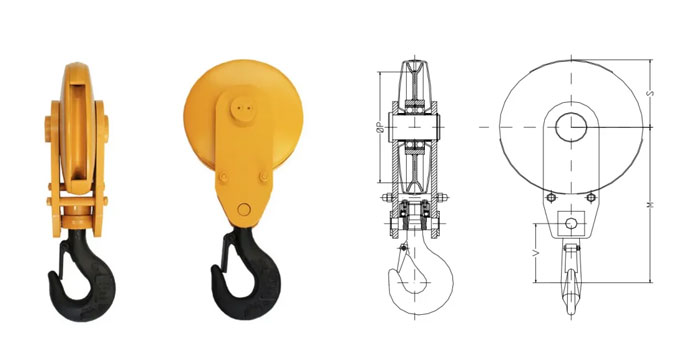

Construction sites rely heavily on cranes for lifting and moving heavy materials. One of the most critical components of a crane is the vinç kancası. Ensuring proper construction crane hook safety is vital to prevent accidents, protect workers, and maintain operational efficiency. Bu blog gönderisinde, we’ll explore the importance of crane hook safety, common hazards, inspection tips, and best practices for safe operation.

Crane hook failure can lead to catastrophic incidents, including dropped loads, yaralanmalar, ve ölümler. Given the high stakes, construction crane hook safety must be a top priority for site managers, crane operators, and maintenance teams.

1. Prevents accidents and injuries

2. Protects expensive equipment and materials

3. Ensures compliance with safety regulations (Örn., OSHA, ANSI)

4. Reduces downtime and repair costs

Understanding potential hazards helps in implementing effective safety measures. Some of the most common risks include:

1. Aşırı yükleme: Exceeding the rated load limit of the hook can lead to bending or breakage.

2. Wear and Tear: Hooks can develop cracks, deformasyon, or corrosion over time.

3. Improper Use: Side loading, point loading, or using damaged slings increases the chance of failure.

4. Lack of Maintenance: Infrequent inspections or poor maintenance can allow small issues to escalate into major failures.

Routine inspection and timely maintenance are essential for crane hook safety. Here are some key guidelines:

1. Inspect for cracks, distortion, ve korozyon

2. Ensure the latch (varsa) is functional

3. Verify that the hook swivels smoothly (Mümkünse)

1. Measure throat opening to check for excessive stretching

2. Look for wear on bearing surfaces

3. Use non-destructive testing (NDT) for internal flaws

4. Check manufacturer’s load limits and compare with actual usage

Tip: Replace hooks if there is more than 10% wear on any critical area or if the hook shows signs of deformation or cracks.

To ensure a safe lifting environment, consider these best practices:

1. Train Operators Thoroughly: Proper training helps operators understand crane limits, load handling techniques, and emergency procedures.

2. Use Proper Rigging Equipment: Match the hook size with the load and sling. Avoid using makeshift attachments or damaged rigging gear.

3. Avoid Shock Loading: Sudden lifting or dropping of loads can stress the crane hook beyond its design limits.

4. Implement a Safety Checklist: Use a construction crane hook safety checklist before every shift to ensure all components are in good condition.

5. Document and Report Issues: Any defects or incidents must be logged immediately and addressed by a qualified technician.

Safe lifting operations depend heavily on the integrity of the crane hook. By prioritizing construction crane hook safety, construction teams can significantly reduce the risk of accidents, maintain compliance, and promote a culture of safety on site. Düzenli denetimler, proper training, and adherence to best practices are key to achieving this goal.

Geri bildiriminize değer veriyoruz! Hizmetlerimizi özel ihtiyaçlarınıza göre uyarlayabilmemiz için lütfen aşağıdaki formu doldurun.

Son Yorumlar