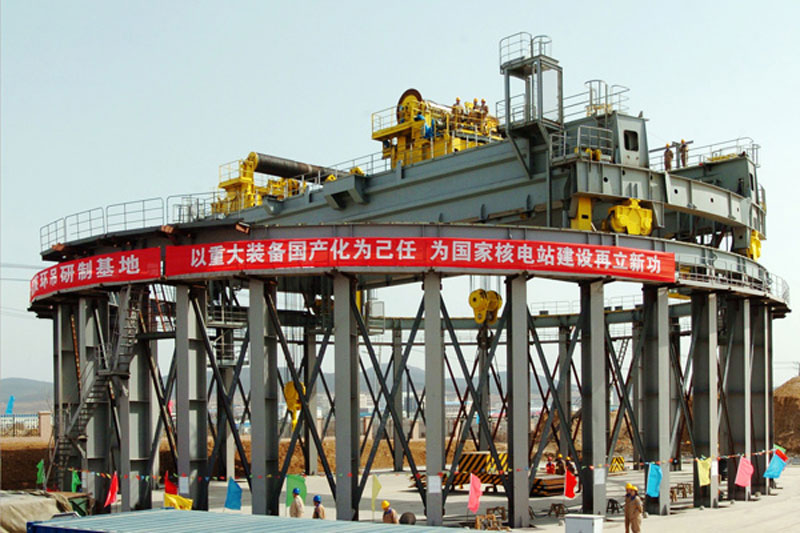

Ağır kaldırma dünyasında, çok az ortam bu kadar hassasiyet gerektirir, güvenilirlik, and outright rigor as a nuclear power plant. Here, every component is critical, and every procedure is governed by layers of safety protocols. At the heart of many of these operations is a seemingly simple piece of equipment: vinç kancası.

But this is no ordinary hook. Lifting a load in a nuclear facility isn’t just about weight; it’s about safety, kesinlik, and preventing consequences that are unthinkable. The standards governing nuclear plant crane hooks are among the most stringent in the world. Let’s break down why.

Imagine the stakes. A crane in a nuclear plant might be tasked with:

1. Handling multi-ton radioactive reactor components during refueling.

2. Moving spent nuclear fuel assemblies, which are both extremely heavy and highly radioactive.

3. Transporting essential safety equipment that must be available in an emergency.

A failure here isn’t just a dropped load; it could cause catastrophic damage to critical infrastructure, release radioactive material, or endanger the entire plant’s operation. Öyleyse, the hooks used must be designed and maintained to a level of integrity that leaves absolutely nothing to chance.

The design, manufacture, test, and inspection of these hooks are not left to manufacturer discretion. They are strictly dictated by a framework of codes and standards, primarily:

1. ASME NOG-1: Rules for Construction of Overhead and Gantry Cranes (Top Running Bridge, Multiple Girder)

This is the bible for nuclear crane design in the United States and a key reference globally. NOG-1 outlines specific requirements for hooks that go far beyond standard industrial crane codes (ASME B30.10 gibi).

2. ASME B30.10: Kancalar

While B30.10 applies to hooks more generally, its guidelines on inspection, Bakım, and operation are considered the baseline for nuclear applications. Fakat, nuclear facilities always adhere to the more stringent NOG-1 rules where they apply.

3. ISO 19378: Cranes — Hoists and hooks — Requirements for use in nuclear facilities

This international standard provides a global framework, specifying requirements for equipment like hooks intended for use in nuclear installations. It covers design, üretme, test, and documentation, ensuring a consistent safety philosophy worldwide.

4. IEEE 387: Standard for Criteria for Diesel-Generator Units Applied as Standby Power Supplies for Nuclear Power Generating Stations

While primarily about generators, this standard exemplifies the overarching philosophy. Every supporting system, including the cranes that might move emergency equipment, must meet extreme reliability criteria.

A perfect hook is useless without perfect care. Nuclear standards mandate an aggressive inspection regime:

Any hook found with a crack, any twist exceeding 10 dereceler, or wear that reduces its original dimension by more than 5-10% must be removed from service immediately and permanently.

The standards for a nuclear plant crane hook represent more than just a checklist of technical requirements. They embody an entire ethos of nuclear safety: redundancy, kalite, and predictability.

Every curve of that forged steel hook, every inspection report, and every proof test certificate is a testament to an industry that understands the profound responsibility it carries. It’s a powerful reminder that in nuclear safety, there is no such thing as “good enough.” The humble crane hook, built and maintained to these uncompromising standards, is a silent guardian of one of our most critical energy resources.

Geri bildiriminize değer veriyoruz! Hizmetlerimizi özel ihtiyaçlarınıza göre uyarlayabilmemiz için lütfen aşağıdaki formu doldurun.

Son Yorumlar