EOT dầm đôi (Du lịch trên cao bằng điện) cần cẩu là một thiết bị mạnh mẽ, hệ thống nâng trên cao được thiết kế để xử lý vật liệu nặng trong môi trường công nghiệp.

EOT dầm đôi (Du lịch trên cao bằng điện) cần cẩu là một thiết bị mạnh mẽ, hệ thống nâng trên cao được thiết kế để xử lý vật liệu nặng trong môi trường công nghiệp. Không giống cầu trục EOT dầm đơn, nó có hai dầm chính song song trải dài không gian làm việc, được hỗ trợ bởi các toa cuối di chuyển dọc theo đường băng trên cao. Cấu trúc này cho phép nó xử lý tải cao hơn đáng kể - thường từ 10 tấn đến 500 tấn trở lên—làm cho nó trở nên lý tưởng cho các nhiệm vụ nâng đòi hỏi độ chính xác cao, sự ổn định, và độ bền là rất quan trọng.

Chạy bằng động cơ điện, cầu trục EOT dầm đôi hoạt động bằng tời (gắn trên xe đẩy) di chuyển dọc theo dầm, kết hợp với việc di chuyển trên đường băng để bao phủ toàn bộ không gian làm việc. Nó được công nhận rộng rãi như một giải pháp đáng tin cậy để hợp lý hóa hoạt động trong các nhà máy, Kho, và công nghiệp nặng.

Cần cẩu EOT dầm đôi nổi bật nhờ thiết kế và hiệu suất tiên tiến, cung cấp những lợi thế sau:

|

Tham số

|

Phạm vi/Chi tiết

|

|

Khả năng tải định mức

|

10t–500t+ (có thể tùy chỉnh cho tải siêu nặng)

|

|

Chiều dài nhịp

|

10m–35m (nhịp dài hơn có sẵn với cốt thép kết cấu)

|

|

Nâng chiều cao

|

6m–30m (có thể điều chỉnh dựa trên chiều cao không gian làm việc)

|

|

Lớp lao động

|

A5–A8 (Tiêu chuẩn ISO; A8 cho các hoạt động nặng nhọc liên tục)

|

|

Tốc độ nâng

|

0.5m/phút–10m/phút (điều khiển tần số thay đổi để điều chỉnh tốc độ trơn tru)

|

|

Tốc độ di chuyển của xe đẩy

|

10m/phút–40m/phút

|

|

Tốc độ di chuyển của cần cẩu

|

20m/phút–60m/phút

|

|

Cung cấp điện

|

380V/50Hz (có thể tùy chỉnh cho điện áp 220V/60Hz hoặc các điện áp khác)

|

|

Chế độ điều khiển

|

Kiểm soát mặt dây chuyền, điều khiển từ xa không dây, hoặc điều khiển cabin

|

|

Tính năng an toàn

|

Bảo vệ quá tải, công tắc giới hạn, Điểm dừng khẩn cấp, thiết bị chống va chạm

|

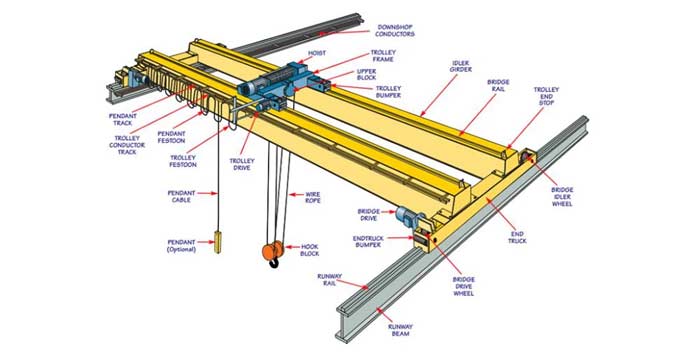

Cầu trục EOT dầm đôi bao gồm một số bộ phận chính phối hợp với nhau để đảm bảo nâng hạ đáng tin cậy:

Hai dầm thép dạng hộp hoặc dầm chữ I song song tạo thành kết cấu chịu lực chính, mở rộng không gian làm việc.

Nằm ở hai đầu dầm chính, được trang bị bánh xe di chuyển dọc theo đường ray, cho phép cần cẩu di chuyển theo chiều ngang.

Palăng (tời điện có móc, nam châm, hoặc nắm lấy) được gắn trên xe đẩy, di chuyển dọc theo dầm chính thông qua đường ray, cho phép nâng theo chiều dọc và chuyển động ngang dọc theo nhịp.

Đường ray trên cao (cài đặt trên cột hoặc tường) dẫn hướng cho toa cuối của cần cẩu, xác định phạm vi di chuyển của cần cẩu.

Bao gồm động cơ (tời, xe đẩy, du lịch cần cẩu), bảng điều khiển, cáp, và các thiết bị an toàn (cảm biến quá tải, công tắc giới hạn) để quản lý quyền lực và hoạt động.

