Cầu trục dầm đôi là thiết bị xử lý vật liệu mạnh mẽ được thiết kế để nâng và vận chuyển vật nặng trong môi trường công nghiệp.

Cầu trục dầm đôi là thiết bị xử lý vật liệu mạnh mẽ được thiết kế để nâng và vận chuyển vật nặng trong môi trường công nghiệp. Được thiết kế với hai dầm chính song song, nó mang lại sự ổn định và khả năng chịu tải vượt trội so với các mẫu dầm đơn, làm cho nó trở thành lựa chọn phù hợp cho các ứng dụng hạng nặng như nhà máy thép, nhà máy sản xuất, Kho, và các công trường xây dựng. Cho dù bạn cần di chuyển máy móc, nguyên liệu thô, hoặc thành phẩm, cần cẩu dầm đôi của chúng tôi kết hợp độ chính xác, độ bền, và an toàn để tối ưu hóa quy trình làm việc của bạn.

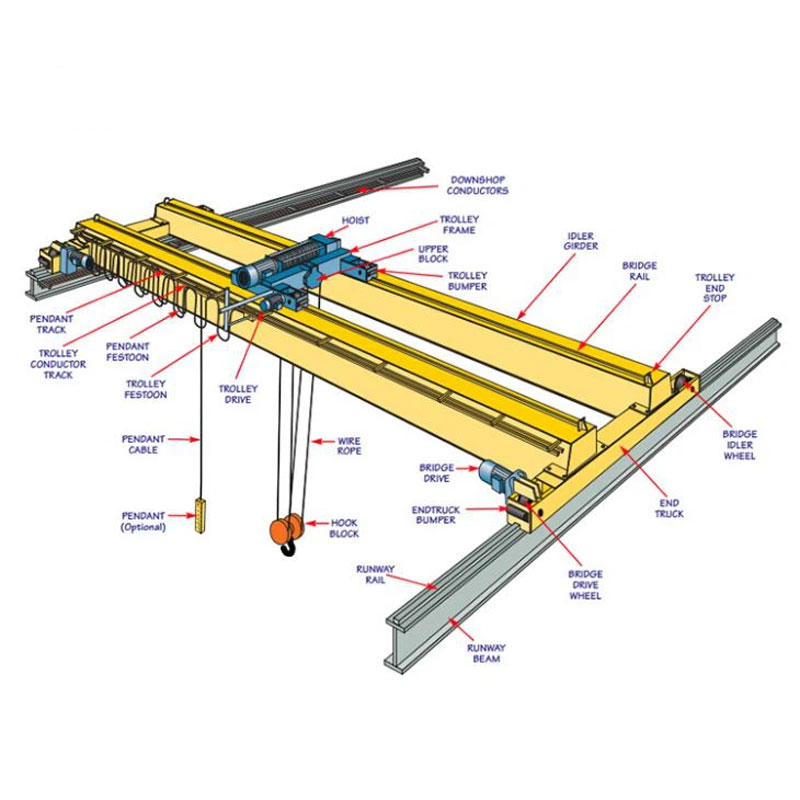

Cầu trục dầm đôi là loại cầu trục gồm có hai dầm chính nằm ngang được hỗ trợ bởi các xe tải cuối (hoặc toa cuối) chạy dọc theo đường ray trên cao (đường băng) gắn trên cột tòa nhà hoặc cấu trúc độc lập. Cơ cấu nâng của cần trục—thường là tời hoặc xe đẩy—được gắn trên một xe đẩy di chuyển dọc theo chiều dài của dầm chính, cho phép bao phủ 360° không gian làm việc bên dưới.

Không giống cần cẩu dầm đơn, dựa vào một chùm tia chính duy nhất, thiết kế dầm đôi phân bổ trọng lượng đồng đều hơn, cho phép họ xử lý tải nặng hơn nhiều (thường lên tới 500 tấn hoặc hơn). Điều này khiến chúng trở nên cần thiết cho các ngành công nghiệp đòi hỏi phải nâng vật nặng thường xuyên., nơi độ tin cậy và an toàn là không thể thương lượng.

Cần cẩu dầm đôi của chúng tôi được chế tạo để hoạt động vượt trội trong các môi trường đòi hỏi khắt khe. Dưới đây là những tính năng nổi bật của họ:

|

Tham số

|

Phạm vi/Chi tiết

|

|

Công suất nâng tối đa

|

10 tấn – 500 tấn (tùy chọn tùy chỉnh có sẵn cho tải cao hơn)

|

|

Chiều dài nhịp

|

10m – 35m (nhịp tùy chỉnh theo yêu cầu)

|

|

Nâng chiều cao

|

6m – 30m (điều chỉnh dựa trên ứng dụng)

|

|

Tốc độ nâng

|

0.5m/phút – 10m/phút (tốc độ thay đổi với tùy chọn biến tần)

