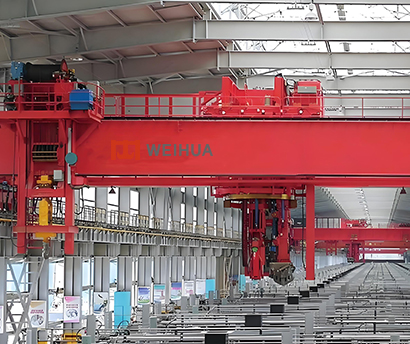

Bánh xe cần cẩu là bộ phận quan trọng tạo thành bề mặt tiếp xúc giữa cần trục hoặc tời và dầm đường băng của nó.

Bánh xe cẩu có nhiệm vụ chịu toàn bộ tải trọng của cần cẩu và các vật liệu được nâng lên, đồng thời tạo điều kiện cho việc di chuyển theo chiều dọc trơn tru và chính xác dọc theo đường băng. Được thiết kế cho độ bền và độ tin cậy cao, những bánh xe này là một phần cơ bản để đảm bảo sự an toàn, hiệu quả, và tuổi thọ của các hoạt động xử lý vật liệu của bạn. Chúng thường được gắn trên càng nâng hoặc xe tải cuối và được dẫn động bằng động cơ hoặc di chuyển tự do như bánh xe chạy không tải..

| Tham số | Đặc điểm kỹ thuật | Ghi chú |

| Đường kính bánh xe | 250mm – 800mm (10″ – 32″) | Đường kính tùy chỉnh có sẵn |

| Chiều rộng bánh xe (bước đi) | 90mm – 200mm (3.5″ – 8″) | Thay đổi theo khả năng chịu tải |

| Đường kính lỗ khoan | 60mm – 200mm (2.4″ – 8″) | Phù hợp với kích thước vòng bi tiêu chuẩn |

| Chiều cao mặt bích | 20mm – 35mm (0.8″ – 1.4″) | Tiêu chuẩn & hồ sơ tùy chỉnh |

| Lớp vật liệu | 55# Thép, 65Mn, 42CRMO, SS | Thép hợp kim 42CrMo thường dùng cho các ứng dụng hạng nặng |

| Độ cứng bề mặt | HRC 55-60 | Độ sâu cứng: 15-20mm |

| Độ cứng lõi | HB 240-280 | Đảm bảo độ bền và khả năng chống va đập |

| Khả năng tải tối đa | 5 Tấn – 100+ Tấn trên mỗi bánh xe | Phụ thuộc vào kích thước bánh xe và vật liệu |

Ghi chú: Các thông số trên là thông số chung. Thông số kỹ thuật chính xác phải được xác định dựa trên yêu cầu vận hành và thiết kế cần cẩu của bạn.

Chúng tôi cung cấp đầy đủ các loại bánh xe cẩu để đáp ứng nhu cầu đa dạng.

1. Bánh xe mặt bích đôi: Loại phổ biến nhất, có mặt bích ở cả hai bên để dẫn hướng cần cẩu dọc theo đường ray một cách an toàn, preventing derailment.

2. Bánh xe mặt bích đơn: Được sử dụng trong các cấu hình cụ thể trong đó một bên của bánh xe chạy ngược với thanh dẫn hướng, thường thấy trong các hệ thống cầu trục chuyên dụng hoặc để bù đắp cho các vấn đề về theo dõi.

3. không bích (Đơn giản) Bánh xe: Được sử dụng kết hợp với các con lăn dẫn hướng ngang riêng biệt. Phổ biến trong các ứng dụng có tải trọng rất nặng như cần cẩu nạp lò hoặc nơi có lực ngang cao.

1. Bánh xe dẫn động: Có rãnh hoặc rãnh then được gia công trên mặt lốp hoặc mặt bên để ăn khớp với bánh răng dẫn động hoặc được dẫn động trực tiếp qua trục. Họ cung cấp động lực cho cần cẩu.

2. Người làm biếng (Chạy tự do) Bánh xe: Những bánh xe này không được dẫn động và quay tự do, hỗ trợ tải và theo chuyển động của các bánh xe dẫn động.

