A Single Girder Electric Overhead Traveling (Eot) Crane is a fundamental and highly versatile piece of material handling equipment. It is designed for efficiently moving heavy loads horizontally and vertically within a defined workspace, typically a factory, entrepôt, or workshop.

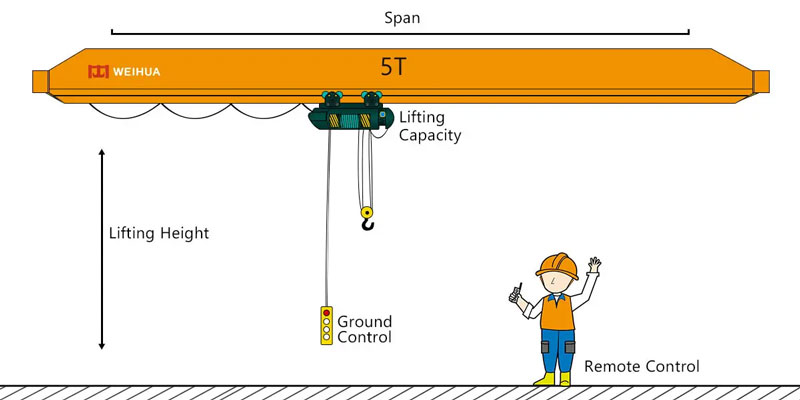

The core structure of the single girder eot crane consists of a bridge supported at both ends by end cars running along the runway beam. A crane and trolley mechanism moves along the bottom flange of the main beam, providing lifting and lateral movement. Single girder EOT cranes are known for their cost-effectiveness, simplicity and reliability, making them the ideal solution for a variety of light to medium duty applications. The crane operates on elevated runway rails, freeing up valuable floor space below.

1. Cost-Effective Solution

Due to its simpler design with only one main girder, this crane type requires less material and is more economical to manufacture and install compared to a double girder crane, offering excellent value for money.

2. Compact and Space-Saving Design

The single girder structure has a lower headroom, making it perfect for facilities with height restrictions. This maximizes the usable lifting height under the hook.

3. Robust and Reliable Performance

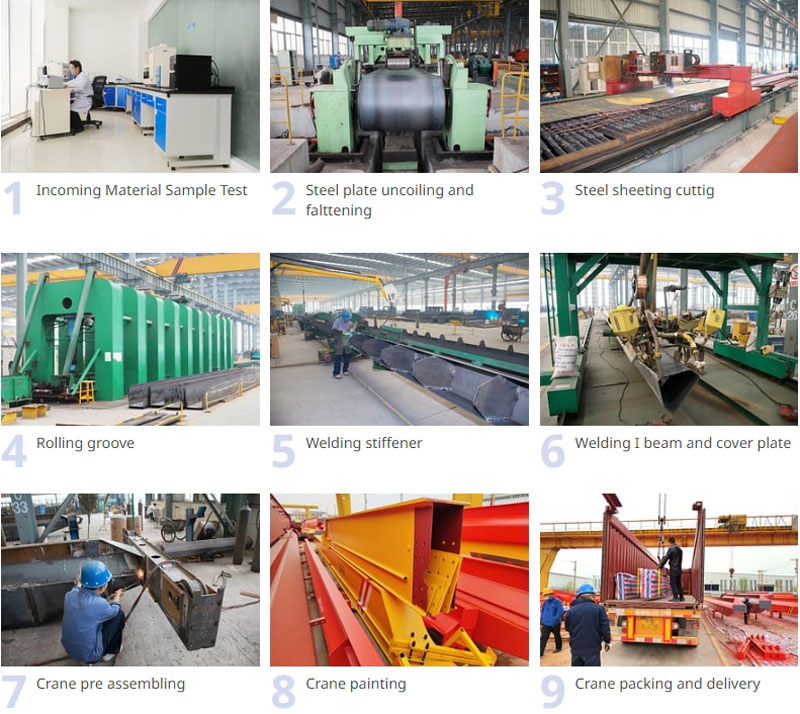

Built from high-quality steel, the main girder is designed to withstand rigorous use with minimal deflection. The entire structure ensures stable and reliable operation over a long service life.

