桥式起重机是制造工厂的主力, 建筑工地, 和仓库, 在提升和移动重物方面发挥着至关重要的作用. 然而, 它们的安全和高效运行在很大程度上依赖于定期和彻底的检查. 忽视检查可能导致设备故障, 工作场所事故, 以及代价高昂的停机时间. 在这个博客中, 我们将引导您逐步了解如何正确检查桥式起重机.

检查前准备

开始检查前, 适当的准备对于确保过程安全有效至关重要.

- 1. 审核文档: 收集起重机的操作手册, 维修记录, 以及之前的检查报告. 这有助于您了解起重机的历史, 任何过去的问题, 及具体检验要求.

- 2. 准备工具和设备: 配备必要的工具,例如手电筒, 卷尺, 扭矩扳手, 检查镜, 以及用于记录发现的相机. 还, 确保您拥有个人防护装备 (PPE) 像一顶安全帽, 安全鞋, 手套, 如果在高处工作,则需携带安全带.

- 3. 确保该区域安全: 封锁起重机周围区域以防止未经授权的访问. 设置警告标志并确保检查期间没有人在起重机下工作或行走.

- 4. 检查电源: 确保起重机电源已关闭并上锁/挂牌 (心) 以避免检查过程中意外启动.

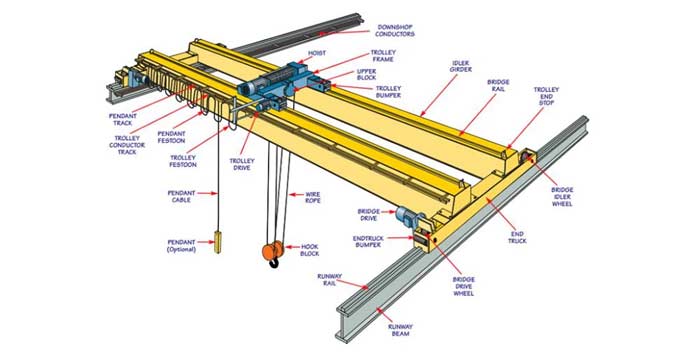

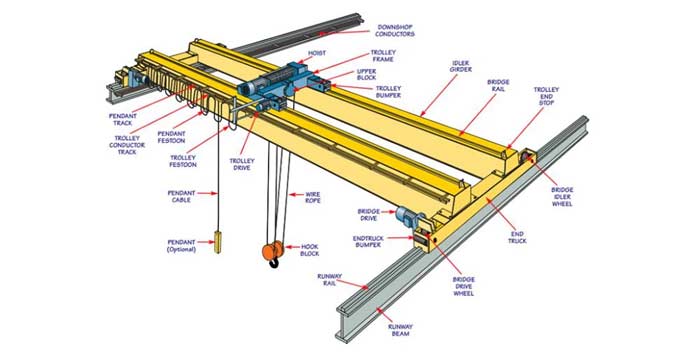

关键部件的目视检查

详细的目视检查是起重机检查的基础. 重点关注以下关键组件:

1. 提升系统

提升系统

- 桥式起重机吊钩: 检查裂缝, 形变, 钩喉或钩柄上的磨损, 以及闩锁损坏. 确保吊钩可自由旋转且闩锁功能正常,以防止负载滑动.

- 钢丝绳: 检查断线, 纠结, 腐蚀, 穿, 以及润滑不当. 注意滚筒和滑轮附近磨损较常见的区域. 测量绳索直径以检查是否过度磨损 - 是否低于制造商建议的限值, 更换绳子.

- 滚筒和滑轮: 寻找裂缝, 卷筒法兰或滑轮槽磨损, 和错位. 确保 起重机钢丝绳卷筒 没有损坏,绳索正确固定在凹槽中,没有重叠.

- 刹车系统: 检查刹车片是否磨损, 适当调整, 和污染 (油或灰尘). 测试制动器操作以确保其能够牢固地保持额定负载.

2. 桥和电车

手推车

- 桥梁大梁: 检查桥梁是否有裂缝, 弯曲, 或扭曲. 检查大梁和端部卡车之间的连接是否紧固和磨损迹象.

- 手推车: 检查手推车车轮是否磨损, 裂缝, 并正确对齐. 检查小车驱动机构, 包括齿轮和轴承, 是否有异常噪音或损坏.

- 跑道导轨: 检查跑道导轨的直线度, 水平度, 并佩戴. 寻找松动的紧固件, 损坏的钢轨接头, 轨道上的碎片可能会干扰起重机的移动.

3. 电气系统

起重机无线电控制

- 电缆电线: 检查电缆是否磨损, 连接松动, 和损坏的绝缘层. 确保电缆得到适当支撑,并且不会拖拉或摩擦其他组件.

- 控制面板: 检查控制面板是否有过热迹象, 腐蚀, 或水损坏. 测试按钮, 开关, 和指标以确保其正常运行.

- 限位开关: 验证提升机上、下限位开关的操作情况, 以及桥和小车的行程限位开关. 这些开关可防止起重机移动超出安全限制.

操作测试

目视检查后, 进行操作测试以确保起重机在负载下正常运行 (如果适用) 和空载条件.

- 1. 空载测试: 打开电源并测试葫芦, 桥, 以及小车在各个方向上的移动. 检查运行是否顺畅, 不寻常的噪音, 以及适当的制动. 确保当起重机达到安全极限时限位开关激活.

