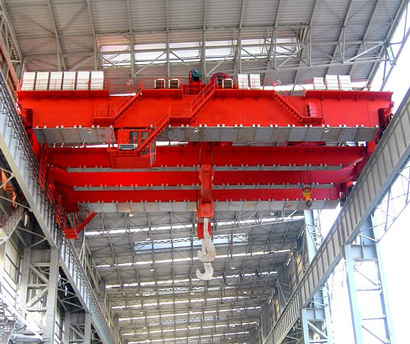

Bánh xe cần trục là rất quan trọng, các bộ phận có độ chính xác cao tạo thành giao diện cơ bản giữa cần trục và ray đường băng của nó.

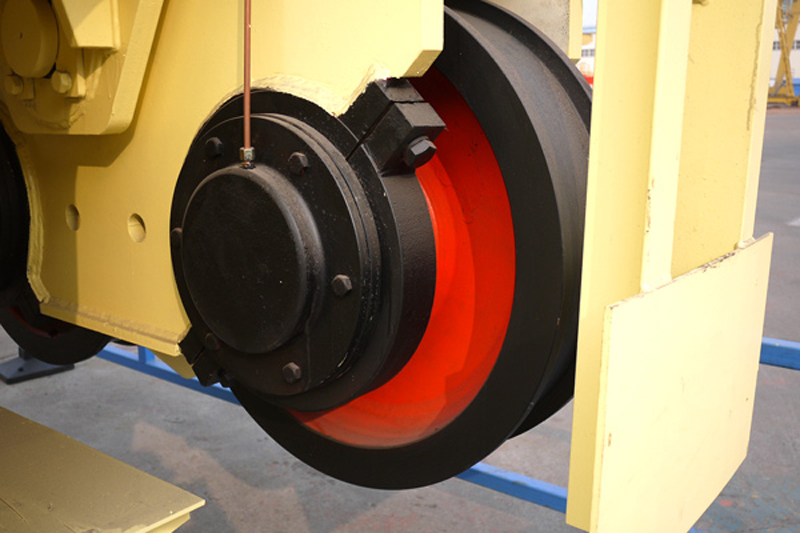

Bánh xe cẩu có nhiệm vụ chịu toàn bộ tải trọng của cần trục, bao gồm cả vật liệu được nâng lên, và tạo điều kiện thuận lợi, an toàn, và di chuyển theo chiều dọc hiệu quả dọc theo con đường được xác định. Được thiết kế cho độ bền và hiệu suất cực cao, những bánh xe này ảnh hưởng trực tiếp đến an toàn vận hành của cần cẩu, tuổi thọ, và mức độ tiếng ồn. Được sản xuất từ hợp kim có độ bền cao và được xử lý nhiệt nghiêm ngặt, bánh xe cần trục của chúng tôi được thiết kế để chịu được áp lực lớn, tải sốc, và mài mòn trong môi trường công nghiệp đòi hỏi khắt khe nhất, từ nhà máy thép và cảng vận chuyển đến xưởng chế tạo nặng.

