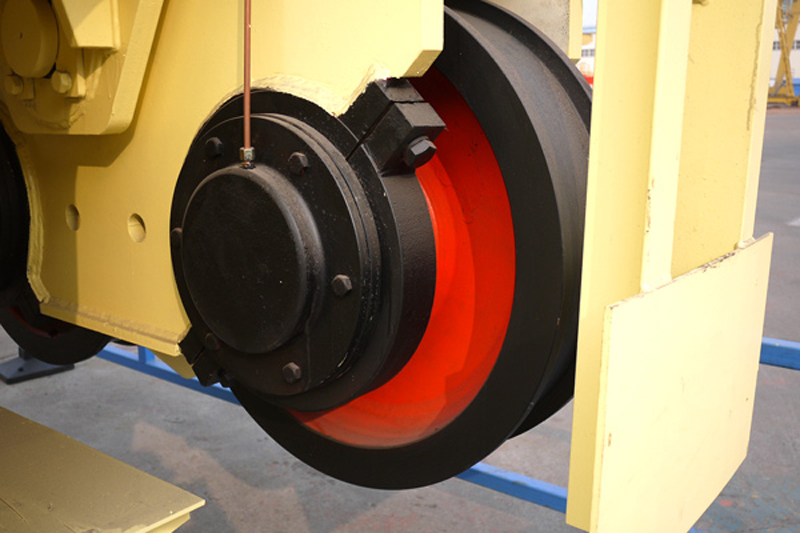

Точкови порталних кранова су критични, компоненте високе прецизности које чине основни интерфејс између порталне дизалице и његове шине на писти.

Точкови порталних кранова су одговорни за ношење целокупног оптерећења дизалице, укључујући и подигнуте материјале, и олакшавање глатке, сеф, и ефикасно уздужно кретање по дефинисаној путањи. Дизајниран за екстремну издржљивост и перформансе, ови точкови директно утичу на радну безбедност дизалице, дуговечност, и нивоа буке. Произведено од легура високе чврстоће и подвргнуто ригорозној термичкој обради, наши точкови порталних кранова су дизајнирани да издрже огроман притисак, ударна оптерећења, и абразивно хабање у најзахтевнијим индустријским окружењима, од челичана и бродских лука до радионица за тешке фабрикације.

