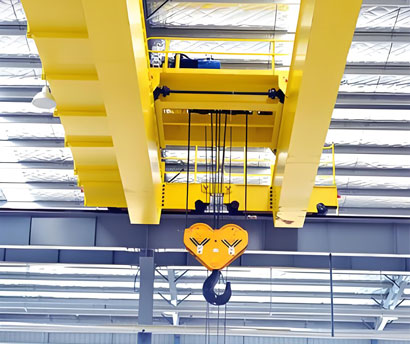

Dans le monde du levage de charges lourdes, few scenarios are as nerve-wracking and dangerous as crane hook slippage. That moment when a load shifts, a sling slips, and the immense weight you're suspending in the air is no longer secure. The consequences can be catastrophic: damaged equipment, lost loads, retards du projet, et surtout, severe injury or loss of life.

Empêcher le glissement de crochet n'est pas seulement une meilleure pratique; it’s a fundamental pillar of crane safety. It’s about understanding the physics of lifting and respecting the equipment that makes it all possible. Let’s break down the causes and, surtout, the proven strategies for prevention.

Understanding the root causes is the first step to prevention. Slippage typically occurs due to one or a combination of these factors:

Prevention is a multi-step process that involves the right equipment, the right knowledge, and unwavering vigilance.

1. The Power of the Latch: Never Bypass It

The hook safety latch is your first and most mechanical line of defense. It acts as a barrier, preventing the sling from jumping out of the hook bowl.

2. Master Rigging and Hitch Selection

The way you attach the load is everything.

3. Implement Redundancy with Secondary Attachment

For critical lifts or when there’s any doubt, add a secondary safety measure.

4. Rigorous Inspection and Maintenance

A damaged hook is an accident waiting to happen.

5. Continuous Training and Communication

Human error is a significant factor.

Crane hook slippage is a preventable event. It requires a culture of safety where every team member is empowered to stop a lift if something looks wrong. By respecting the equipment, mastering rigging techniques, insisting on functional safety latches, and committing to continuous training, we can ensure that every load is secured, every lift is controlled, and every worker goes home safely.

Nous apprécions vos commentaires! Veuillez remplir le formulaire ci-dessous afin que nous puissions adapter nos services à vos besoins spécifiques.

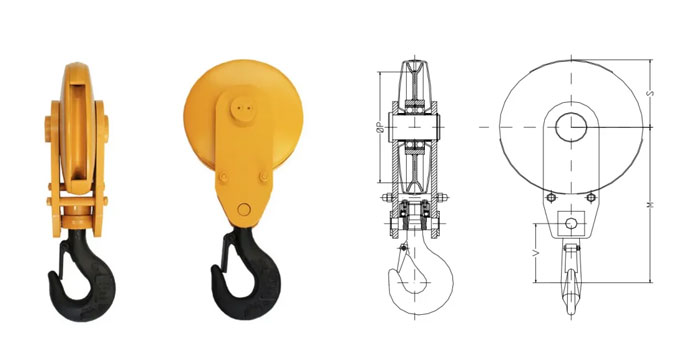

L'assemblage de blocs de crochet aérien est le fondamental, composant robuste responsable ……

Découvrir plus →

Conçu pour exiger le levage industriel, le weihua 50 Ton Crane Hook est un CR ……

Découvrir plus →

Notre solution à crochet Crane Tucson dispose d'un système de crochet lourd conçu pour Secure Lif ……

Découvrir plus →

Cliquez sur le bouton pour obtenir des informations et des citations de produits sur WhatsApp.

Obtenez un devis

Dernières commentaires