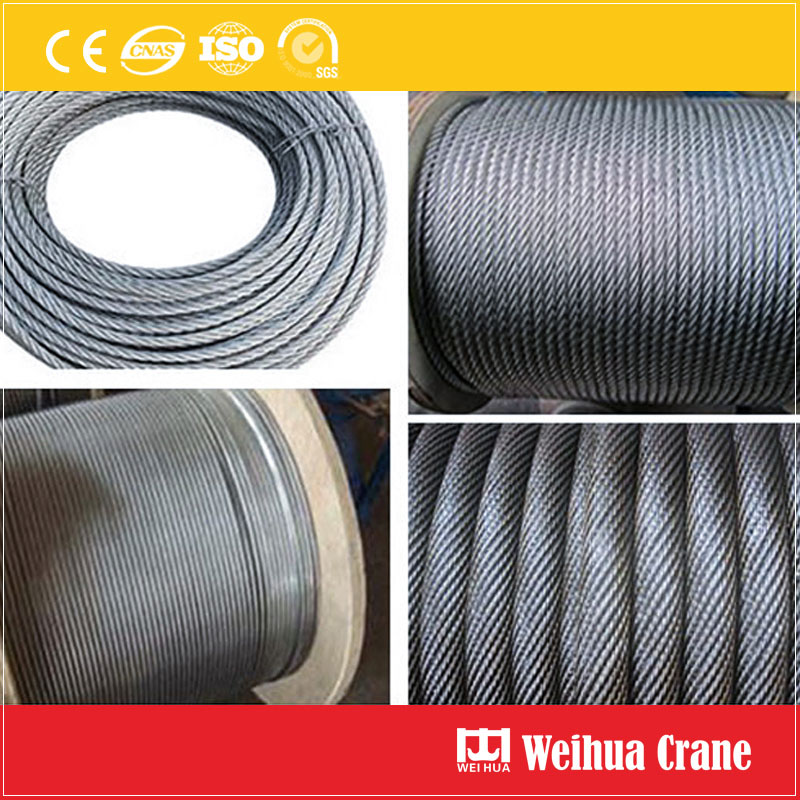

起重机钢丝绳是起重设备中使用的关键部件, 起重和牵引设备. 由多股钢丝绞合而成,具有强度高的特点, 耐磨、耐腐蚀. 广泛应用于桥式起重机, 龙门起重机, 集装箱起重机, 电动葫芦, ETC.

在苛刻的物质处理世界中, 建造, 和举重, 每个组件都必须具有坚定的可靠性. 这些关键操作的核心是起重机钢丝绳,该产品的设计不仅仅是为了提升, 但要忍受, 确保, 并赋予权力.

我们的起重机钢丝绳是先进冶金技术的巅峰之作, 精密制造, 和严格的测试. 他们被设计成最强的, 最耐用, 以及起重系统中最安全的连接, 确保在最具挑战性的环境中发挥最佳性能.

1. 不妥协的实力 & 耐用性:

由各种等级的高碳钢制成 (例如, IPS, 电子工业园区, EEIP), 我们的绳索具有卓越的抗拉强度. 这意味着更高的安全系数, 更强的抗断裂能力, 以及充满信心地处理最大工作量的能力.

2. 增强抗疲劳性:

滑轮和卷筒的持续弯曲是钢丝绳故障的主要原因. 我们的绳索采用最佳芯结构和精确的绳股图案设计,可承受数百万次弯曲循环, 显着延长使用寿命并减少停机时间.

3. 卓越的耐磨性:

我们提供一系列表面处理, 包括布莱特 (无涂层), 镀锌, 和不锈钢, 对抗磨损和腐蚀. 适用于最恶劣的条件, 我们的浸塑钢丝绳 (PVC或尼龙) 涂层提供额外的防磨损保护层, 水分, 和化学品暴露.

4. 卓越的抗压强度:

坚固的核心——无论是独立钢丝绳核心 (世界水利委员会) 或纤芯 (FC)——至关重要. 我们的 IWRC 结构可提供卓越的支撑,抵抗滚筒上的高负载和破碎力, 而我们的 FC 提供出色的灵活性和缓冲性.

5. 为您的应用定制:

没有两部电梯是相同的. 我们提供各种结构 (例如, 6×19, 6×36, 6x25FW, 8×19) 以满足您的特定需求:

6×19级: 适用于一般起重机服务的多功能主力, 吊装, 并拖动.

6×36级: 提供更多电线以实现更大的灵活性, 非常适合需要频繁假脱机的应用.

抗旋转: 多层结构旨在防止负载下旋转, 对于单线来说必不可少, 自由悬挂式升降机.

| 成绩 | IPS (1770 牛/平方毫米), 电子工业园区 (1960 牛/平方毫米), EEIP (2160 牛/平方毫米) |

| 核心 | 独立钢丝绳芯 (世界水利委员会), 纤芯 (FC), 合成芯 (SC) |

| 建筑 | 6x19S, 6x25FW, 6x36WS, 6x41WS, 8x19S, 和抗旋转类型. |

| 涂料 | 明亮的 (无涂层的), 镀锌 (镀锌), PVC/尼龙涂层, 不锈钢. |

| 润滑 | 在制造过程中浸渍高性能润滑剂,以减少内部摩擦并防止腐蚀. |

我们的起重机钢丝绳受到众多领域的信赖:

OSHA 和 ASME B30.2 等安全标准的总体原则是: 当有扭曲迹象时,必须停止使用钢丝绳, 过度磨损, 腐蚀, 或可能导致强度或功能完整性明显丧失的损坏.

在实践中, 这是由常规决定的, 记录检查. 检查主要有两类:

选择合适的钢丝绳至关重要. 我们的技术团队随时准备帮助您选择适合起重机负载能力的完美绳索, 占空比, 和环境条件.

请立即联系我们进行咨询和报价.

我们重视您的反馈! 请填写下面的表格,以便我们根据您的具体需求定制我们的服务.

最新评论