- 2. 负载测试: 使用测试负载进行负载测试 100% 到 125% 起重机的额定起重量 (遵循制造商指南). 缓慢提升负载, 水平移动它, 并降低它. 观察桥梁是否有过度偏转, 组件发出异常噪音, 或者刹车系统有问题. 确保负载在整个测试过程中保持稳定.

- 3. 测试后检查: 完成操作测试后, 关闭电源并对关键部件进行最终目视检查,以确保测试期间不会出现新问题. 检查是否有任何松动的紧固件或可能出现的应力迹象.

文档和后续行动

完整的文件记录和及时的跟进对于维护起重机的安全记录和及时解决问题是必不可少的. 跳过此步骤可能会导致被忽视的问题升级为重大危险.

- 1. 记录检验详情: 记录检查的各个方面, 包括日期, 检查员姓名, 起重机识别号, 以及已检查组件的完整列表. 对于每个组件, 注意它的状况——是否状况良好, 有轻微磨损, 或有严重缺陷. 附上有问题区域的照片或视频以提供视觉证据.

- 2. 按严重程度对缺陷进行分类: 对缺陷进行分类以确定修复的优先顺序: - 批判的: 造成直接危险的缺陷 (例如, 裂钩, 断钢丝绳). 起重机必须立即停止使用,直到维修完成并得到验证. - 主要的: 很快可能变得至关重要的问题 (例如, 磨损的刹车片低于推荐厚度). 在短时间内安排维修, 并在必要时限制起重机的使用. - 次要的: 不影响安全的外观损坏或轻微磨损 (例如, 轻微油漆剥落). 在日常维护中解决这些问题.

- 3. 更新维护日志: 将检查报告整合到起重机的官方维护日志中. 该日志应跟踪所有检查, 维修, 替换, 和润滑计划. 它可以作为未来检查的历史记录,并帮助识别重复出现的问题.

- 4. 沟通并分配行动: 与相关利益相关者分享检查报告, 包括维护团队, 督导员, 和起重机操作员. 分配明确的修复缺陷的责任——指定谁来完成这项工作, 什么时候完成, 以及如何验证. 跟进以确保所有行动按计划进行.

桥式起重机需要多久检查一次?

桥式起重机检查的频率取决于使用情况, 环境, 和监管要求. 以下是一般准则:

- 1. 日常检查: 由操作员在每班前进行. 检查是否存在明显问题,例如损坏的挂钩, 松动的电缆, 或启动时有异常声音.

- 2. 月度/季度检查: 由维护人员执行. 包括更详细的目视检查和基本操作测试.

- 3. 年度检查: 由合格检查员进行全面检查 (经相关机构认证). 这包括负载测试, 详细的元件测量, 和电气系统诊断.

- 4. 重大维修或事故后: 进行任何重大维修后彻底检查起重机, 修改, 或事件 (例如, 超载, 碰撞) 确保操作安全.

结论

检查桥式起重机是一个系统化的过程,结合了准备工作, 目视检查, 操作测试, 文档, 和后续行动. 遵守本指南, 您不仅遵守安全法规,还可以保护您的员工免受事故的影响并延长起重机的使用寿命. 记住, 安全永远不应受到损害——定期检查是防止代价高昂的停机和悲剧事件的一项投资. 如果您对检查的任何方面不确定, 请咨询合格的起重机检验员或制造商以获得指导.

关于桥式起重机检查清单的常见问题解答

Q1: 桥式起重机检查清单中通常包括哪些关键部分?

A: 标准清单涵盖检查前的准备工作 (文件审查, 工具/个人防护装备准备, 区域安全, 心), 关键部件的目视检查 (提升系统, 桥/电车, 电气系统), 操作测试 (空载, 加载, 测试后检查), 和文件/后续行动 (记录调查结果, 缺陷分类, 维护日志更新).

Q2: 日常检查与日常检查频率有何不同. 清单中的年度检查?

A: 日常检查 (由运营商) 关注明显的问题,例如损坏的钩子, 松动的电缆, 或启动噪音. 年度检查 (由合格的检查员) 很全面, 包括负载测试 (100%-125% 额定容量), 详细的元件测量, 和电气诊断——在大多数检查表中两者都是强制性的,以涵盖短期和长期安全.

Q3: 谁负责填写桥式起重机检查清单?

A: 每日检查表由起重机操作员在每次轮班前完成. 月度/季度检查表由维护人员处理. 年度和维修后检查表必须由经过认证的合格检查员填写 (根据 OSHA 或当地监管标准) 确保合规.

Q4: 为什么缺陷分类在检查清单中很重要?

A: 缺陷分类 (批判的, 主要的, 次要的) 清单中有助于确定行动的优先顺序. 严重缺陷 (例如, 钩子破裂) 需要立即关闭; 主要问题 (例如, 磨损的刹车片) 需要及时维修; 次要的 (例如, 油漆剥落) 前往日常维护. 这可以防止被忽视的危险并简化维修工作流程.

Q5: 是否可以针对不同类型的桥式起重机定制检查表?

A: 是的. 虽然核心部分是通用的, 检查表应根据起重机类型定制 (例如, 桥式起重机, 龙门起重机) 及使用场景 (重型 vs. 轻型). 例如, 港口龙门起重机的检查表可能会增加对耐候部件的额外检查, 而仓库桥式起重机可能会强调跑道轨道的对齐.

最新评论