1. Độ bền đặc biệt & Chống mài mòn

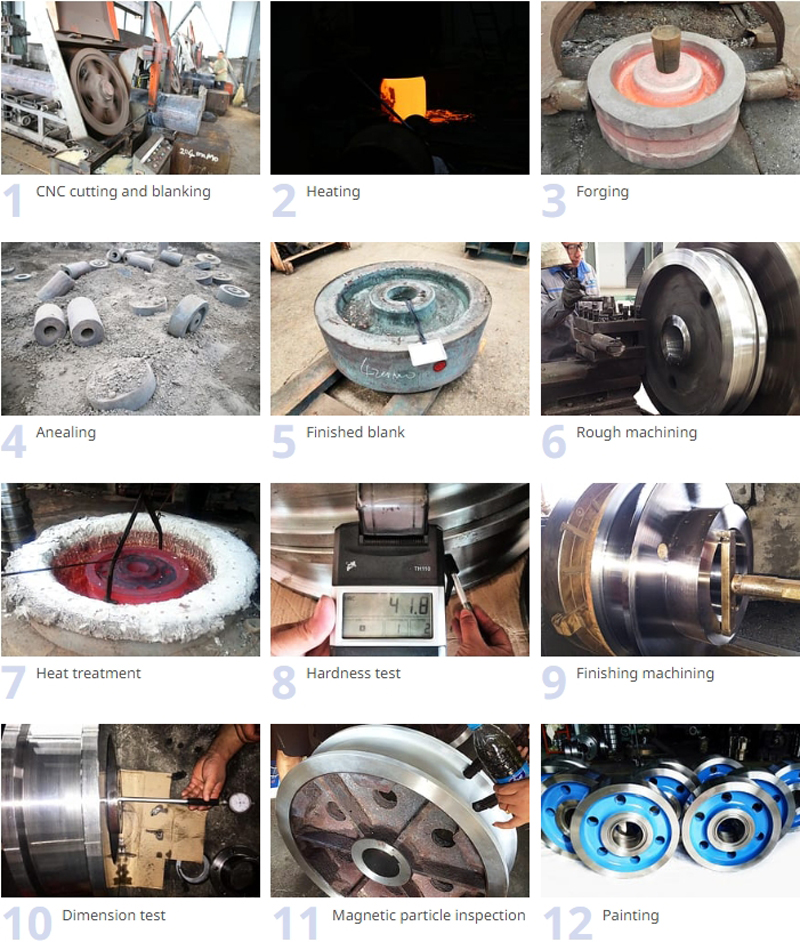

Được rèn từ thép cacbon cao hoặc thép hợp kim (VÍ DỤ., 65Mn, 42CRMO), bánh xe của chúng tôi có độ bền kéo và độ cứng vượt trội.

Các quy trình xử lý nhiệt tiên tiến như làm nguội và ủ tạo ra độ cứng, bề mặt bên ngoài chống mài mòn (vành) trong khi vẫn duy trì một thái độ cứng rắn, lõi giảm chấn.

2. Khả năng chịu tải cao

Được thiết kế chính xác để xử lý tải tĩnh và động, đảm bảo hoạt động ổn định dưới công suất định mức tối đa của cần trục mà không bị biến dạng.

3. Cấu hình gai lốp được tối ưu hóa & Thiết kế mặt bích

Cấu hình mặt lốp được gia công để khớp hoàn hảo với đường viền của đường ray cần cẩu (VÍ DỤ., CHÚNG TÔI MUA, KRUPP, đường sắt phẳng), đảm bảo diện tích tiếp xúc tối đa và giảm ứng suất điểm.

Mặt bích được thiết kế để cung cấp hướng dẫn an toàn, ngăn ngừa trật bánh đồng thời giảm thiểu ma sát và mài mòn ở phía đường ray.

4. Gia công chính xác

Mỗi bánh xe đều trải qua quá trình gia công và mài chính xác để đạt được dung sai nghiêm ngặt về đường kính, độ đồng tâm, và hoàn thiện bề mặt. Điều này đảm bảo xoay trơn tru, giảm độ rung, và kéo dài tuổi thọ của cả bánh xe và đường ray.

5. Ghế chịu lực chắc chắn

Lỗ khoan và rãnh then được gia công chính xác để đảm bảo khớp hoàn hảo với trục và vòng bi, đảm bảo truyền tải điện hiệu quả và ngăn ngừa trượt hoặc hỏng hóc sớm.

6. Tùy chọn tùy chỉnh

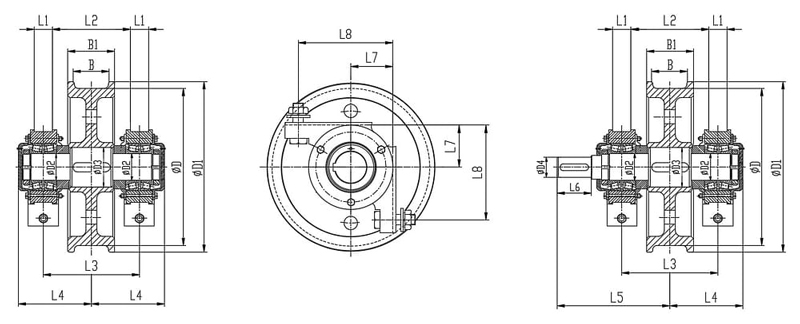

Chúng tôi cung cấp bánh xe có thể tùy chỉnh hoàn toàn phù hợp với yêu cầu cụ thể của bạn, bao gồm đường kính, chiều rộng, kích thước lỗ khoan, chiều cao mặt bích, và loại vật liệu phù hợp với mô hình và ứng dụng cần trục độc đáo của bạn.

Bảng sau đây cung cấp thông số kỹ thuật tiêu chuẩn. Kích thước và vật liệu tùy chỉnh có sẵn theo yêu cầu.

| Tham số | Phạm vi đặc điểm kỹ thuật | Ghi chú |

|---|---|---|

| Đường kính bánh xe | 250 – 1000+mm | Đường kính tùy chỉnh có sẵn |

| Chiều rộng rãnh | 90 – 200+mm | Phù hợp với chiều rộng đầu đường sắt |

| Đường kính lỗ khoan | 80 – 200+mm | Gia công chính xác với rãnh then |

| Chiều cao mặt bích | 25 – 45mm | Tiêu chuẩn hoặc theo yêu cầu |

| Lớp vật liệu | 65Mn, 42CRMO, 55# Thép, C45 | Thép hợp kim khác có sẵn |

| Độ cứng bề mặt | 45 - 60 HRC | Đạt được thông qua xử lý nhiệt |

| Độ cứng lõi | 240 - 280 HB | Đảm bảo độ bền và khả năng chống va đập |

| Tối đa. Tải trọng bánh xe | 5 - 100+ Tấn | Mỗi bánh xe, phụ thuộc vào cấu hình |

Bánh xe cần trục được phân loại dựa trên loại mặt bích và vật liệu/kết cấu của chúng.

