起重機掛鉤檢查中包含的內容?

2025-09-08

The crane hook is a deceptively simple piece of equipment. 這是決賽, critical link between your crane and the load it carries. A failure here isn’t just an equipment malfunction; it’s a catastrophic safety incident waiting to happen. This is why a rigorous and systematic inspection regimen for your crane hooks is not just a recommendation—it’s an absolute necessity.

A proper crane hook inspection is a multi-layered process, ranging from daily visual checks to periodic detailed examinations. Understanding what to look for can prevent accidents, ensure compliance with OSHA and ASME standards, and save your company from costly downtime and liability.

The Three Levels of Crane Hook Inspection

Inspection frequency and depth are typically broken down into three levels, as guided by standards like ASME B30.10 (掛鉤).

1. Frequent (Daily/Pre-Use) 目視檢查

This is the check performed by the crane operator or rigger before each shift or use. It’s a quick visual assessment to identify any obvious signs of damage or wear.

尋找什麼:

- 1. 扭轉或彎曲: Is the hook twisted or bent from its original shape? A twisted hook is under immense stress and is significantly weaker.

- 2. Cracks or Nicks: Visually check for any obvious cracks, especially in high-stress areas like the saddle (inside curve of the hook) or the shank/eye.

- 3. 穿: Check the saddle or throat opening for wear. A rule of thumb is that if the throat opening has increased by more than 15%, or the hook has lost more than 10% 其原始尺寸, it must be taken out of service.

- 4. Latch Mechanism: 如果配備了, does the safety latch function correctly? Is it broken, 彎曲, or missing? A faulty latch can allow a sling or chain to accidentally disengage.

- 5. Rigging Damage: Check that the load-bearing surfaces are not damaged by the rigging (例如。, deep grooves caused by wire ropes or chains).

2. 定期 (每月/每季度) 檢查

This is a more detailed inspection, often performed by a designated competent person or maintenance supervisor. It includes everything in the frequent inspection but is more thorough.

尋找什麼:

- 1. Measurement of Wear: Use calipers to accurately measure the hook’s throat opening and compare it to the manufacturer’s original specifications. Document this for tracking over time.

- 2. 形變: Look for any signs of plastic deformation (拉伸). A hook that has been overloaded may not return to its original shape.

- 3. Corrosion and Pitting: Significant corrosion can reduce the hook’s cross-section and strength. Deep pitting can act as a stress concentrator, leading to crack formation.

- 4. 旋轉機構: For swivel hooks, check that the hook rotates freely without binding. Inspect the bearings for wear and play.

- 5. Latch Function: Test the latch spring tension and ensure it closes and operates smoothly.

3. 定期 (年度的) Thorough Inspection

This is a comprehensive inspection that must be performed by a certified crane inspector or a competent person following a detailed written procedure. It often requires cleaning the hook and may involve Non-Destructive Testing (無損檢測).

What is included:

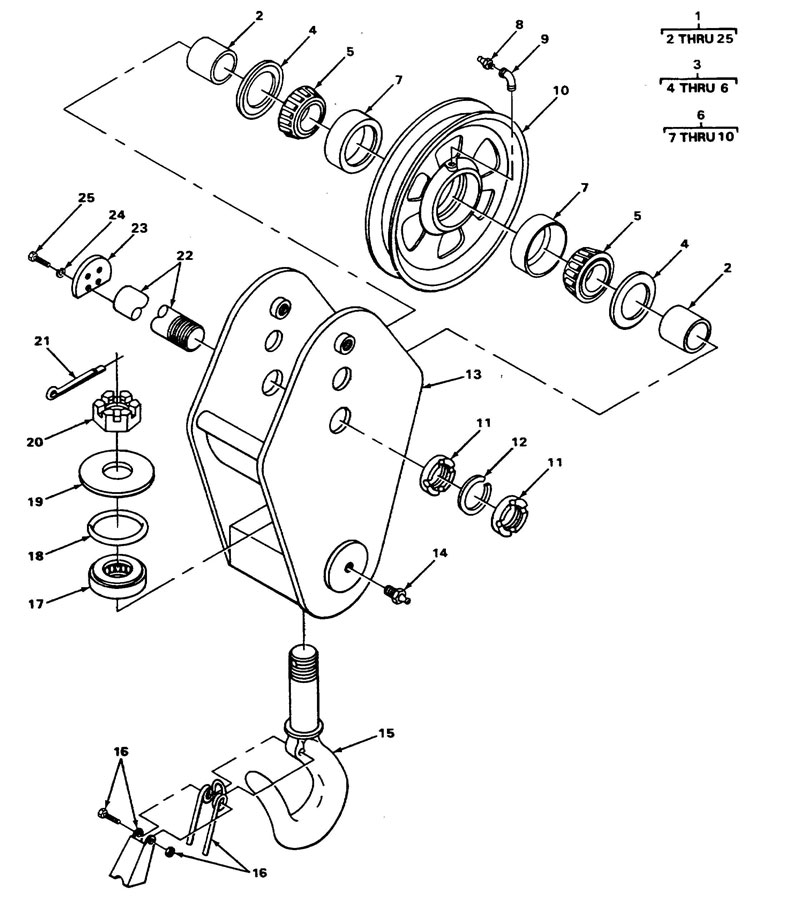

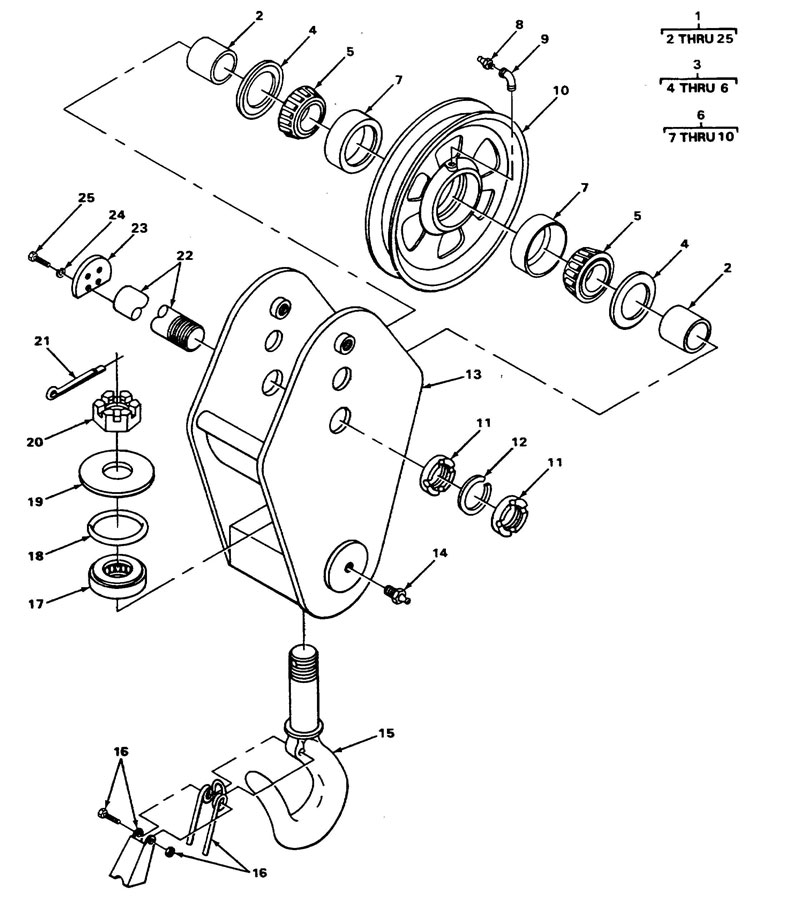

- 1. Complete Disassembly and Cleaning: 鉤子, 閂鎖, and swivel mechanism (如果適用的話) are disassembled, cleaned of all dirt and grease, and inspected part-by-part.

- 2. 無損檢測 (無損檢測): This is the most critical step for finding hidden flaws. The hook is typically inspected using:

- 磁粉探傷 (MPI): Excellent for finding surface and near-surface cracks on ferromagnetic materials.

- 染料滲透探傷 (深度PI): Used for finding surface cracks on any non-porous material.

- 3. Dimensional Accuracy: A full dimensional check is performed to ensure the hook has not deformed beyond allowable limits.

- 4. Detailed Documentation: A formal report is generated, detailing the inspection methods, 進行的測量, and the overall condition of the hook. This is a vital legal and safety record.

Common Hook Defects and Rejection Criteria

Any hook exhibiting the following defects must be immediately REMOVED FROM SERVICE and repaired or replaced by a qualified technician. Never attempt to repair a hook by welding, straightening, or bending.

- 1. 裂縫: 任何裂紋, anywhere, of any size.

- 2. 過度磨損: >15% increase in throat opening or >10% reduction of original material.

- 3. 形變: 任何彎曲, 扭曲, or stretching from the original shape.

- 4. Thread Damage: Damaged or worn threads on the hook nut or collar.

- 5. 腐蝕: Significant corrosion that reduces the structural integrity.

- 6. Missing or Defective Latch: A latch that is broken, malfunctioning, or missing.

Proactive Maintenance Tips

- 1. Keep it Clean: Wipe down hooks regularly to remove abrasive dirt and grime.

- 2. Lubricate: Periodically lubricate the swivel mechanism and latch pivot points according to the manufacturer’s instructions.

- 3. 培訓你的團隊: Ensure all operators and riggers are trained to perform pre-use inspections and recognize the signs of a defective hook.

- 4. Keep Records: Meticulously log all inspection results. This history is crucial for identifying wear patterns and proving compliance.

A crane hook inspection is a systematic process designed to catch small problems before they become big failures. It blends simple visual checks with advanced technical methods. By integrating daily vigilance, periodic measurements, and annual certified inspections into your maintenance program, you protect your most valuable assets: 你的人, your equipment, and your worksite.

Never take that humble hook for granted. Its integrity is the foundation of your lifting safety.

最新評論