4. Easy Installation and Low Maintenance

The simple design translates to easier and faster installation. With fewer components than more complex cranes, maintenance is straightforward, and operational downtime is reduced.

5. Smooth and Precise Operation

Equipped with high-quality electric hoists and driven end carriages, these cranes provide smooth travel, precise load positioning, and quiet operation, enhancing workplace safety and efficiency.

6. Caractéristiques de sécurité améliorées

Standard safety equipment includes overload limit switches, end limit switches for both bridge and hoist travel, boutons d'arrêt d'urgence, and thermal protection for motors, ensuring a secure working environment.

7. Options de personnalisation

While a standard product, these cranes can be customized with various hoist capacities, travées, lifting speeds, and control options (pendant control or radio remote control) to meet specific application needs.

The following table outlines standard specifications. Custom configurations are available.

| Paramètre | Gamme de spécifications | Notes |

| Capacité de levage | 1 Tonne à 20 Tonnes | Standard capacities; custom designs available. |

| Portée | 5 Meters to 25 Meters | The distance between runway rails. |

| Hauteur de levage | Jusqu'à 30 Meters | Customizable as per requirement. |

| Devoir de travail | A3 / Classe 2 (Light to Moderate) | Suitable for intermittent service. |

| Mode de contrôle | Contrôle du pendentif / Radio Remote Control | Wired pendant is standard; wireless remote is optional. |

| Alimentation électrique | 3 Phase, 380V / 400V / 415V, 50HZ | Can be adapted to local power standards. |

| Température ambiante | -20° C à + 40 ° C | Suitable for most industrial environments. |

| Vitesse de déplacement | 20 m / mon (Env.) | Speed of the crane along the runway. |

| Vitesse de levage | 8 m / mon (Env.) | Speed of lifting/lowering the load. |

Single Girder EOT Cranes are workhorses across numerous industries:

Q1: What is the main difference between a Single Girder and a Double Girder EOT Crane?

UN: A Single Girder crane has one main beam supporting the hoist, which runs on the bottom flange. A Double Girder has two main beams, with the hoist running between them on a top-mounted trolley. Double girder cranes are used for heavier capacities (>20T), require higher headroom, and are more expensive but offer greater hook height.

Q2: Can the crane be used outdoors?

UN: Oui, but it requires specific modifications. An outdoor crane would typically be supplied with an IP54 or higher protection rating, anti-corrosion paint, and other features like wind hooks to secure it when not in use.

Q3: How is the crane powered?

UN: The most common method is via a festoon system or conductor bars that run along the runway, providing continuous power to the crane. Alternatively, cable reels can be used.

T4: What maintenance is required?

UN: Regular maintenance includes visual inspections, checking for wear on wheels and brakes, ensuring electrical components are functional, and lubricating moving parts. An annual professional inspection is highly recommended.

Q5: Can I increase the capacity of my existing Single Girder crane later?

UN: Non. Cranes are designed and built for a specific maximum capacity. Attempting to exceed this rating is extremely dangerous. The entire structure, including the girder, chariots d'extrémité, et lever, is rated for the original capacity.

Q6: How do I choose the right capacity and span?

UN: You must know the maximum weight of the loads you will be lifting and the exact distance between the runway support columns in your facility. It is always advisable to consult with our engineering team to ensure a safe and optimal design.

Nous apprécions vos commentaires! Veuillez remplir le formulaire ci-dessous afin que nous puissions adapter nos services à vos besoins spécifiques.

Présentation du produit Le pont roulant à faible hauteur libre est une machine spécialisée dans la manutention des matériaux……

Découvrir plus →

Steel Coil Handling Overhead Crane For Sale Designed exclusively for the rigorous deman……

Découvrir plus →

Aluminium smelter operations are characterized by harsh working environments, high-temp……

Découvrir plus →

Cliquez sur le bouton pour obtenir des informations et des citations de produits sur WhatsApp.

Obtenez un devis

Dernières commentaires