Overhead cranes are workhorses in manufacturing plants, будівельні майданчики, and warehouses, playing a crucial role in lifting and moving heavy loads. Однак, their safe and efficient operation relies heavily on regular and thorough inspections. Neglecting inspections can lead to equipment failure, workplace accidents, і дорогий час простою. У цьому блозі, we’ll walk you through a step-by-step guide on how to inspect an overhead crane properly.

Передінспекційна підготовка

Перед початком огляду, proper preparation is essential to ensure the process is safe and effective.

- 1. Перегляд документації: Gather the crane’s operation manual, maintenance records, and previous inspection reports. This helps you understand the crane’s history, any past issues, and specific inspection requirements.

- 2. Prepare Tools and Equipment: Equip yourself with necessary tools such as a flashlight, вимірювальна стрічка, динамометричний ключ, оглядове дзеркало, and a camera for documenting findings. Також, ensure you have personal protective equipment (ЗІЗ) like a hard hat, safety shoes, рукавички, and a harness if working at height.

- 3. Secure the Area: Block off the area around the crane to prevent unauthorized access. Put up warning signs and ensure no one is working or walking under the crane during the inspection.

- 4. Check Power Supply: Ensure the crane’s power is turned off and locked out/tagged out (СЕРЦЕ) to avoid accidental activation during the inspection.

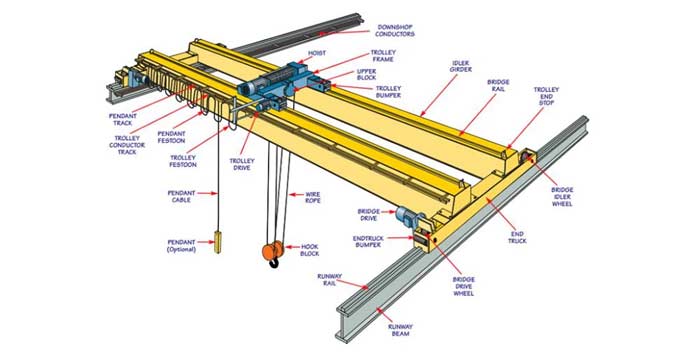

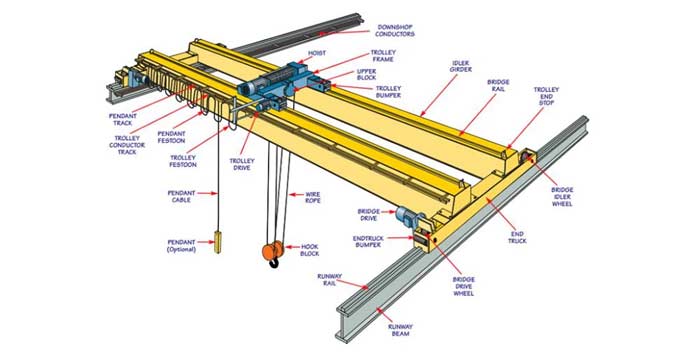

Visual Inspection of Key Components

A detailed visual inspection is the foundation of crane inspection. Focus on the following critical components:

1. Підйомна система

Підйомна система

- Overhead Crane Hook: Перевірте наявність тріщин, деформація, wear on the hook throat or shank, and damage to the latch. Ensure the hook rotates freely and the latch is functioning properly to prevent loads from slipping.

- Wire Rope: Inspect for broken wires, перегини, корозія, знос, and improper lubrication. Pay attention to areas near the drum and sheaves where wear is more common. Measure the rope diameter to check for excessive wear—if it’s below the manufacturer’s recommended limit, replace the rope.

- Drum and Sheaves: Шукайте тріщини, wear on the drum flange or sheave grooves, and misalignment. Ensure the крановий канатний барабан is not damaged and the rope is properly seated in the grooves without overlapping.

- Brake System: Check the brake pads for wear, proper adjustment, and contamination (oil or dust). Test the brake operation to ensure it can hold the rated load securely.

2. Bridge and Trolley

візок

- Балка мосту: Inspect the bridge girder for cracks, згинання, or distortion. Check the connections between the girder and end trucks for tightness and signs of wear.

- Візок: Examine the trolley wheels for wear, тріщина, and proper alignment. Check the trolley drive mechanism, including gears and bearings, for unusual noise or damage.

- Runway Rails: Inspect the runway rails for straightness, levelness, і носити. Look for loose fasteners, damaged rail joints, and debris on the rails that could interfere with the crane’s movement.

3. Електрична система

crane radio control

- Cables and Wires: Check for frayed cables, loose connections, and damaged insulation. Ensure cables are properly supported and not dragging or rubbing against other components.

- Панель управління: Inspect the control panel for signs of overheating, корозія, or water damage. Test the buttons, switches, and indicators to ensure they are functioning correctly.

- Limit Switches: Verify the operation of upper and lower limit switches for the hoist, as well as travel limit switches for the bridge and trolley. These switches prevent the crane from moving beyond safe limits.

Operational Testing

After the visual inspection, perform operational tests to ensure the crane functions properly under load (якщо застосовно) and no-load conditions.

- 1. No-Load Test: Turn on the power and test the hoist, міст, and trolley movements in all directions. Check for smooth operation, незвичайні звуки, and proper braking. Ensure the limit switches activate when the crane reaches the safe limits.

