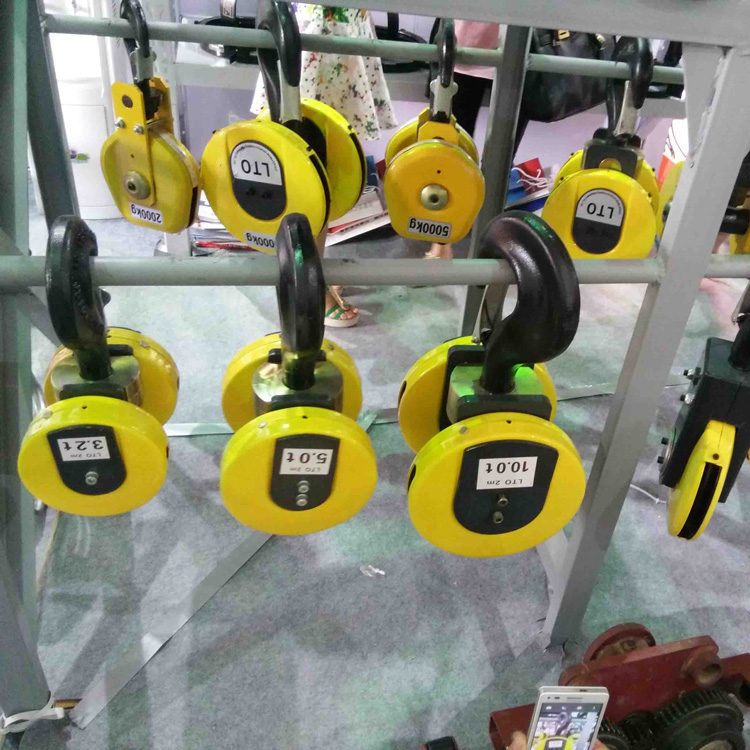

Preventing bridge crane hook wear is key to ensuring equipment safety and extending service life. The following are three systematic prevention methods, combining technical specifications and practical experience:

1. Attaching sleeves to individual wire ropes: Take a steel pipe with a diameter slightly larger than the steel wire rope, make it the same shape as the steel wire rope, and then put it on. This prevents the wire rope from rubbing against the hook, thus protecting the 起重机钩. The material of the casing can be plastic pipe, high-pressure hose or other materials.

2. Use other materials instead of wire ropes: Using nylon ropes or nylon lifting straps instead of steel wire ropes can also reduce wear on the hooks. If a wire rope is used, the length must comply with the use of the hook. Otherwise, if the wire rope is too long, the hook will be hung too high, making it difficult for the operator to see clearly; if the wire rope is too short, it will be difficult to hook, and the hooker may be easily injured. Usually, the length of the wire rope can also be determined according to the height of the operator.

3. One wire rope to lock the hook becomes three: Use rope clamps on both sides of a steel wire rope to secure it, so that it can be changed from one to three steel wire ropes and the hooks are also in contact. In this way, the friction between the wire rope and the hook can be reduced and the service life of the hook and rope can be increased.

