An Electric Overhead Traveling (EOT) Crane is a type of industrial crane designed for lifting, alçaltma, and moving heavy loads horizontally within a facility.

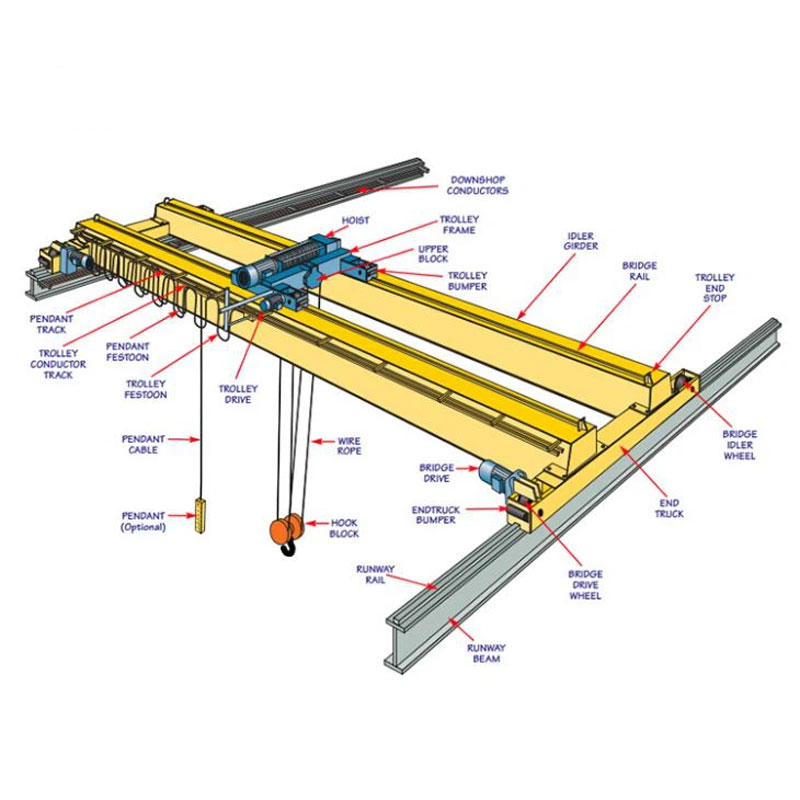

EOT Crane Structure Diagram

EOT crane is a fundamental piece of equipment in manufacturing, toplantı, and storage operations. The defining characteristic of an EOT crane is that it operates on a fixed runway system, typically consisting of two parallel beams (runway rails) attached to the building’s support structure.

The crane itself “travels” along these rails, covering the length of the bay, while a hoisting mechanism moves across the crane’s bridge, covering the width. This combination of movements allows the crane to serve virtually every point within its rectangular working area.

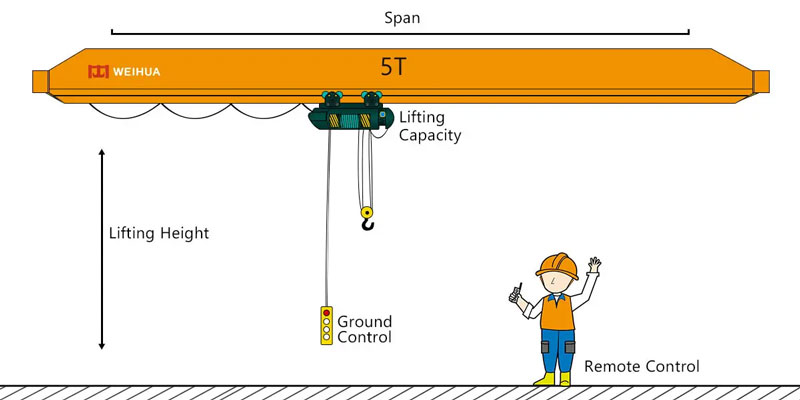

10 Tons EOT Crane

EOT Cranes are primarily categorized by their bridge structure and the number of beams they use. The two most common types are:

5 Ton Tek Kirişli EOT Vinç

A Tek Kirişli EOT Vinç features one main bridge beam on which the hoist and trolley operate. The hoist is typically mounted on a trolley that moves along the bottom flange of the girder.

Anahtar Özellikler:

Ideal For: Lighter to moderate duty cycles, capacities generally up to 20 ton, and applications where cost and headroom are primary concerns. Common in workshops, depolar, and smaller manufacturing plants.

A Double Girder EOT Crane is constructed with two main bridge beams that support the trolley and hoist. The trolley runs on rails mounted on top of the two girders.

Anahtar Özellikler:

Ideal For: Heavy-duty applications, sık kullanım, high capacities, çelik fabrikaları, dökümhaneler, enerji santralleri, and large-scale shipping ports.

Top-Running vs. Under-Running: This refers to how the crane moves on the runway. Top-running cranes (described above) ride on rails atop the runway beams. Under-running (or underhung) cranes have end trucks that suspend the crane from the bottom flange of the runway beams.

Portal vinç: A variant where the bridge is supported by two or more legs running on fixed rails at ground level, instead of being attached to a building structure. It is essentially a “self-supporting” EOT crane.

başvuru

EOT Cranes are the workhorses of heavy industry due to their efficiency and reliability. Their primary application scenarios include:

Özetle, whether you need a cost-effective Single Girder EOT Crane for light-duty tasks or a robust Double Girder EOT Crane for heavy, intensive applications, this material handling solution is engineered to improve productivity, enhance safety, and streamline your operations.

Geri bildiriminize değer veriyoruz! Hizmetlerimizi özel ihtiyaçlarınıza göre uyarlayabilmemiz için lütfen aşağıdaki formu doldurun.

Product Overview Designed specifically for the harsh and demanding conditions of materi……

Daha Fazla Keşfedin →

Bizim 16 tonluk gezer vinç, üst düzey bir kaldırma çözümü olarak öne çıkıyor, mühendislik……

Daha Fazla Keşfedin →

Endüstriyel tesislerin zorlu ortamında, verimli ve güvenli güç kaynağı……

Daha Fazla Keşfedin →

Son Yorumlar