1. Bánh xe mặt bích đôi:

2. Bánh xe mặt bích đơn:

3. Bánh xe không bích:

1. Bánh xe thép rèn:

Được sản xuất thông qua quy trình rèn để căn chỉnh cấu trúc hạt, dẫn đến sức mạnh vượt trội, chống va đập, và cuộc sống mệt mỏi. Chúng là sự lựa chọn cao cấp cho các ứng dụng nặng và chu kỳ cao.

2. Bánh xe thép đúc:

Được làm bằng cách đổ thép nóng chảy vào khuôn. Một giải pháp tiết kiệm chi phí cho các ứng dụng tiêu chuẩn. Chất lượng phụ thuộc nhiều vào quá trình đúc để tránh các khuyết tật bên trong.

3. Bánh xe thép hợp kim:

Được làm từ hợp kim thép như 42CrMo hoặc 65Mn, mang lại sự cân bằng tuyệt vời giữa độ cứng bề mặt cao và độ bền sâu sau khi xử lý nhiệt. Đây là loại vật liệu phổ biến và được khuyên dùng nhất cho cổng trục công nghiệp.

4. Bánh xe cứng:

Trải qua quá trình xử lý nhiệt cụ thể (VÍ DỤ., cacbon hóa) để tạo ra một thứ cực kỳ khó khăn, lớp bề mặt chống mài mòn trong khi vẫn giữ được độ mềm, lõi dẻo. Tuyệt vời cho các ứng dụng có độ mòn tiếp xúc lăn và mài mòn rất cao.

Q1: Chức năng chính của bánh xe cần trục là gì?

MỘT: Bánh xe cần trục là bộ phận cơ bản phục vụ hai mục đích chính: để hỗ trợ toàn bộ trọng lượng (trọng tải) của cần trục và các vật liệu nâng của nó, và dẫn hướng cần cẩu dọc theo đường ray một cách trơn tru và an toàn.

Q2: Bao lâu nên kiểm tra bánh xe cần trục?

MỘT: Chúng tôi khuyên bạn nên kiểm tra trực quan trước mỗi ca làm việc để tìm dấu hiệu hao mòn, vết nứt, hoặc thiệt hại. Một cách chính thức, việc kiểm tra chi tiết phải được tiến hành hàng tháng bởi một kỹ thuật viên có trình độ. Tần số chính xác phụ thuộc vào chu kỳ làm việc của cần trục, cường độ tải, và môi trường hoạt động.

Q3: Các dấu hiệu phổ biến của bánh xe cần trục bị hỏng là gì?

MỘT: Các dấu hiệu cảnh báo phổ biến bao gồm:

Q4: Làm cách nào để chọn vật liệu phù hợp cho bánh xe cần cẩu của tôi?

MỘT: Sự lựa chọn phụ thuộc vào nhu cầu ứng dụng của bạn:

Q6: Tải trọng bánh xe tối đa được tính như thế nào?

MỘT: Tải trọng tối đa của bánh xe là giá trị được tính toán dựa trên tổng trọng lượng của cần trục, sức nâng của nó, số lượng bánh xe, và phân bố tải. Đây là một thông số an toàn quan trọng. Đội ngũ kỹ thuật của chúng tôi có thể hỗ trợ xác minh khả năng chịu tải bánh xe cần thiết cho hệ thống của bạn.

Tất cả các thông số kỹ thuật và dữ liệu được cung cấp chỉ nhằm mục đích tham khảo. Thiết kế và thông số kỹ thuật cuối cùng phải được xác nhận dựa trên mô hình cần trục cụ thể, hạng nhiệm vụ, và điều kiện hoạt động. Liên hệ với nhóm kỹ thuật của chúng tôi để có giải pháp phù hợp.

Chúng tôi coi trọng phản hồi của bạn! Vui lòng hoàn thành biểu mẫu bên dưới để chúng tôi có thể điều chỉnh các dịch vụ của mình theo nhu cầu cụ thể của bạn.

Giới thiệu sản phẩm Cần cẩu có khoảng không trên cao thấp là một loại vật liệu chuyên dụng……

Khám phá thêm →

As a core equipment in heavy industrial lifting operations, các 90 tons overhead crane ……

Khám phá thêm →

Tổng quan về sản phẩm Một cần cẩu di chuyển trên cao, còn được gọi là cần cẩu trên cao hoặc cầu……

Khám phá thêm →

Nhấp vào nút để nhận thông tin sản phẩm và báo giá trên WhatsApp.

Nhận báo giá

Nhận xét mới nhất