1. Bánh xe thép tiêu chuẩn: For general indoor industrial use.

2. Bánh xe thép hợp kim: Đối với nhiệm vụ nặng nề, ứng dụng chu kỳ cao (VÍ DỤ., 42CRMO).

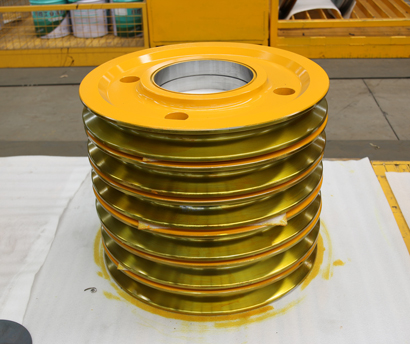

3. Bánh xe thép được xử lý nhiệt: Dành cho chu kỳ làm việc khắc nghiệt và khả năng chống mài mòn tối đa.

4. Bánh xe thép không gỉ: For corrosive environments (chế biến thực phẩm, Cây hóa học).

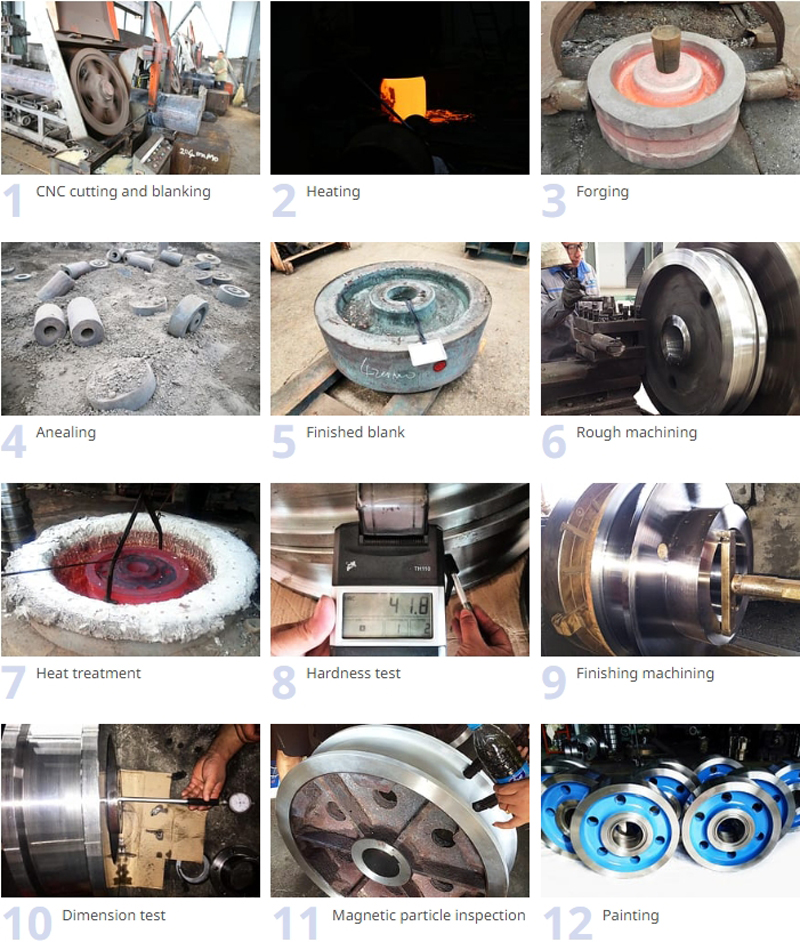

5. Bánh xe thép rèn: Dành cho các ứng dụng đòi hỏi khắt khe nhất đòi hỏi độ bền và khả năng chống va đập vượt trội.

Q1: Làm thế nào để biết khi nào bánh xe cẩu trên cao của tôi cần được thay thế?

MỘT: Regular inspection is key. Các dấu hiệu phổ biến bao gồm:

Q2: Can I replace just one worn wheel?

MỘT: Nên thay bánh xe theo bộ trên cùng một xe tải hoặc, lý tưởng nhất, qua toàn bộ cầu cẩu. Chỉ thay thế một bánh xe có thể dẫn đến phân bố tải không đều, gây ra tình trạng mòn nhanh và không đều trên bánh xe mới và các vấn đề tiềm ẩn về căn chỉnh.

Q3: Sự khác biệt giữa làm cứng ngọn lửa và làm cứng cảm ứng là gì?

MỘT: Cả hai quá trình đều làm cứng bề mặt bánh xe.

Q4: Độ cứng của bánh xe quan trọng như thế nào so với độ cứng của đường ray?

MỘT: Nó rất quan trọng. Lý tưởng nhất, bánh xe cẩu phải cứng hơn đường ray. Bánh xe cứng hơn sẽ mòn chậm hơn, chuyển sự mài mòn sang đường ray, which is typically longer, rẻ hơn, and easier to replace than a wheel set. A common rule is for the wheel to be 20-40 HB points harder than the rail.

Q5: Do you provide custom-made wheels?

MỘT: Đúng, we specialize in providing custom solutions. Chúng tôi có thể sản xuất bánh xe theo bản vẽ cụ thể của bạn, including non-standard diameters, chiều rộng, kích thước lỗ khoan, and special heat treatment requirements. Vui lòng cung cấp thông số kỹ thuật của bạn để báo giá.

Q6: Tôi cần cung cấp thông tin gì để đặt mua bánh xe thay thế chính xác?

MỘT: Để đảm bảo sự phù hợp hoàn hảo, vui lòng cung cấp:

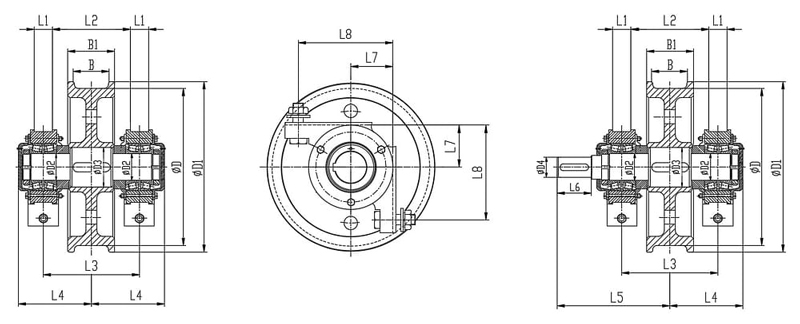

1. Wheel Outside Diameter and Tread Width.

2. Bore Diameter and Keyway Dimensions (Nếu có).

3. Flange Height and Profile.

4. Overall Width of the Wheel.

5. Hình ảnh của bánh xe cũ và lắp ráp cũng có thể rất hữu ích.

Chúng tôi coi trọng phản hồi của bạn! Vui lòng hoàn thành biểu mẫu bên dưới để chúng tôi có thể điều chỉnh các dịch vụ của mình theo nhu cầu cụ thể của bạn.

Product Overview Designed specifically for the harsh and demanding conditions of materi……

Khám phá thêm →

Aluminium smelter operations are characterized by harsh working environments, high-temp……

Khám phá thêm →

Tổng quan về sản phẩm Ròng rọc dây cáp của cần trục là một bộ phận quan trọng trong máy nâng……

Khám phá thêm →

Nhấp vào nút để nhận thông tin sản phẩm và báo giá trên WhatsApp.

Nhận báo giá

Nhận xét mới nhất