

|

Klasa robotnicza (ISO/FEM)*

|

Zasilacz

|

Prędkość podnoszenia

|

|

Pojedynczy dźwigar (Standard)

|

1–20 ton

|

5–30 m

|

3–12 m

|

A3–A5

|

380V/3 fazy/50 Hz (custom)

|

0.5–10 m/min

|

|

Pojedynczy dźwigar (Ciężka)

|

20–50 tons

|

10–25 m

|

5–15 m

|

A5–A6

|

380V/3 fazy/50 Hz (custom)

|

0.3–8 m/mnie

|

|

Podwójny dźwigar (Standard)

|

20–100 tons

|

10–40 m

|

6–20 m

|

A6–A7

|

380V/3 fazy/50 Hz (custom)

|

0.2–6 m/min

|

|

Podwójny dźwigar (Ultra-Heavy)

|

100–500+ ton

|

15–50+ m

|

8–30 m

|

A7–A8

|

Zwyczaj (diesel/electric)

|

0.1–4 m/min

|

Klasa robotnicza: Indicates duty cycle (how often the crane operates under load). Higher classes (A7–A8) suit continuous, heavy-use environments.

Overhead bridge cranes are versatile across sectors requiring heavy material handling. Key applications include:

Follow these steps to select the perfect overhead bridge crane for your needs:

Q1: How often should an overhead bridge crane be inspected?

A: Daily visual checks (for wear, leaks, or loose parts) and annual professional inspections are mandatory. Heavy-use cranes (A7–A8) may require quarterly inspections.

Q2: Can overhead bridge cranes be automated?

A: Tak. Modern models can integrate with IoT systems for automated load tracking, scheduled movements, and remote operation—ideal for repetitive tasks.

Q3: What’s the lifespan of an overhead bridge crane?

A: With proper maintenance, single girder cranes last 15–20 years; double girder cranes can operate for 25–30 years or longer.

Q4: How is an overhead bridge crane installed?

A: Installation involves mounting runways to building columns or support structures, positioning the bridge, and integrating the hoist/trolley. Professional installation is recommended for safety.

Q5: What’s the difference between an overhead bridge crane and a gantry crane?

A: Overhead bridge cranes run on elevated runways (attached to a building), while Żuty grupy have ground-supported legs—making gantries better for outdoor or open spaces.

Ready to enhance your material handling efficiency? Contact us for a custom overhead bridge crane solution tailored to your industry and workflow.

Udostępnij w formacie PDF: Pobierać

Cenimy twoją opinię! Wypełnij poniższy formularz, abyśmy mogli dostosować nasze usługi do twoich konkretnych potrzeb.

The double girder overhead crane with electromagnet is a high-efficiency, heavy-duty li……

Odkryj więcej →

Działalność huty aluminium charakteryzuje się trudnymi warunkami pracy, wysoka temperatura……

Odkryj więcej →

Bęben linowy dźwigu służy jako rdzeń mechanizmu podnoszącego i, w niektórych przypadkach, trawersy……

Odkryj więcej →

Kliknij przycisk, aby uzyskać informacje o produkcie i cytaty na WhatsApp.

Zdobądź wycenę

Najnowsze komentarze