A double girder overhead crane is a robust material handling equipment designed to lift and transport heavy loads in industrial settings.

A double girder overhead crane is a robust material handling equipment designed to lift and transport heavy loads in industrial settings. Engineered with two parallel main girders, it delivers superior stability and load-bearing capacity compared to single girder models, making it the go-to choice for heavy-duty applications such as steel mills, üretim tesisleri, depolar, ve şantiyeler. Whether you need to move machinery, İşlenmemiş içerikler, veya bitmiş ürünler, our double girder overhead cranes combine precision, dayanıklılık, and safety to optimize your workflow.

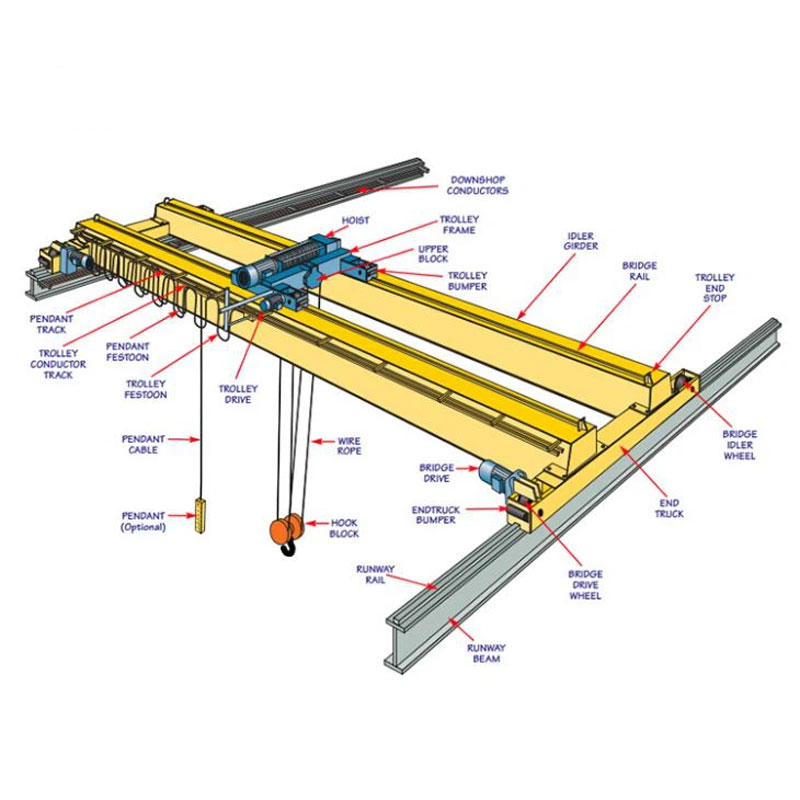

A double girder overhead crane is a type of bridge crane consisting of two horizontal main girders supported by end trucks (or end carriages) that run along elevated rails (runways) mounted on building columns or standalone structures. The crane’s lifting mechanism—typically a hoist or trolley—is mounted on a trolley that travels along the length of the main girders, allowing 360° coverage of the workspace below.

Unlike single girder overhead cranes, which rely on a single main beam, double girder designs distribute weight more evenly, enabling them to handle much heavier loads (often up to 500 tons or more). This makes them essential for industries requiring frequent heavy lifting, where reliability and safety are non-negotiable.

Our double girder overhead cranes are built to excel in demanding environments. Here are their standout features:

|

Parametre

|

Aralık/Ayrıntılar

|

|

Maksimum Kaldırma Kapasitesi

|

10 tons – 500 ton (custom options available for higher loads)

|

|

Aralık uzunluğu

|

10m – 35m (custom spans on request)

|

|

Kaldırma yüksekliği

|

6m – 30m (adjustable based on application)

|

|

Kaldırma Hızı

|

0.5m/dak – 10m/dak (variable speed with frequency inverter option)

|

|

Tramvay Seyahat Hızı

|

5m/dak – 30m/dak

|

|

Vinç Seyir Hızı

|

10m/dak – 50m/dak

|

|

İşçi sınıfı

|

A5 – A8 (ISO Standardı; suitable for light to heavy-duty, continuous use)

|

|

Güç kaynağı

|

380V/3Ph/50Hz (customizable for 220V/440V or other regions)

|

|

Kontrol modu

|

Sarkıt kontrolü, uzaktan kumanda (wireless), veya kabin kontrolü

|

A double girder overhead crane consists of several key components working together to ensure efficient lifting and movement:

Main Girders

Two parallel steel beams (kirişler) that form the bridge structure. They bear the load of the trolley and the lifted material, requiring high strength and rigidity.

Son Kamyonlar

Mounted at both ends of the main girders, these house the wheels and motors that drive the crane along the runway rails.

Arabası

A movable unit that travels along the top or bottom of the main girders. It carries the hoist and is powered by its own motor for horizontal movement.

Vinç

The lifting mechanism, including a crane drum, wire rope/cable, Ve vinç kancası. It is responsible for raising and lowering loads, with options for electric or hydraulic operation.

Elektrik Sistemi

Includes motors, kontrol panelleri, switches, and wiring to power and operate the crane, tramvay, ve kaldırma.

Kaldırma Yüksekliği Sınırlayıcı

Overload limiters, travel limit switches, emergency stop systems, and anti-sway devices to ensure safe operation.

Çeyrek: What’s the difference between a double girder and single girder overhead crane?

A: Double girder cranes have two main girders, offering higher load capacity (10+ ton) ve istikrar, making them suitable for heavy-duty use. Single girder cranes have one main girder, daha hafif, and better for lighter loads (kadar 10 ton) in smaller workspaces.

Çubuk: Which industries use double girder overhead cranes?

A: They are widely used in steel mills, automotive manufacturing, tersaneler, Şantiyeler, depolar (for heavy pallet handling), and power plants.

Çeyrek: How often should a double girder overhead crane be maintained?

A: Rutin denetimler (daily checks for wear, yağlama) and professional maintenance (every 6–12 months) are recommended to ensure safety and longevity.

Çeyrek: Can double girder cranes be customized for specific applications?

A: Evet. We offer customizations for load capacity, açıklık, kaldırma yüksekliği, control systems, and specialized attachments (Örn., magnets for metal handling, grabs for bulk materials).

Q5: Are double girder overhead cranes compliant with international safety standards?

A: Our cranes meet ISO, Fem, and OSHA standards, with built-in safety features to ensure compliance with global industrial regulations.

PDF ile paylaş: İndirmek

Geri bildiriminize değer veriyoruz! Hizmetlerimizi özel ihtiyaçlarınıza göre uyarlayabilmemiz için lütfen aşağıdaki formu doldurun.

. 100 tons gantry crane is a high-performance, heavy-duty lifting equipment designed ……

Daha Fazla Keşfedin →

Arabalı elektrikli zincirli vinç, aşağıdakileri gerçekleştirmek üzere tasarlanmış entegre bir kaldırma ekipmanıdır:

Daha Fazla Keşfedin →

Patlamaya dayanıklı Tek Kirişli Gezer Vinç, özel bir kaldırma ekipmanıdır.

Daha Fazla Keşfedin →

Son Yorumlar