V oblasti manipulace s materiálem a průmyslových provozů, overhead cranes stand as indispensable workhorses, designed to lift, pohyb, and position heavy loads with precision and efficiency. Also known as bridge cranes, these mechanical systems are widely used across various sectors, from manufacturing plants and warehouses to construction sites and shipping yards. Their ability to navigate large workspaces while minimizing floor space usage makes them a cornerstone of modern industrial logistics.

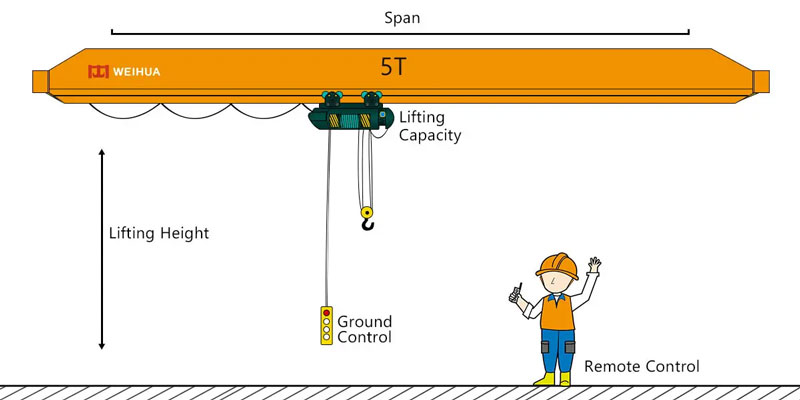

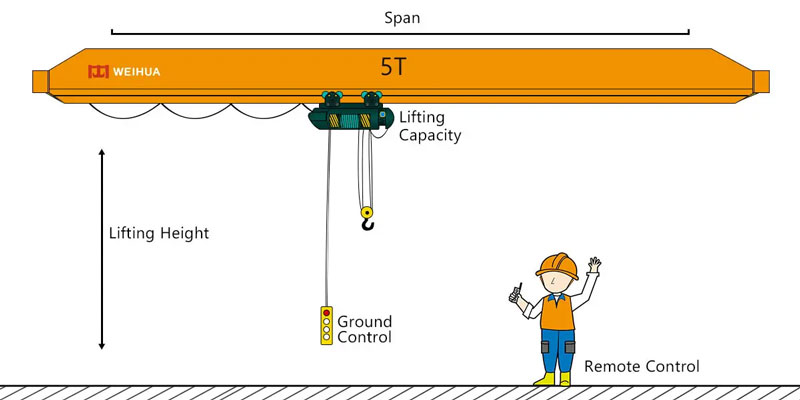

Core Components of an Overhead Crane

An overhead crane consists of several key components that work in tandem to perform lifting tasks. Understanding these parts is essential to grasp how the crane operates:

- 1. Mostní nosník: The main horizontal beam that spans the width of the workspace, often referred to as the “bridge.” It is typically constructed from robust materials like steel to support the weight of the load and other components. The bridge rests on end trucks, which enable it to move along the runways.

- 2. End Trucks: Located at both ends of the bridge girder, these assemblies house the wheels and motors that drive the crane’s movement along the elevated runways. The runways are fixed to the building’s structure or supported by columns, defining the crane’s horizontal travel path.

- 3. Vozík: A movable unit that travels along the length of the bridge girder. It carries the hoist and is powered by its own motor, allowing for precise positioning of the load along the bridge’s span.

- 4. Vztyčit: The lifting mechanism of the crane, consisting of a motor, gearbox, buben, and cable or chain. The elektrický kladkostroj is responsible for raising and lowering the load, with the cable/chain attached to a hook or other lifting accessory (such as a spreader bar for bulky items).

- 5. Řídicí systém: The interface used to operate the crane, which can be manual (via a pendant control station) or automated (integrated with computer systems for programmed movements). Modern cranes may also feature remote controls for enhanced operator safety and flexibility.

How Does an Overhead Crane Work?

The operation of an overhead crane involves three primary axes of movement, working together to transport loads from one location to another:

- 1. Bridge Travel: The end trucks drive the bridge girder along the runways, moving the entire crane assembly horizontally across the workspace. This allows the crane to cover the width of the area it serves.

