Als je in de bouw werkt, productie, logistiek, of welke branche dan ook waarbij zware lasten moeten worden getild, je hebt ze talloze keren gezien: de gestempelde cijfers en letters op een kraanhaak. Maar heb je ooit stilgestaan bij de vraag wat ze eigenlijk betekenen??

Voor het ongetrainde oog, ze kunnen eruitzien als willekeurige serienummers. In werkelijkheid, ze zijn een cruciale veiligheidstaal: een directe boodschap van de fabrikant die u alles vertelt wat u moet weten over de mogelijkheden en beperkingen van de haak. Het negeren van deze markeringen is niet slechts een vergissing; het is een ernstig veiligheidsrisico.

Begrijpen hoe u deze markeringen moet lezen, is essentieel voor iedereen die betrokken is bij de planning, tuigage, of het goedkeuren van een lift. Laten we deze code ontleden en ervoor zorgen dat u met vertrouwen kunt interpreteren wat de hook u vertelt.

Fabrikanten volgen internationale normen (zoals ISO, ASME, of DIN) bij het markeren van haken. Terwijl de exacte indeling per merk enigszins kan verschillen, de essentiële informatie blijft consistent. Zoek naar deze markeringen die rechtstreeks op de haak zijn gestempeld, meestal op het zadel of de schacht.

1. Belastingswaarde / Werkbelastinglimiet (Wll)

Dit is het belangrijkste getal aan de haak. Het geeft de maximale kracht aan die de haak kan verwerken in een recht stuk, verticale lift. Het is niet het punt waarop de haak zal breken (dat is de ultieme lading), maar de maximale belasting die het veilig kan dragen onder normale bedrijfsomstandigheden.

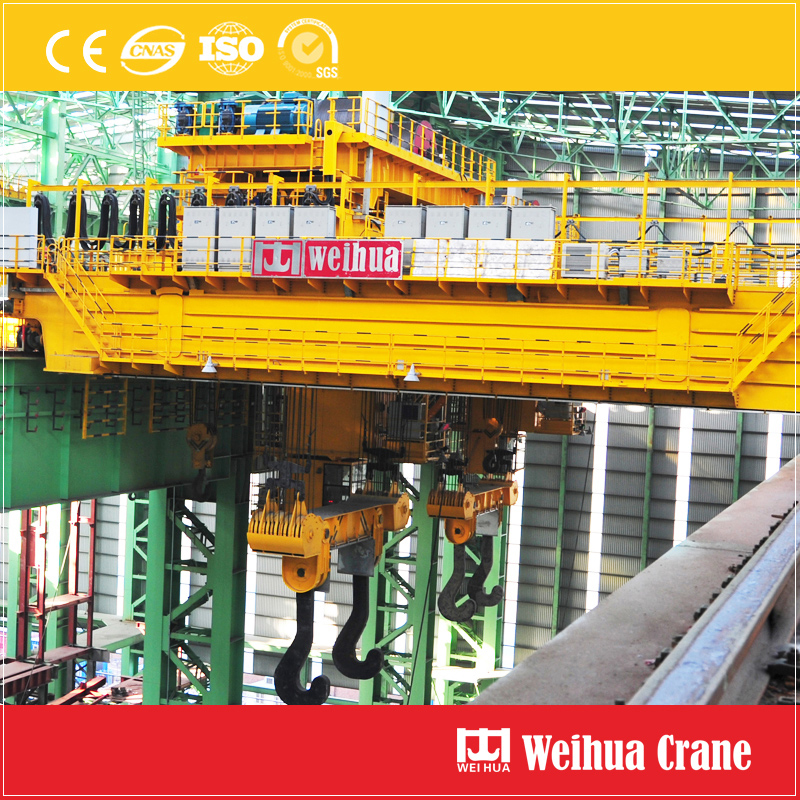

2. Logo of naam van de fabrikant

Dit identificeert het bedrijf dat de haak heeft ontworpen en vervaardigd. Gerenommeerde fabrikanten houden zich aan strikte kwaliteits- en testnormen. Als u het merk kent, kunt u de specificaties traceren en ervoor zorgen dat u originele gebruikt, gecertificeerde componenten.

3. Cijfer / Materiaalclassificatie

Deze markering specificeert de kwaliteit van het gelegeerd staal dat is gebruikt om de haak te smeden. Materialen van hogere kwaliteit hebben een hogere sterkte-gewichtsverhouding en worden vaak gebruikt voor veeleisende toepassingen.

4. Serienummer

Een unieke identificatie voor die specifieke hook. Dit is cruciaal voor de traceerbaarheid. In geval van een terugroepactie van een product, veiligheidswaarschuwing, of behoefte aan documentatie, Dankzij het serienummer kan de fabrikant de productiebatch en geschiedenis van de haak volgen.

5. Modelnummer

Dit identificeert het specifieke ontwerp en type haak. Er zijn verschillende modellen ontworpen voor verschillende toepassingen (Bijv., oog haken, schacht haken, gieterij haken, ramshoorn haken). Het modelnummer helpt u de juiste vervangende onderdelen te vinden en te verifiëren dat dit de juiste haak voor de klus is.

Stel je voor dat je een haak vindt met de volgende markeringen:

WEIHUA 20T S 12345ABC

Hier leest u hoe u het leest:

WEIHUA: De fabrikant.

20T: De werklastlimiet is 20 metrische ton.

S: De haak is gemaakt van hoogwaardige kwaliteit 120 legeringsstaal.

12345abc: Het unieke serienummer voor die haak.

Kraanhaak markeringen zijn een niet-onderhandelbaar onderdeel van de liftplanning en de veiligheid op locatie. Ze zijn snel, in één oogopslag garantie voor de identiteit en kracht van een haak. Als u een paar seconden de tijd neemt om deze informatie te lezen en te begrijpen, zorgt u ervoor dat het meest kritieke punt in uw lift (de verbinding tussen de kraan en de last) veilig is.

Wij waarderen uw feedback! Vul het onderstaande formulier in, zodat we onze services kunnen aanpassen aan uw specifieke behoeften.

Klik op de knop om productinformatie en offertes op WhatsApp te krijgen.

Krijg citaat

Laatste opmerkingen