Visual inspection

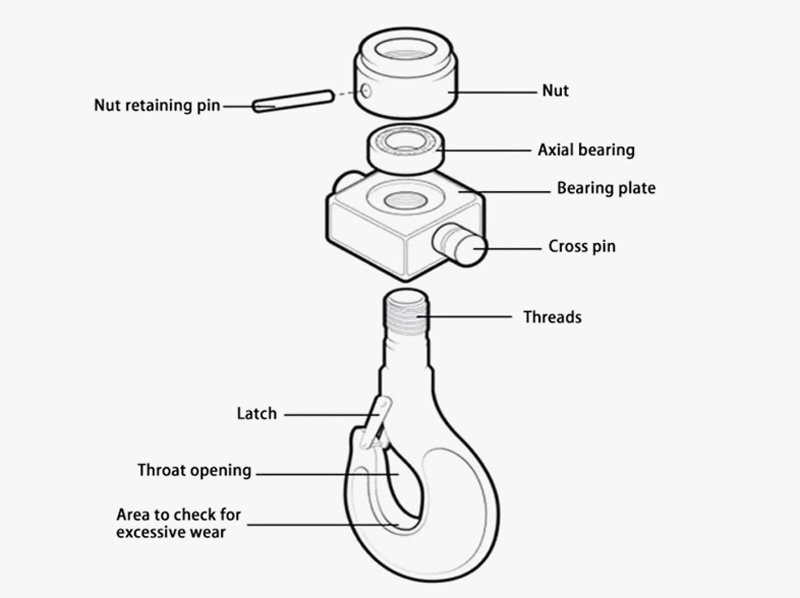

频率: Check the hook surface for cracks, deformation or rust before each shift.

Key areas: hook mouth, threaded connection, bearing contact surface.

工具: Use a magnifying glass or endoscope to detect small cracks.

方面

Hook mouth wear amount: If it exceeds 10% 原来的尺寸, it must be scrapped (refer to GB/T 10051.1 标准).

Thread wear: If the pitch deviation is >5%, the nut needs to be replaced or the thread repaired.

无损检测 (NDT)

Magnetic particle inspection: once every 6 月份, if any surface cracks are found, 立即停止使用.

Ultrasonic testing: Detecting internal defects for high-load hooks.

Overload prohibited

安全系数: The rated load of the hook must be ≥ the requirements of the crane’s working level (such as the safety factor of A5-class crane ≥ 4:1).

Dynamic load control: avoid emergency stops and starts, and control acceleration within 0.1~0.3m/s².

Avoid diagonal pulling and hanging

Deflection angle limit: The angle between the sling and the vertical direction is ≤45° to prevent unilateral wear of the hook mouth.

案件: In a steel plant, the local wear of the hook mouth exceeded the standard by 30% due to cable pulling, causing a decoupling accident.

Anti-rotation measures

Install anti-rotation bearing: reduce the rotation friction of the 起重机钩 and extend the life of the hook body.

Use anti-rotation wire rope: such as 35W×K7 structural wire rope.

Lubrication solution

Lubrication points: hook neck bearing, threaded connection, 滑轮组.

Grease selection: Use lithium-based grease in high-temperature environments (dropping point ≥ 180°C), and use calcium-based grease in humid environments.

Period: Lubricate every 200 工作时间, shortened to 100 hours under heavy load conditions.

Surface anti-corrosion treatment

Coating process: hot-dip zinc (thickness ≥ 80 μm) or Dacromet coating (salt spray resistance ≥ 1000h).

Daily protection: Clean acid and alkali residues after work and spray WD-40 anti-rust agent.

Material upgrade

高强度合金钢: 34CRMO (tensile strength ≥1080MPa) is used to replace ordinary carbon steel.

Process improvement: 锻造 + 淬火和回火治疗, hardness control HRC 38-42.

Anti-wear design

Hook mouth liner: Install nylon or polyurethane sheath (thickness ≥5mm) to reduce friction between metals.

Replaceable hook tip: Modular design, only replace the worn parts instead of the entire hook.

物联网 (IoT) 传感器

Real-time monitoring: Install strain gauges and acceleration sensors to monitor load distribution and vibration frequency.

Early warning threshold: Wear rate >0.1mm/month triggers system alarm.

AI image recognition

Automatic detection: identify surface defects through camera + deep learning algorithm (accuracy rate >95%).

案件: After a port crane adopted this system, the maintenance response time was shortened by 70%.

Through the combination of the above technology and management, the wear rate of the bridge crane hook can be effectively reduced by 50% 到 80%, while complying with international standards such as ISO 4309 和fem 9.511. It is recommended that enterprises establish a preventive maintenance system and incorporate it into the equipment life cycle management system.

我们重视您的反馈! 请填写下面的表格,以便我们根据您的具体需求定制我们的服务.

最新评论