在鐵路維護和建設領域, 聚光燈常常落在大型起重機本身上——它們令人印象深刻的伸展範圍, 強大的引擎, 和龐大的規模. 但任何經驗豐富的操作員或工程師都會告訴您,最關鍵的, 也是最容易被忽視的, 組件是不起眼的起重機吊鉤. 它是機器和多噸負載之間的單點接觸, 使其規格不僅僅是效率問題, 但絕對安全.

了解鐵路起重機吊鉤規格對於確保安全操作至關重要, 防止災難性故障, 並遵守嚴格的行業法規. 讓我們詳細分析一下您需要了解的關鍵規格.

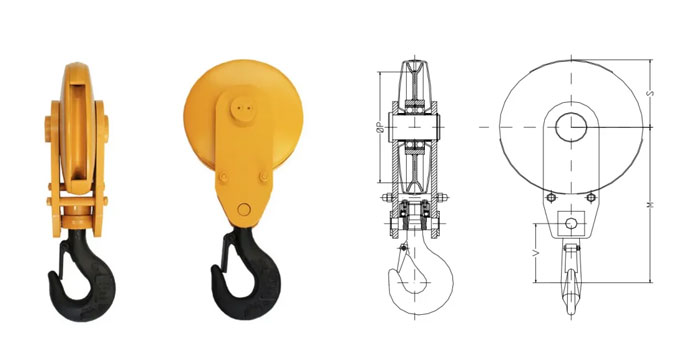

鐵路起重機雙鉤

這是最基本的規格. 它定義了吊鉤設計可安全提升的最大重量.

吊鉤的設計必須符合其在鐵路上的預期應用.

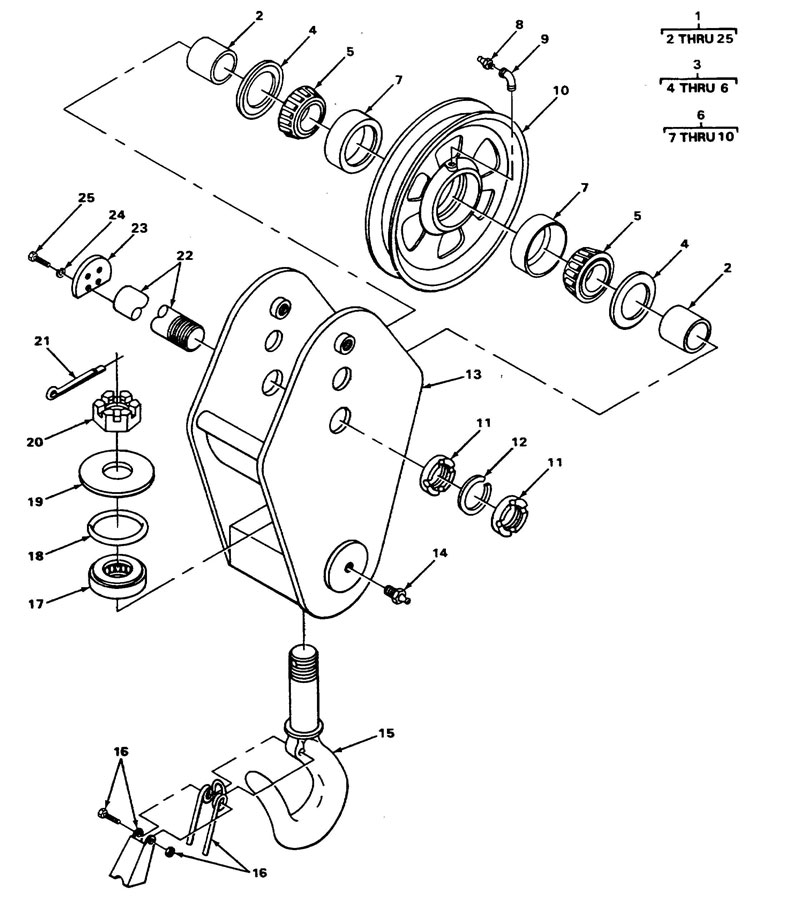

刀柄類型: 最常見的設計是 U 形鉤, 它通過U形銷和卸扣連接到起重機的起重繩上. 這樣可以輕鬆旋轉和更換.

喉嚨打開: 吊鉤喉部的大小決定了吊索的尺寸, 鐐銬, 和其他可以使用的索具硬件. 處理大型物體需要更大的喉部, 橋樑或預製軌道段等大件物品.

積分 & 閂鎖:

鐵路起重機旋轉吊鉤

鐵路鉤承受極大的壓力, 疲勞, 和環境條件.

材料: 它們通常由高級材料鍛造而成, 熱處理合金鋼 (例如。, 美國鋼鐵協會 4140). 鍛造使金屬的晶粒結構與鉤子的形狀一致, 與鑄造相比具有卓越的強度和韌性.

結束: 耐用的表面處理, 例如電鍍鋅或堅固的塗漆塗層, 對於防止雨水腐蝕至關重要, 雪, 和碎片——鐵路環境中的共同敵人.

遵守公認的標準是不容談判的. 信譽良好的製造商設計和測試掛鉤以滿足組織的嚴格規範,例如:

ASME B30.10: 美國機械工程師協會標準專門涵蓋“掛鉤”。

OSHA: 職業安全與健康管理局法規規定了檢查和使用要求.

EN標準: 在歐洲, 掛鉤必須符合 EN 等標準 1677-1.

認證: 掛鉤應附有合格證書, 通常可追溯到唯一的序列號, 證明他們符合要求的標準.

合適的鐵路起重機吊鉤上會清楚地標明其重要統計數據. 尋找:

額定負載 (wll)

製造商名稱或徽標

唯一序列號

牌號或材料類型

這些標記對於保存記錄至關重要, 可追溯性, 以及日常操作前檢查.

選擇正確的魚鉤並不是要找到“合適”的魚鉤。這是為了將吊鉤的規格與起重機的能力以及鐵路作業的具體要求精心匹配.

永遠記住:

鐵路起重機吊鉤是工程簡單性和強度的傑作. 尊重其規格, 您確保它仍然可靠, 讓您的運營順利進行的無名英雄, 最重要的是, 安全地.

我們重視您的反饋! 請填寫下面的表格,以便我們可以根據您的特定需求來量身定制服務.

最新評論