A 20 ton overhead crane is a fundamental piece of industrial lifting equipment designed for heavy-duty material handling in workshops, sklady, fabrication plants, ocelárny, and other industrial settings. It operates on elevated runways, maximizing floor space and providing unparalleled lifting capacity and coverage across a work area. This guide provides a comprehensive look at 20-ton cranes, including types, features, stanovení cen, and specifications.

The primary distinction in 20-ton overhead cranes is between single girder and double girder designs. The choice depends on your application’s specific requirements for frequency, rozpětí, and duty cycle.

A single girder crane features one main beam (girder) upon which the hoist and trolley travel. The hoist is typically mounted under the girder.

Nejlepší pro: Applications with lighter duty cycles, shorter spans (typically up to 30 metry), and where cost-effectiveness is a primary concern.

Key Characteristics:

Limitation: Generally not suitable for extremely heavy-duty, continuous (CIC – Continuous Intermittent Cycle) applications or very long spans.

Aplikace

20 Ton Single Girder Electric Overhead Travelling Crane

20 Ton Explosion Proof Single Girder Overhead Crane

20 Ton Low Headroom Single Girder Overhead Crane

A double girder crane features two main beams that support a trolley that runs on top of the girders. The hoist is mounted on this trolley.

Nejlepší pro: Severe-duty applications, longer spans (over 30 metry), higher duty cycles (CIC), and situations requiring maximum hook height.

Key Characteristics:

Limitation: Higher initial cost and weight, and requires more headroom.

Aplikace

20 Ton Double Girder Overhead Crane with Hoist Trolley

20 Ton Grab Bucket Overhead Crane

| Parametr | 20 Ton Single Girder Crane | 20 Ton Double Girder Crane |

| Kapacita | 20 Tuny | 20 Tuny |

| Rozpětí (S) | Up to ~30 meters | Zvyk, often over 30 metry |

| Výška zvedání (H) | Zvyk (NAPŘ., 6m, 9m, 12m) | Zvyk (NAPŘ., 9m, 12m, 18m) |

| Pracovní povinnost | A3 / FEM 1Am (Light – Moderate) | A4-A7 / FEM 2m-4m (Moderate – Severe) |

| Operating Speed | ||

| – Hoisting | 8.0 m/můj (cca.) | 3.3 - 20 m/můj (variable frequency drive) |

| – Long Travel | 20-30 m/můj (cca.) | 20-100 m/můj (variable frequency drive) |

| – Cross Travel | 10-20 m/můj (cca.) | 20-40 m/můj (variable frequency drive) |

| Režim řízení | Ovládání přívěskem / Radio Remote | Ovládání přívěskem / Radio Remote / Cab |

| Napájení | 3-Fáze, 380V/400V/415V, 50Hz/60Hz | 3-Fáze, 380V/400V/415V, 50Hz/60Hz |

| Okolní teplota | -20°C až +40 °C (Norma) | -25°C to +45°C (Norma) |

20 Ton Double Girder Overhead Crane

Providing an exact price is impossible without specific project details. A 20 ton overhead crane price is highly variable and depends on:

Price Range: A basic 20 ton single girder overhead crane might start around $15,000 - $25,000, while a custom, large-span, double girder overhead crane can easily exceed $50,000 - $100,000+. Always request a detailed quotation from a supplier.

The delivery lead time for a WEIHUA 20 ton overhead crane is not a fixed number but depends on several key factors related to the project’s complexity and customization. Obvykle, for a standard specification crane, the lead time ranges from 40 na 60 working days after the final order confirmation and receipt of down payment.

For more complex or heavily customized projects, the lead time can extend to 60-90 working days or more.

