A double girder overhead crane is a robust material handling equipment designed to lift and transport heavy loads in industrial settings.

A double girder overhead crane is a robust material handling equipment designed to lift and transport heavy loads in industrial settings. Engineered with two parallel main girders, it delivers superior stability and load-bearing capacity compared to single girder models, making it the go-to choice for heavy-duty applications such as steel mills, manufacturing plants, คลังสินค้า, และสถานที่ก่อสร้าง. Whether you need to move machinery, วัตถุดิบ, or finished products, our double girder overhead cranes combine precision, ความทน, and safety to optimize your workflow.

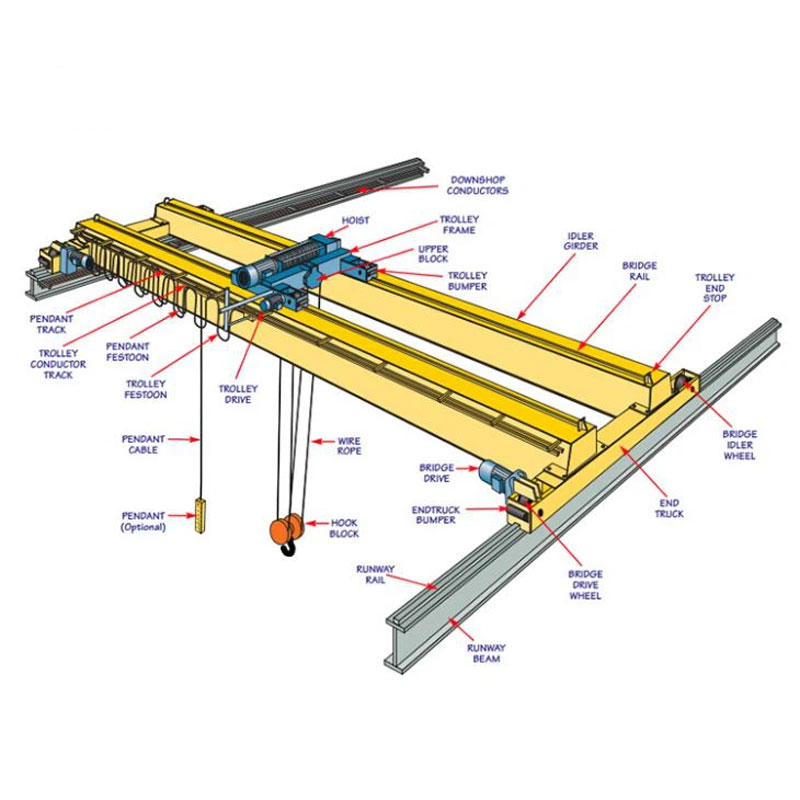

A double girder overhead crane is a type of bridge crane consisting of two horizontal main girders supported by end trucks (or end carriages) that run along elevated rails (runways) mounted on building columns or standalone structures. The crane’s lifting mechanism—typically a hoist or trolley—is mounted on a trolley that travels along the length of the main girders, allowing 360° coverage of the workspace below.

Unlike เครนเหนือศีรษะคานเดี่ยว, which rely on a single main beam, double girder designs distribute weight more evenly, enabling them to handle much heavier loads (often up to 500 tons or more). This makes them essential for industries requiring frequent heavy lifting, where reliability and safety are non-negotiable.

Our double girder overhead cranes are built to excel in demanding environments. Here are their standout features:

|

พารามิเตอร์

|

Range/Details

|

|

Maximum Lifting Capacity

|

10 tons – 500 ตัน (custom options available for higher loads)

|

|

ขยายความยาว

|

10m – 35m (custom spans on request)

|

|

ยกความสูง

|

6ม. – 30ม (adjustable based on application)

|

|

Hoist Speed

|

0.5ม./นาที – 10 ม./นาที (variable speed with frequency inverter option)

|

|

ความเร็วในการเดินทางของรถเข็น

|

5เมตร/นาที – 30ม./นาที

|

|

ความเร็วในการเดินทางของเครน

|

10เมตร/นาที – 50ม./นาที

|

|

ชนชั้นแรงงาน

|

A5 – A8 (มาตรฐาน ISO; suitable for light to heavy-duty, continuous use)

|

|

แหล่งจ่ายไฟ

|

380V/3Ph/50Hz (customizable for 220V/440V or other regions)

|

|

โหมดควบคุม

|

การควบคุมจี้, การควบคุมระยะไกล (wireless), หรือการควบคุมห้องโดยสาร

|

A double girder overhead crane consists of several key components working together to ensure efficient lifting and movement:

คานหลัก

Two parallel steel beams (girders) that form the bridge structure. They bear the load of the trolley and the lifted material, requiring high strength and rigidity.

End Trucks

Mounted at both ends of the main girders, these house the wheels and motors that drive the crane along the runway rails.

รถเข็น

A movable unit that travels along the top or bottom of the main girders. It carries the hoist and is powered by its own motor for horizontal movement.

Hoist

The lifting mechanism, including a crane drum, wire rope/cable, และ ตะขอเครน. It is responsible for raising and lowering loads, with options for electric or hydraulic operation.

ระบบไฟฟ้า

Includes motors, control panels, สวิตช์, and wiring to power and operate the crane, รถเข็น, และรอก.

Overload limiters, travel limit switches, emergency stop systems, and anti-sway devices to ensure safe operation.

ไตรมาสที่ 1: What’s the difference between a double girder and single girder overhead crane?

ก: Double girder cranes have two main girders, offering higher load capacity (10+ ตัน) and stability, making them suitable for heavy-duty use. Single girder cranes have one main girder, are lighter, and better for lighter loads (ขึ้นไป 10 ตัน) in smaller workspaces.

ไตรมาสที่ 2: Which industries use double girder overhead cranes?

ก: They are widely used in steel mills, automotive manufacturing, อู่ต่อเรือ, สถานที่ก่อสร้าง, คลังสินค้า (for heavy pallet handling), and power plants.

ไตรมาสที่ 3: How often should a double girder overhead crane be maintained?

ก: Routine inspections (daily checks for wear, การหล่อลื่น) and professional maintenance (every 6–12 months) are recommended to ensure safety and longevity.

ไตรมาสที่ 4: Can double girder cranes be customized for specific applications?

ก: ใช่. We offer customizations for load capacity, ช่วง, ยกสูง, ระบบควบคุม, and specialized attachments (เช่น, magnets for metal handling, grabs for bulk materials).

คำถามที่ 5: Are double girder overhead cranes compliant with international safety standards?

ก: Our cranes meet ISO, หญิงสาว, and OSHA standards, with built-in safety features to ensure compliance with global industrial regulations.

แบ่งปันด้วย PDF: ดาวน์โหลด

เราให้ความสำคัญกับความคิดเห็นของคุณ! กรุณากรอกแบบฟอร์มด้านล่างเพื่อให้เราสามารถปรับแต่งบริการของเราให้ตรงกับความต้องการเฉพาะของคุณ.

ที่ 7 เครนเหนือศีรษะตันเป็นอุปกรณ์ขนถ่ายวัสดุอเนกประสงค์และขาดไม่ได้……

ค้นพบเพิ่มเติม →

As a core lifting equipment specially designed for the electrolytic aluminum production……

ค้นพบเพิ่มเติม →

What is an Electric Single Girder Crane? electric single girder crane with electric ho……

ค้นพบเพิ่มเติม →

ความคิดเห็นล่าสุด