橋式起重機是工業環境中廣泛使用的不可或缺的重型起重設備, 倉庫, 建築工地, 和製造工廠. 它們在簡化物料搬運流程方面發揮著至關重要的作用, 提高工作效率, 並確保重物的安全移動. 全面了解企業的運作機制 橋式起重機, 熟悉其關鍵部件及其各自的功能非常重要. 本文全面概述了橋式起重機的主要組件以及它們如何協同工作以提供可靠的起重性能.

橋式起重機由哪幾部分組成?

1. 主梁 (橋樑大樑)

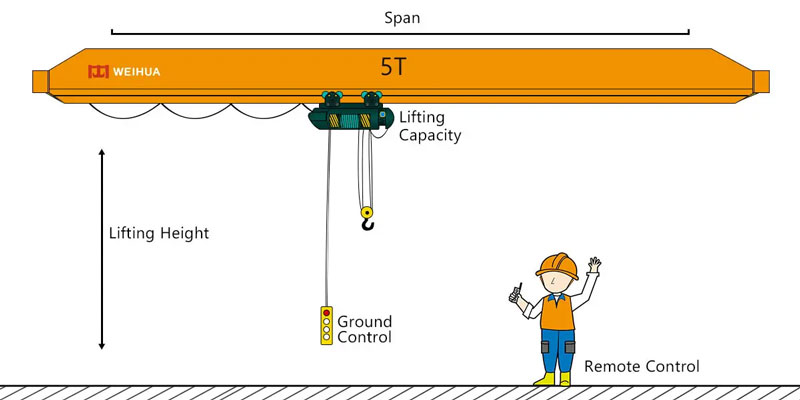

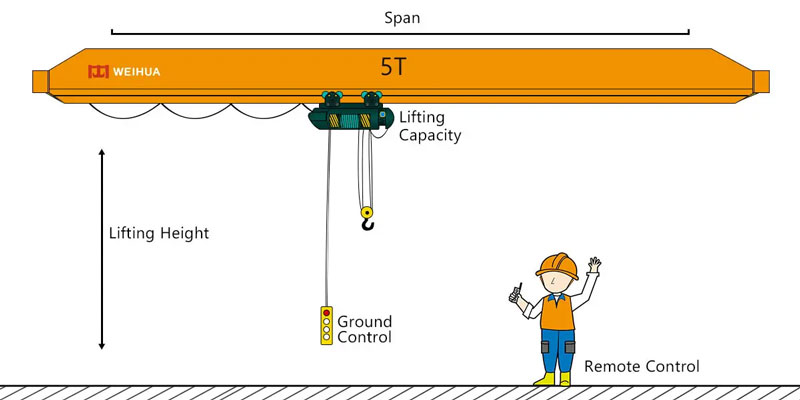

主梁, 也稱為橋樑, 是橋式起重機的主要承重結構. 它跨越工作空間的寬度, 連接兩端卡車. 通常由高強度鋼製成, 主梁設計用於承受提升負載的重量, 起重機自身重量, 以及運行過程中的各種動態力. 其堅固的結構確保了穩定性和剛性, 防止承載重物時過度偏轉. 主梁還充當小車的軌道, 允許其沿著樑的長度水平移動.

2. 端梁裝置 (末端車廂)

端梁裝置位於主梁兩端. 每個末端卡車均由輪子組成, 車軸, 軸承, 和驅動機構. 車輪沿著安裝在建築物柱子或高架結構上的起重機跑道軌道行駛, 使整個起重機能夠縱向移動 (沿著跑道的長度). 末端卡車的驅動機構可以是電動或手動的, 取決於起重機的設計和應用要求. 高品質的末端卡車確保起重機的平穩和精確的移動, 減少摩擦和磨損,實現長期可靠運行.