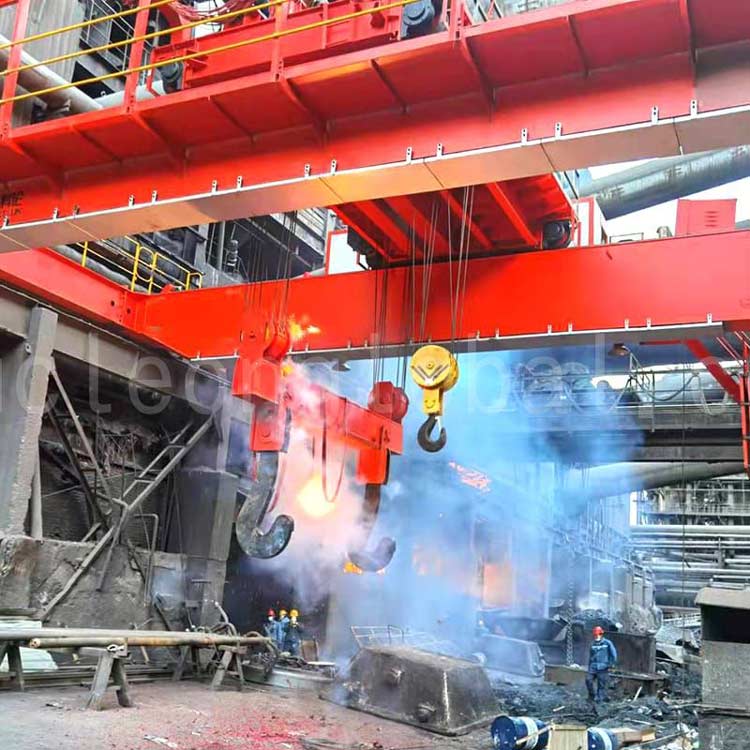

Cần cẩu EOT dầm đôi không thể thiếu trong các ngành công nghiệp đòi hỏi phải nâng vật nặng và xử lý vật liệu chính xác:

Q1: Sự khác biệt giữa cầu trục EOT dầm đôi và cầu trục dầm đơn?

MỘT: Cầu trục dầm đôi có hai dầm chính, cung cấp khả năng chịu tải cao hơn (10t+) và sự ổn định, thích hợp cho việc sử dụng nặng. Cầu trục dầm đơn có một dầm, lý tưởng cho tải nhẹ hơn (lên đến 20t) và không gian làm việc nhỏ hơn.

Q2: Cần bảo trì cầu trục EOT dầm đôi bao lâu một lần?

MỘT: Kiểm tra định kỳ (kiểm tra độ mòn hàng ngày, bôi trơn hàng tháng) và bảo trì chuyên nghiệp hàng năm được khuyến khích để đảm bảo an toàn và kéo dài tuổi thọ.

Q3: Cần cẩu EOT dầm đôi có thể được tùy chỉnh cho các môi trường đặc biệt không?

MỘT: Đúng. Các tùy chọn bao gồm thiết kế chống cháy nổ (cho khu vực nguy hiểm), lớp phủ chống ăn mòn (cho nhà máy hóa chất), và chịu nhiệt độ cao (cho các xưởng đúc).

Q4: Cầu trục EOT dầm đôi tuân thủ những tiêu chuẩn an toàn nào?

MỘT: Họ tuân thủ các tiêu chuẩn quốc tế như ISO, Nữ, TỪ, và OSHA, với các tính năng an toàn tích hợp như bảo vệ quá tải và dừng khẩn cấp.

Q5: Lắp đặt cầu trục EOT dầm đôi mất bao lâu?

MỘT: Thời gian cài đặt thay đổi tùy theo kích thước và độ phức tạp—thường là 2–4 tuần đối với mẫu tiêu chuẩn, với các mốc thời gian dài hơn cho các hệ thống tùy chỉnh hoặc có quy mô lớn.

Cho dù bạn cần nâng máy móc hạng nặng trong nhà máy hay xử lý vật liệu rời ở cảng, Cần cẩu EOT dầm đôi của chúng tôi mang lại sức mạnh, độ chính xác, và độ tin cậy để tối ưu hóa hoạt động của bạn. Liên hệ với chúng tôi để có giải pháp tùy chỉnh phù hợp với nhu cầu của bạn.

Chia sẻ với PDF: Tải xuống

Chúng tôi coi trọng phản hồi của bạn! Vui lòng hoàn thành biểu mẫu bên dưới để chúng tôi có thể điều chỉnh các dịch vụ của mình theo nhu cầu cụ thể của bạn.

20 Tôn đơn dầm vs. Cầu trục dầm đôi Sự khác biệt chính ở 20 tấn o……

Khám phá thêm →

In the realm of heavy-duty material handling, the double trolley gantry crane stands ou……

Khám phá thêm →

Là thiết bị cốt lõi cho việc xếp dỡ container đi đầu trong ngành công nghiệp hiện đại……

Khám phá thêm →

Nhấp vào nút để nhận thông tin sản phẩm và báo giá trên WhatsApp.

Nhận báo giá

Nhận xét mới nhất