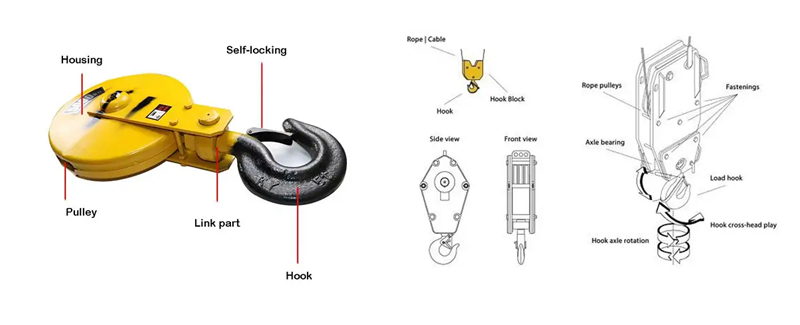

그만큼 60 톤 크레인 후크는 중장비 산업 응용 분야를 위해 설계된 중요한 리프팅 구성 요소입니다., 뛰어난 강도를 제공하도록 설계되었습니다., 신뢰할 수 있음, 까다로운 작업 환경에서의 안전. 글로벌 산업 표준을 준수하고 정밀하게 제작되었습니다., 이것 크레인 후크 건설 전반에 걸쳐 리프팅 작업의 중추 역할을 합니다., 조작, 기호 논리학, 및 해양 부문, 안전하고 효율적인 화물 처리 보장 60 톤.

|

매개 변수

|

사양

|

|---|---|

|

정격 부하 용량

|

60 톤 (600 kN)

|

|

재료

|

20MnSi / 35CrMo 합금강

|

|

열처리

|

담금질 + 템퍼링 (큐&티)

|

|

후크 목구멍 개구부

|

맞춤형 (일반적으로 150-300 mm, 요구 사항을 기반으로)

|

|

후크 재질 경도

|

HB 220-260

|

|

표면 처리

|

핫 다프 아연 도금 / 정전기 분사 / 크롬 도금

|

|

안전 걸쇠

|

탄소강 / 스테인레스 스틸 (옵션/표준)

|

|

표준 준수

|

ISO 16620, GB/T 10051, FEM 1.001

|

그만큼 60 톤 크레인 후크는 크고 무거운 하중을 안정적으로 들어 올리는 것이 필수적인 다양한 중공업 분야에서 널리 활용됩니다.. 주요 애플리케이션 시나리오는 다음과 같습니다.:

우리는 모든 면에서 안전과 품질을 최우선으로 생각합니다 60 우리가 생산하는 톤 크레인 후크. 각 후크는 엄격한 품질 관리 절차를 거칩니다., 포함:

당사의 제품은 ISO 등 국제 표준을 준수합니다. 16620, GB/T 10051, 그리고 FEM 1.001, 권위있는 기관의 인증을 받았습니다. (예를 들어, CE, SGS, CCC) 글로벌 시장 접근과 사용자 신뢰를 보장하기 위해.

메모: 맞춤형 요구 사항 (예를 들어, 특수 후크 목 크기, 표면 처리, 또는 안전 액세서리), 영업팀에 문의해 주세요. 우리는 귀하의 특정 리프팅 요구 사항을 충족하는 맞춤형 솔루션을 제공합니다..

Q1: 서비스 수명은 얼마나 됩니까? 60 톤 크레인 후크?

에이: 서비스 수명은 일반적으로 5 에게 10 연령, 사용빈도에 따라, 작업 환경, 유지 관리 프로토콜 준수. 정기적인 점검과 적절한 유지관리 (예를 들어, 매끄럽게 하기, 부식 방지) 서비스 수명을 크게 연장할 수 있습니다..

Q2: 극한의 온도 환경에서 크레인 후크를 사용할 수 있습니까??

에이: 예. 20MnSi/35CrMo 합금강 및 열처리 공정을 통해 -20°C ~ 120°C 범위의 온도에서 작동 가능. 특별한 극한 온도 요구 사항에 적합 (예를 들어, -20°C 이하 또는 120°C 이상), 맞춤형 재료 솔루션에 대해서는 당사 팀에 문의하십시오..

Q3: 크레인 후크를 얼마나 자주 검사해야 합니까??

에이: 사용 전 매일 육안 검사를 실시하는 것이 좋습니다. (균열 확인, 흉한 모습, 또는 안전 걸쇠 손상) 그리고 포괄적인 비파괴 테스트 (ndt) 모든 6 몇 달 또는 그 이후 500 영업 시간, 어느 쪽이든 먼저 오는 것.

Q4: 안전 걸쇠는 필수인가요?, 그리고 손상된 경우 교체할 수 있나요??

에이: 안전 래치는 표준 및 옵션으로 제공됩니다.. 손상된 경우, 호환성과 안전성을 보장하기 위해 당사에서 제공하는 순정 부품으로 교체할 수 있습니다.. 로드 보안을 손상시킬 수 있으므로 정품이 아닌 래치를 사용하지 마십시오..

Q5: 맞춤형 크레인 후크 주문에 필요한 정보는 무엇입니까??

에이: 맞춤 주문을 처리하려면, 필요한 정격 부하와 같은 세부 정보를 제공해 주십시오. (확인 60 톤 또는 조정), 후크 목 구멍 크기, 표면 처리 유형, 안전 액세서리 요구 사항 (예를 들어, 스테인레스 스틸 래치), 준수해야 할 특정 산업 표준.

Q6: 제품에 설치 지침이 함께 제공됩니까??

에이: 예. 각 크레인 후크에는 자세한 설치 설명서가 함께 제공됩니다., 연결 다이어그램 포함, 패스너의 토크 요구 사항, 설치 중 안전 예방 조치. 필요한 경우 당사 기술팀이 원격 안내도 제공합니다..

PDF로 공유: 다운로드

우리는 귀하의 의견을 소중히 여깁니다! 귀하의 특정 요구에 맞게 서비스를 조정할 수 있도록 아래 양식을 작성하십시오..

최신 의견