- 2. Trolley Travel: The trolley moves along the bridge girder, shifting the hoist and load along the length of the bridge. This enables precise positioning of the load within the crane’s span.

- 3. Hoist Lifting/Lowering: The hoist motor rotates the drum, winding or unwinding the cable/chain to raise or lower the load. The speed and force of the hoist are carefully controlled to ensure smooth and safe handling of heavy objects.

By coordinating these three movements, operators can maneuver loads with accuracy, even in tight or crowded industrial environments. Many modern overhead cranes also incorporate sensors and safety features (such as limit switches and overload protection) to prevent accidents and ensure compliance with safety standards.

Common Applications of Overhead Cranes

Overhead cranes are versatile and find applications in a wide range of industries due to their ability to handle heavy and bulky loads. Some of the most common uses include:

- 1. Výrobní: In automotive, Aerospace, and heavy machinery plants, overhead cranes are used to move raw materials (NAPŘ., ocelové cívky, bloky motoru) between production stations, assemble large components, and load/unload finished products onto trucks or trains.

- 2. Warehousing and Logistics: In distribution centers and warehouses, cranes facilitate the storage and retrieval of heavy pallets, kontejnery, or equipment from high shelves, maximizing vertical storage space and improving inventory management efficiency.

- 3. Konstrukce: Na stavbách, mostové jeřáby (often temporary installations) lift and place structural elements such as steel beams, Betonové panely, and machinery to heights that would be impossible with other lifting equipment.

- 4. Shipping and Ports: Container ports use large overhead cranes (known as gantry cranes, a type of overhead crane) to load and unload shipping containers from cargo ships, streamlining the movement of goods in global trade.

- 5. Těžba a těžký průmysl: In mines and smelting facilities, overhead cranes handle heavy ore containers, molten metal ladles, and large machinery parts, operating in harsh environments that require durable and reliable equipment.

Safety Considerations for Overhead Crane Operation

Safety is paramount when operating overhead cranes, given their ability to lift extremely heavy loads. Key safety practices and features include:

- 1. Školení operátorů: All crane operators must undergo specialized training and certification to understand the equipment’s capabilities, limitations, and safe operating procedures.

- 2. Load Capacity Checks: Cranes must never be overloaded. Each crane is rated for a maximum load capacity, which is clearly marked and must be strictly adhered to. Overload protection devices automatically shut down the hoist if the load exceeds the limit.

- 3. Regular Inspections and Maintenance: Routine inspections (daily, weekly, and annual) are required to check for wear and tear on components like cables, Háčky, and motors. Preventive maintenance ensures the crane operates reliably and reduces the risk of mechanical failure.

- 4. Clear Workspace: The area beneath and around the crane must be kept clear of personnel and obstacles during operation. Warning signs and barriers are often used to demarcate the crane’s working zone.

- 5. Emergency Stop Controls: All cranes are equipped with emergency stop buttons that allow operators to halt all movements immediately in case of a hazard.

Technological Advancements in Overhead Cranes

Like many industrial technologies, overhead cranes have evolved significantly with advancements in automation, connectivity, and data analytics. Some of the latest innovations include:

- 1. Automated and Semi-Automated Operation: Automated overhead cranes (AOCs) use sensors, kamery, and computer algorithms to perform repetitive tasks (such as loading/unloading conveyors) without human intervention. Semi-automated systems assist operators with features like anti-sway control and precise positioning.

- 2. IoT Connectivity: Smart cranes are equipped with IoT (Internet věcí) sensors that collect data on performance, maintenance needs, and load usage. This data is transmitted to a central system for real-time monitoring, predictive maintenance, and operational optimization.

- 3. Energetická účinnost: Modern cranes incorporate energy-saving technologies such as regenerative braking (which captures and reuses energy during lowering) and variable frequency drives (VFDs) that adjust motor speed to match the load, reducing power consumption.

- 4. Vylepšené bezpečnostní systémy: Advanced safety features include collision avoidance systems (to prevent cranes from colliding with each other or obstacles), laser positioning, and load moment indicators (which calculate the stability of the load based on its weight and position).