3. 手推車

小車是沿主梁軌道運行的可移動裝置. 它承載起昇機構,負責在起重機跨度的寬度上水平移動負載. 類似於 末端卡車, 手推車配有輪子, 驅動系統, 和製動系統. 驅動系統為小車的運動提供動力, 使其能夠將負載精確地定位在所需位置上方. 制動系統確保手推車在需要時安全停止, 防止裝卸過程中意外移動.

4. 起昇機構

起昇機構是負責提升和下降負載的核心部件. 它包括一個電動機, 變速箱, 一個

起重機鋼絲繩捲筒, 一個

起重機鋼絲繩 或鏈, 和一個鉤塊. 電動機提供動力, 傳輸到變速箱以調節速度. 然後變速箱帶動滾筒旋轉, 纏繞或鬆開鋼絲繩或鏈條. 當滾筒旋轉時, 這

鉤塊 連接到鋼絲繩或鏈條的末端向上或向下移動, 提升或降低負載. 起昇機構設有限位開關等安全裝置,防止超載、超程, 確保安全運行.

5. 控制系統

控制系統是橋式起重機的“大腦”, 管理其所有活動和運營. 它包括一個控制面板 (任一吊墜控制, 遙控, 或駕駛室控制), 變頻器, 和一個PLC (可編程邏輯控制器). 操作員使用控制面板發出提升等命令, 降低, 小車運動, 和起重機行程. 變頻器調節電機的速度, 確保平滑加減速以避免負載搖擺. PLC處理來自控制面板的輸入信號並協調各部件的操作, 提高起重機的精度, 效率, 和安全.

6. 安全裝置

安全是橋式起重機操作的重中之重, 起重機中集成了一系列安全裝置,以防止發生事故. 常見的安全裝置包括:

- 1. 過載限制器: 檢測負載重量,如果負載超過起重機的額定起重量,則停止起重作業, 保護起重機並防止結構損壞.

- 2. 限位開關: 包括起昇機構的上下限位開關,以防止吊鉤組超程, 以及小車和起重機行程的限位開關,將其運動限制在指定範圍內.

- 3. 緊急停止按鈕: 允許操作員在緊急情況下立即停止所有起重機操作, 確保人員和設備安全.

- 4. 防撞裝置: 通過檢測起重機之間的距離並在距離太近時觸發警報或停止起重機,防止在同一跑道上運行的多台起重機之間發生碰撞.