- 2. Load Test: Conduct a load test using a test load that is 100% до 125% від номінальної вантажопідйомності крана (follow manufacturer guidelines). Slowly lift the load, move it horizontally, and lower it. Observe for any excessive deflection of the bridge girder, unusual noises from components, or issues with the brake system. Ensure the load remains stable throughout the test.

- 3. Post-Test Checks: After completing operational tests, turn off the power and perform a final visual check of key components to ensure no new issues arose during testing. Check for any loose fasteners or signs of stress that may have developed.

Documentation and Follow-Up

Thorough documentation and timely follow-up are indispensable to maintain the crane’s safety record and address issues promptly. Skipping this step can lead to overlooked problems that escalate into major hazards.

- 1. Record Inspection Details: Document every aspect of the inspection, including the date, ім'я інспектора, crane identification number, and a comprehensive list of components checked. For each component, note its condition—whether it’s in good shape, shows minor wear, or has critical defects. Attach photos or videos of problematic areas to provide visual evidence.

- 2. Classify Defects by Severity: Categorize defects to prioritize repairs: – Critical: Defects that pose immediate danger (Напр., cracked hook, broken wire ropes). The crane must be taken out of service immediately until repairs are completed and verified. – Major: Issues that could become critical soon (Напр., worn brake pads below recommended thickness). Schedule repairs within a short timeframe, and restrict the crane’s use if necessary. – Minor: Cosmetic damage or slight wear that doesn’t affect safety (Напр., minor paint chipping). Address these during routine maintenance.

- 3. Update Maintenance Logs: Integrate the inspection report into the crane’s official maintenance log. This log should track all inspections, ремонти, заміни, and lubrication schedules. It serves as a historical record for future inspections and helps identify recurring issues.

- 4. Communicate and Assign Actions: Share the inspection report with relevant stakeholders, including maintenance teams, supervisors, and crane operators. Assign clear responsibilities for repairing defects—specify who will do the work, when it will be completed, and how it will be verified. Follow up to ensure all actions are carried out as planned.

How often do overhead cranes need to be inspected?

The frequency of overhead crane inspections depends on usage, середовище, and regulatory requirements. Ось загальні вказівки:

- 1. Daily Inspections: Conducted by the operator before each shift. Check for obvious issues like damaged hooks, loose cables, or abnormal noises during startup.

- 2. Щомісячні/квартальні перевірки: Performed by maintenance personnel. Include a more detailed visual check and basic operational tests.

- 3. Щорічні перевірки: Comprehensive inspections by qualified inspectors (certified by relevant authorities). This includes load testing, detailed component measurements, and electrical system diagnostics.

- 4. Після капітального ремонту або аварії: Inspect the crane thoroughly after any significant repairs, modifications, або інциденти (Напр., overload, collision) to ensure it’s safe to operate.

Висновок

Inspecting an overhead crane is a systematic process that combines preparation, visual checks, operational testing, documentation, and follow-up. By adhering to this guide, you not only comply with safety regulations but also protect your workforce from accidents and extend the crane’s service life. Запам'ятати, safety should never be compromised—regular inspections are an investment in preventing costly downtime and tragic incidents. If you’re unsure about any aspect of the inspection, consult a qualified crane inspector or the manufacturer for guidance.

FAQ About Overhead Crane Inspection Checklist

Q1: What key sections are typically included in an overhead crane inspection checklist?

A: A standard checklist covers pre-inspection preparation (documentation review, tool/PPE preparation, area securing, СЕРЦЕ), visual inspection of key components (hoist system, bridge/trolley, електрична система), operational testing (no-load, навантаження, post-test checks), and documentation/follow-up (recording findings, defect classification, maintenance log updates).

Q2: How does the inspection frequency differ for daily vs. annual checks in the checklist?

A: Daily checks (by operators) focus on obvious issues like damaged hooks, loose cables, or startup noises. Annual checks (by qualified inspectors) are comprehensive, включаючи тестування навантаження (100%-125% номінальна потужність), detailed component measurements, and electrical diagnostics—both are mandatory in most checklists to cover short-term and long-term safety.

Q3: Who is responsible for completing the overhead crane inspection checklist?

A: Daily checklists are completed by the crane operator before each shift. Monthly/quarterly checklists are handled by maintenance personnel. Annual and post-repair checklists must be filled out by certified qualified inspectors (per OSHA or local regulatory standards) to ensure compliance.

Q4: Why is defect classification important in the inspection checklist?

A: Classifying defects (критичний, major, minor) in the checklist helps prioritize action. Critical defects (Напр., cracked hooks) require immediate shutdown; major issues (Напр., worn brake pads) need prompt repairs; minor ones (Напр., paint chipping) go to routine maintenance. This prevents overlooked hazards and streamlines repair workflows.

Q5: Can the checklist be customized for different types of overhead cranes?

A: Так. While core sections are universal, checklists should be tailored to crane types (Напр., bridge cranes, козлові крани) and usage scenarios (heavy-duty vs. light-duty). Наприклад, a port gantry crane’s checklist may add extra checks for weather-resistant components, while a warehouse bridge crane may emphasize runway rail alignment.

Останні коментарі