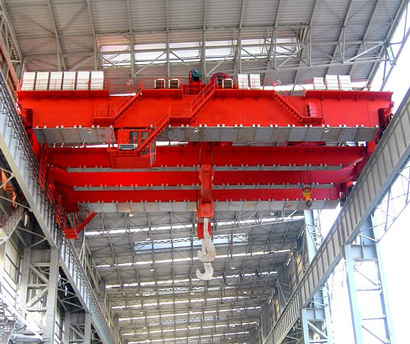

De 30 tons overhead crane is a core material handling equipment designed for medium-to-heavy industrial applications.

De 30 tons overhead crane is a core material handling equipment designed for medium-to-heavy industrial applications. It excels in lifting, bewegend, and positioning loads up to 30 tons with high precision, stability, en veiligheid, making it an indispensable asset for industries requiring efficient heavy-load transportation. Whether in manufacturing workshops, energiecentrales, or logistics yards, this crane optimizes workflow, reduces manual labor intensity, and ensures consistent operational efficiency.

De 30 tons overhead crane integrates advanced engineering, safety design, and user-friendly functionality, with the following key advantages:

|

Parameter Category

|

Specification Details

|

|

Nominaal hefvermogen

|

30 ton (main hook); 5-10 ton (auxiliary hook, optioneel)

|

|

Span Range

|

10 m – 31.5 M (customizable for special workshops)

|

|

Hefthoogte

|

6 m – 30 M (customizable based on workshop height)

|

|

Hefsnelheid (Main Hook)

|

0.8 – 8 m/mijn (variable frequency, stepless regulation)

|

|

Hefsnelheid (Aux Hook)

|

2 – 16 m/mijn (indien uitgerust)

|

|

Longitudinal Travel Speed (Kraan)

|

20 – 40 m/mijn (variable frequency)

|

|

Transverse Travel Speed (Karretje)

|

10 – 20 m/mijn (variable frequency)

|

|

Werkklasse

|

A5 – A7 (A5: medium-duty, 1,000 working hours/year; A7: heavy-duty, 4,000 working hours/year)

|

|

Stroomvoorziening

|

380V/50Hz/3Ph (customizable for 415V/60Hz for international markets)

|

|

Overall Weight

|

15 – 35 ton (varies by span and lifting height)

|

|

Motor Power (Hoisting)

|

18.5 – 37 kw (main hook); 5.5 – 11 kw (auxiliary hook, optioneel)

|

|

Motor Power (Longitudinal Travel)

|

2×7.5 – 2×15 kW (one motor per end beam)

|

|

Motor Power (Transverse Travel)

|

1×3 – 1×7.5 kW

|

De 30 tons overhead crane is widely used in industries that require heavy-load handling, thanks to its adaptability to different working environments:

While both models handle 30 ton, their structural designs and application scenarios differ significantly. The following table compares key aspects:

|

Vergelijkingsdimensie

|

Single-Girder 30 Ton bovenloopkraan

|

Double-Girder 30 Ton bovenloopkraan

|

|

Structural Design

|

Single main beam (I-beam or box beam) supported by end beams.

|

Two parallel main beams (box beams) connected by crossbeams.

|

|

Span Adaptability

|

Maximum span ≤ 22 M (limited by single-beam load-bearing capacity).

|

Maximum span ≥ 31.5 M (suitable for large workshops/yards).

|

|

Hefthoogte

|

Algemeen 6 – 18 M (limited by trolley installation space).

|

Algemeen 10 – 30 M (more vertical space for trolley movement).

|

|

Space Occupancy

|

Lower headroom (saves workshop height); smaller overall size.

|

Higher headroom (requires taller workshops); larger footprint.

|

|

Operational Stability

|

Moderate stability (prone to slight beam deflection under heavy loads).

|

High stability (dual beams distribute load evenly, minimal deflection).

|

|

Load Frequency

|

Suitable for medium-frequency operations (≤ 1,500 cycles/year).

|

Suitable for high-frequency operations (≥ 3,000 cycles/year).

|

|

Cost

|

Lower initial cost (30% – 50% cheaper than double-girder).

|

Higher initial cost (but lower long-term maintenance costs for heavy use).

|

|

Optional Configurations

|

Limited (auxiliary hook, remote control only).

|

Versatile (auxiliary hook, grab bucket, magnet, anti-sway system, enz.).

|

|

Ideal Scenarios

|

Small-to-medium workshops, low-frequency heavy-load handling (Bijv., small machinery factories).

|

Large workshops, high-frequency heavy-load handling (Bijv., staalfabrieken, energiecentrales).

|

Q1: What factors should I consider when selecting a 30 ton bovenloopkraan?

A1: Key factors include:

Q2: How often does a 30 tons overhead crane require maintenance?

A2: Maintenance follows a three-level schedule:

Q3: Can the 30 tons overhead crane be customized for special needs?

A3: Ja. Common customizations include:

Q4: What safety certifications are mandatory for 30 tons overhead cranes?

A4: Certifications vary by region, but key ones include:

Vraag 5: What is the service life of a 30 ton bovenloopkraan?

A5: Under normal use and proper maintenance, the service life is 10 – 15 years. Key factors affecting life include:

De 30 tons overhead crane combines power, veiligheid, and flexibility to meet the diverse needs of heavy-industry material handling. With customizable designs and reliable performance, it is a long-term investment for improving operational efficiency and ensuring workplace safety. For more details on models, quotes, or custom solutions, please contact our technical team.

Wij waarderen uw feedback! Vul het onderstaande formulier in, zodat we onze services kunnen aanpassen aan uw specifieke behoeften.

De 2 ton bovenloopkraan is een veelzijdige en betrouwbare hijsapparatuur ontworpen om te voldoen aan……

Ontdek meer →

Types of Warehouse Overhead Cranes and Their Applications 1. Single Girder Overhead Cr……

Ontdek meer →

Product Overview An overhead travelling crane, also known as an overhead crane or brid……

Ontdek meer →

Klik op de knop om productinformatie en offertes op WhatsApp te krijgen.

Krijg citaat

Laatste opmerkingen