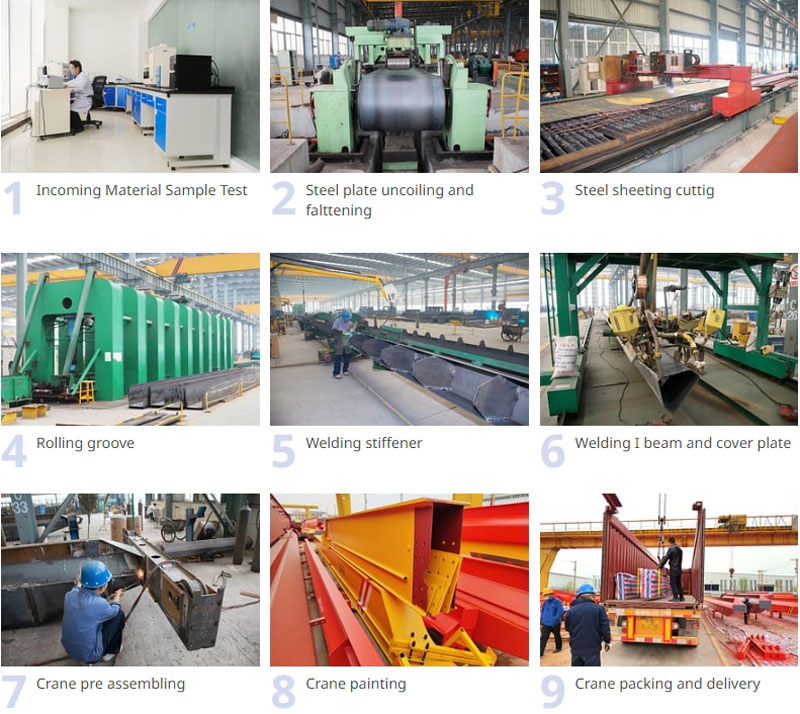

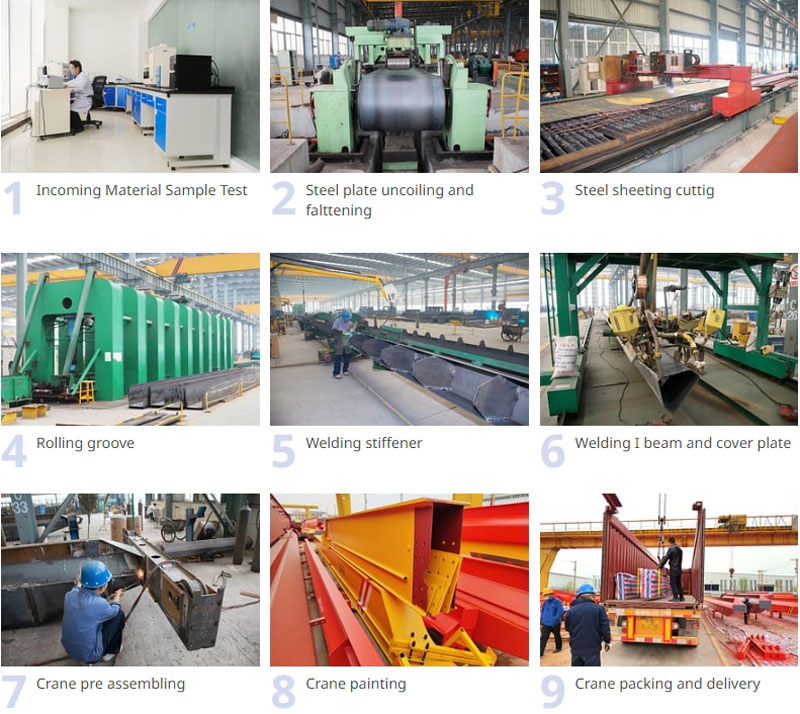

橋式起重機製造工藝

橋式起重機應用領域

橋式起重機因其多功能的起重能力而被廣泛應用於各個行業. 一些關鍵應用領域包括:

- 1. 製造業: 用於提升和移動原材料, 半成品, 以及生產機械的工廠的成品, 汽車, 電子產品, 和電器.

- 2. 倉儲物流: 方便裝載, 卸貨, 以及倉庫內貨物的堆放, 配送中心, 和端口, 提高倉儲和運輸效率.

- 3. 冶金行業: 處理鋼錠等重金屬材料, 線圈, 以及鋼廠和鑄造廠的鑄件, 在高溫和惡劣環境下運行.

- 4. 建築業: 用於建築工地提升建築材料, 裝置, 和組件, 協助建造建築物, 橋樑, 和其他結構.

我們的橋式起重機的優勢

我們的橋式起重機的設計和製造注重質量, 表現, 和安全. 主要優勢包括:

- 1. 高品質材料和精密製造確保即使在苛刻的工業環境下也能實現較長的使用壽命和可靠的運行.

- 2. 先進的控制系統和安全裝置提供精確的負載定位和全面的事故預防, 最大限度地降低運營風險.

- 3. 可定制設計,滿足不同行業的具體要求, 包括各種負載能力, 跨度長度, 和起升高度.

- 4. 高效能源消耗和低維護成本, 減少客戶的總體運營費用.

綜上所述, 了解橋式起重機的部件和功能對於選擇正確的設備至關重要, 確保安全運行, 並最大限度地發揮其性能. 我們的橋式起重機結合了先進技術, 卓越品質, 和全面的安全功能,為各種工業應用提供高效可靠的物料搬運解決方案. 如果您有任何疑問或需要定制橋式起重機解決方案, 請隨時聯繫我們.

以 PDF 形式分享: 下載

最新評論