|

|

Tốc độ di chuyển của xe đẩy

|

5m/phút – 30m/phút

|

|

Tốc độ di chuyển của cần cẩu

|

10m/phút – 50m/phút

|

|

Lớp lao động

|

A5 – A8 (Tiêu chuẩn ISO; thích hợp cho công việc nhẹ đến nặng, sử dụng liên tục)

|

|

Cung cấp điện

|

380V/3Ph/50Hz (có thể tùy chỉnh cho 220V/440V hoặc các khu vực khác)

|

|

Chế độ điều khiển

|

Kiểm soát mặt dây chuyền, điều khiển từ xa (không dây), hoặc điều khiển cabin

|

Cần trục dầm đôi bao gồm một số bộ phận chính phối hợp với nhau để đảm bảo nâng và di chuyển hiệu quả:

Dầm chính

Hai dầm thép song song (dầm) tạo thành cấu trúc cầu. Chúng chịu tải trọng của xe đẩy và vật liệu được nâng lên, đòi hỏi độ bền và độ cứng cao.

Xe tải cuối

Gắn ở hai đầu dầm chính, chúng chứa các bánh xe và động cơ dẫn động cần cẩu dọc theo đường ray.

Xe đẩy

Một bộ phận di động di chuyển dọc theo đỉnh hoặc đáy của dầm chính. Nó mang vận thăng và được cung cấp năng lượng bởi động cơ riêng để di chuyển theo chiều ngang.

Palăng

Cơ chế nâng, bao gồm một trống cần cẩu, dây thừng/cáp, Và Móc cần cẩu. Nó có nhiệm vụ nâng và hạ tải, với các tùy chọn cho hoạt động điện hoặc thủy lực.

Hệ thống điện

Bao gồm động cơ, bảng điều khiển, công tắc, và nối dây để cấp điện và vận hành cần trục, xe đẩy, và vận thăng.

Bộ hạn chế quá tải, công tắc giới hạn hành trình, hệ thống dừng khẩn cấp, và các thiết bị chống lắc để đảm bảo vận hành an toàn.

Q1: Sự khác biệt giữa cầu trục dầm đôi và cầu trục dầm đơn?

MỘT: Cầu trục dầm đôi có hai dầm chính, cung cấp khả năng chịu tải cao hơn (10+ tấn) và sự ổn định, làm cho chúng phù hợp cho việc sử dụng nặng. Cầu trục dầm đơn có một dầm chính, nhẹ hơn, và tốt hơn cho tải nhẹ hơn (lên đến 10 tấn) trong không gian làm việc nhỏ hơn.

Q2: Những ngành nào sử dụng cầu trục dầm đôi?

MỘT: Chúng được sử dụng rộng rãi trong các nhà máy thép, sản xuất ô tô, xưởng đóng tàu, công trường xây dựng, Kho (để xử lý pallet nặng), và nhà máy điện.

Q3: Cần bảo trì cầu trục dầm đôi bao lâu một lần?

MỘT: Kiểm tra định kỳ (kiểm tra độ mòn hàng ngày, bôi trơn) và bảo trì chuyên nghiệp (cứ sau 6–12 tháng) được khuyến khích để đảm bảo an toàn và tuổi thọ.

Q4: Cầu trục dầm đôi có thể được tùy chỉnh cho các ứng dụng cụ thể không?

MỘT: Đúng. Chúng tôi cung cấp các tùy chỉnh cho khả năng tải, nhịp, chiều cao nâng, hệ thống điều khiển, và các tài liệu đính kèm chuyên dụng (VÍ DỤ., nam châm để xử lý kim loại, gắp vật liệu số lượng lớn).

Q5: Cần trục dầm đôi có tuân thủ các tiêu chuẩn an toàn quốc tế không?

MỘT: Cần cẩu của chúng tôi đáp ứng ISO, Nữ, và tiêu chuẩn OSHA, với các tính năng an toàn tích hợp để đảm bảo tuân thủ các quy định công nghiệp toàn cầu.

Chia sẻ với PDF: Tải xuống

Chúng tôi coi trọng phản hồi của bạn! Vui lòng hoàn thành biểu mẫu bên dưới để chúng tôi có thể điều chỉnh các dịch vụ của mình theo nhu cầu cụ thể của bạn.

As a critical piece of equipment in the steel production process, ladle cranes for stee……

Khám phá thêm →

In the realm of heavy-duty material handling, 70 tons automated bridge cranes stand out……

Khám phá thêm →

Là thiết bị cốt lõi cho việc xếp dỡ container đi đầu trong ngành công nghiệp hiện đại……

Khám phá thêm →

Nhấp vào nút để nhận thông tin sản phẩm và báo giá trên WhatsApp.

Nhận báo giá

Nhận xét mới nhất