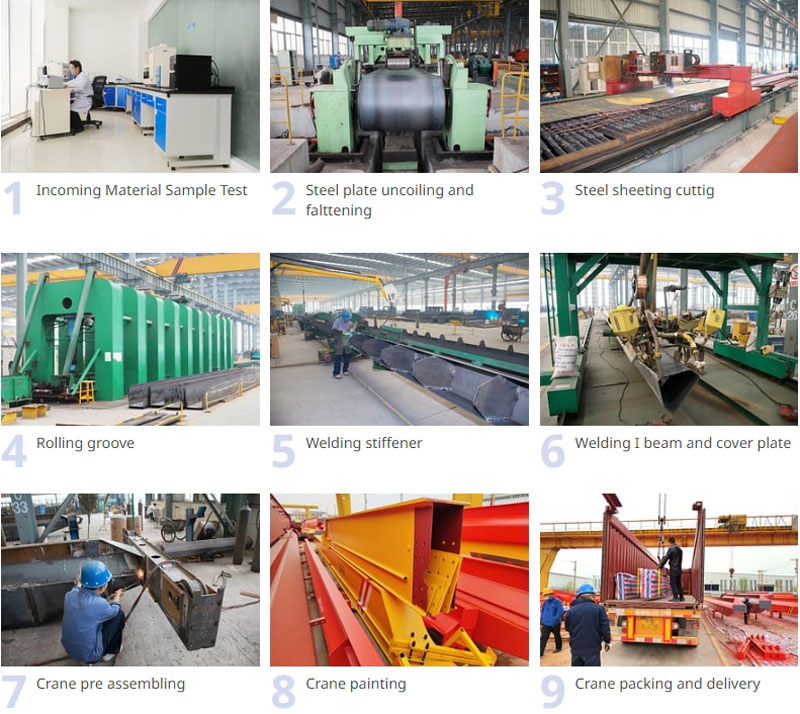

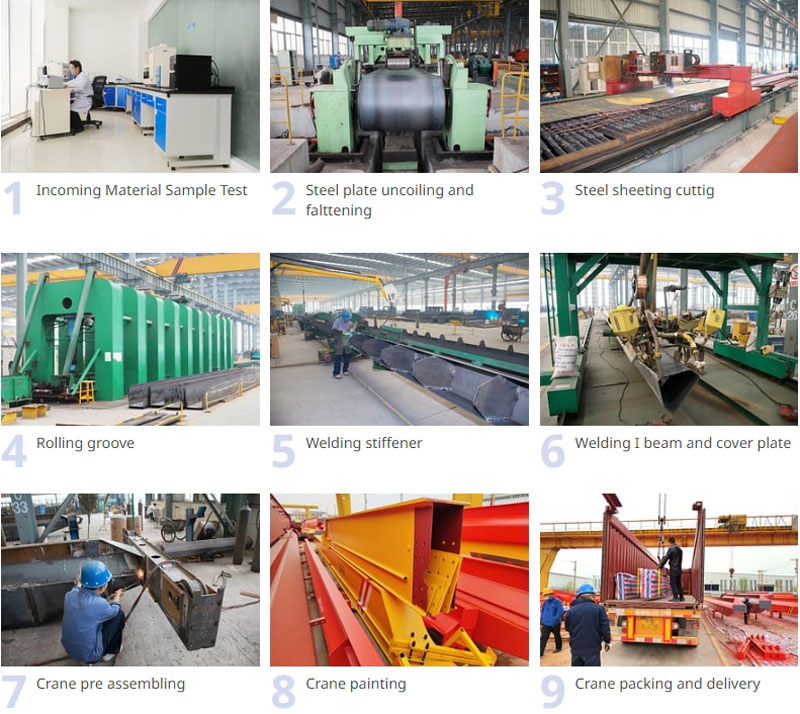

Overhead crane manufacturing process

Mostové jeřáby are vital assets in industrial operations, enabling the efficient and safe handling of heavy loads across diverse sectors. From their core components and multi-axis movement to their wide-ranging applications and ongoing technological advancements, these cranes play a crucial role in improving productivity, reducing manual labor, and ensuring workplace safety. As industries continue to demand higher efficiency and automation, overhead cranes will remain at the forefront of material handling innovation, adapting to meet the evolving needs of the global manufacturing and logistics landscape.

Nejnovější komentáře