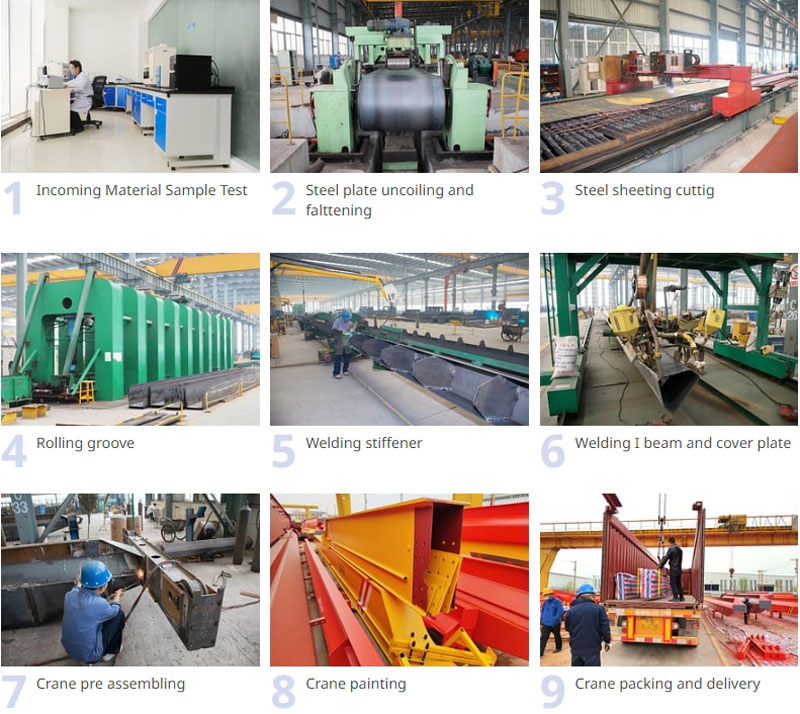

The following table breaks down the typical stages of the process and the factors that influence the timeline:

| Fáze | Estimated Duration (Working Days) | Key Influencing Factors |

| 1. Engineering & Technical Clarification | 5 - 10 dní | Typ jeřábu: A standard 20-ton single girder crane requires less engineering than a double girder or customized crane. Přizpůsobení: Special requirements (NAPŘ., special paint, extra safety devices, unique dimensions) lengthen this phase. |

| 2. Procurement of Raw Materials & Components | 5 - 10 dní | Component Brand: Using standard, in-stock components speeds up the process. Specific requests for premium or non-standard brands (NAPŘ., a specific motor or inverter brand) can cause delays. Material Availability: Market availability of steel and other raw materials. |

| 3. Výrobní & Shromáždění | 15 - 25 dní | Production Schedule: This is the core production time for fabricating girders, assembling hoists, and building end carriages. Workshop Workload: Peak seasons can lead to longer queues. |

| 4. Factory Testing & Inspekce (FAT) | 3 - 5 dní | Customer Requirements: If a mandatory Factory Acceptance Test (FAT) is required, it is scheduled in this period. |

| 5. Obal & Preparation for Shipment | 2 - 5 dní | Packaging Type: Standard export wooden case packaging is typical. Special packaging requirements may take longer. |

| 6. Shipping & Logistika | Variable | Destination: Domestic shipping within China is fastest. International shipping (by sea or air) depends on the destination port and shipping schedules. Incoterms: The terms of trade (NAPŘ., FOB, CIF) define who arranges logistics and affects the overall timeline to your site. |

WEIHUA Factory

1. Single Girder vs. Double Girder: A 20 ton single girder overhead crane has a simpler design and is often faster to produce. A 20 ton double girder overhead crane is more complex, requiring more engineering and manufacturing time.

2. Level of Customization: Standard cranes are delivered fastest. Customizations like:

3. Order Quantity: A single crane order will follow the standard timeline. A larger order for multiple cranes will naturally take longer, though there may be some efficiency gains.

4. Component Availability: WEIHUA manufactures many core components, which helps control the supply chain. Však, if you specify third-party branded components, their lead time must be factored in.

Q1: Which is better for my workshop, a single or double girder 20 tunový mostový jeřáb?

A: If your usage is occasional, spans are short, and budget is key, a single girder is likely sufficient. For daily, intensive use, long spans, or needing maximum hook height, a double girder is the better, more durable investment.

Q2: What maintenance is required for a 20 tunový mostový jeřáb?

A: Regular inspections are essential. Daily checks by the operator, periodic inspections by a supervisor (monthly/quarterly), and a full annual inspection by a qualified technician are recommended to ensure safety and longevity.

Selecting the right 20-ton lifting equipment is a strategic decision that impacts your operation’s safety, účinnost, and productivity. By understanding the differences between single and double girder cranes, as well as alternatives like gantry and jib cranes, you can make an informed choice. Contact us today for a free consultation and a customized quotation for your 20-ton overhead crane solution.

Q3: How to get a precise delivery date?

A: To receive a firm delivery date, it is essential to provide WEIHUA with your detailed requirements. A formal quotation will include a specific lead time.

For the most accurate and competitive offer, please contact us with your specifications.

We, WEIHUA, are committed to providing high-quality cranes and reliable delivery schedules. We understand that your project timeline is critical and will work closely with you to ensure a smooth process from order to delivery.

WEIHUA Overhead Crane PDF Information: Stáhnout

Vážíme si vaší zpětné vazby! Vyplňte prosím níže uvedený formulář, abychom mohli přizpůsobit naše služby vašim konkrétním potřebám.

Úvod Když váš provoz vyžaduje spolehlivost, efektivní zvedání 8tunových břemen, Ó……

Objevte více →

Jako základní zařízení pro nakládku a vykládku kontejnerů v popředí moderní po……

Objevte více →

The metallurgical double girder overhead crane is a specialized lifting equipment tail……

Objevte více →

Kliknutím na tlačítko získáte informace o produktu a nabídky na WhatsApp.

Získejte citát

Nejnovější komentáře