1. Изузетна издржљивост & Отпорност на хабање

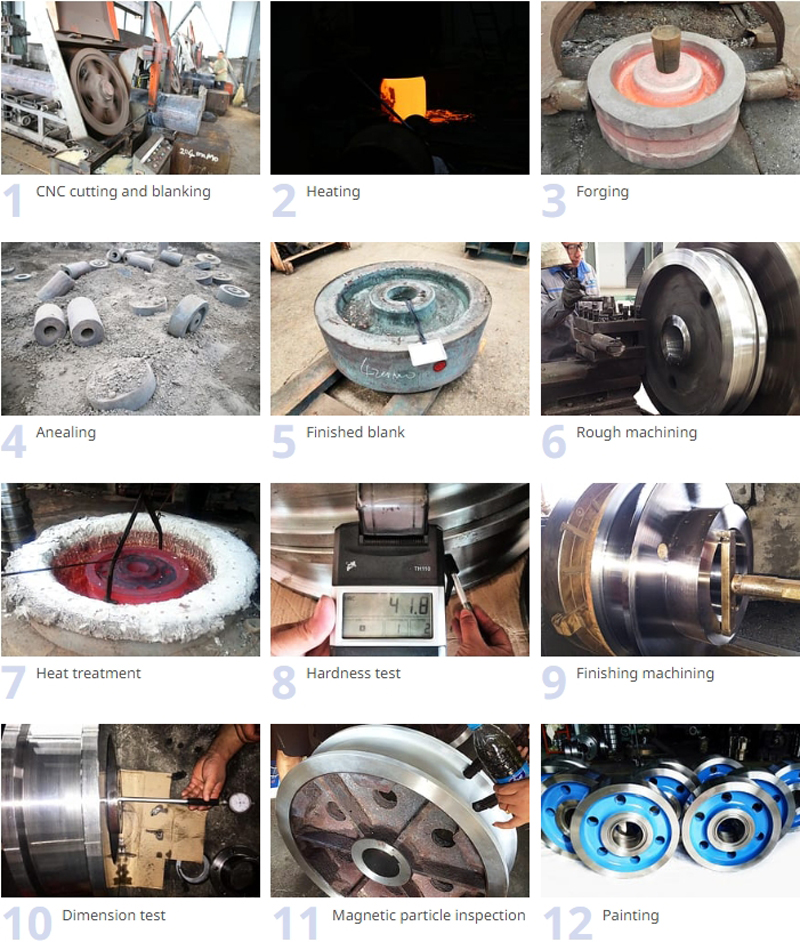

Кован од челика са високим садржајем угљеника или легираног челика (Нпр., 65Мн, 42ЦрМо), наши точкови нуде супериорну затезну чврстоћу и тврдоћу.

Напредни процеси топлотне обраде као што су гашење и каљење стварају тврду, спољна површина отпорна на хабање (обод) уз одржавање чврсте, језгро које апсорбује ударце.

2. Висока носивост

Прецизно конструисан да поднесе статичка и динамичка оптерећења, обезбеђивање стабилних перформанси под пуним називним капацитетом дизалице без деформације.

3. Оптимизовани профил газећег слоја & Дизајн прирубнице

Профил газећег слоја је машински обрађен да савршено одговара контури кранске шине (Нпр., КУПУЈЕМО, КРУПП, равна шина), обезбеђивање максималне контактне површине и смањење напрезања у тачки.

Прирубница је дизајнирана да обезбеди сигурно вођење, спречавање исклизнућа из шина уз минимализовање трења и хабања на страни шине.

4. Прецизна обрада

Сваки точак се подвргава прецизној машинској обради и брушењу како би се постигле строге толеранције пречника, концентричност, и завршну обраду површине. Ово обезбеђује глатку ротацију, смањује вибрације, и продужава животни век и точка и шине.

5. Робусна лежишта

Отвор и утор за кључ су прецизно обрађени како би се осигурало савршено пристајање са осовином и лежајевима, гарантујући ефикасан пренос снаге и спречавање клизања или превременог квара.

6. Опције прилагођавања

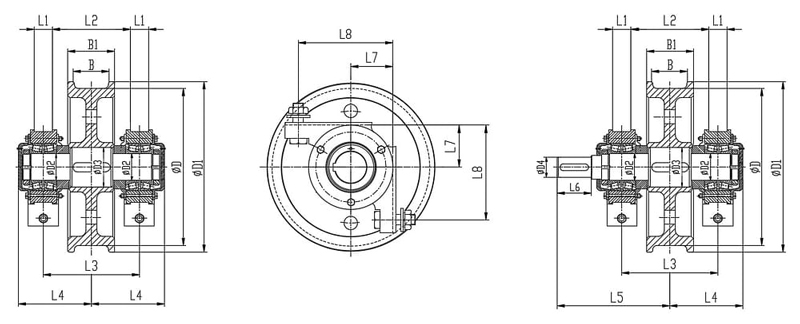

Пружамо потпуно прилагодљиве точкове прилагођене вашим специфичним захтевима, укључујући пречник, ширина, величина отвора, висина прирубнице, и квалитет материјала који одговара вашем јединственом моделу порталне дизалице и примени.

Следећа табела даје стандардне спецификације. Прилагођене димензије и материјали су доступни на захтев.

| Параметар | Спецификација Опсег | Белешке |

|---|---|---|

| Вхеел Диаметер | 250 – 1000+мм | Доступни прилагођени пречници |

| Ширина газећег слоја | 90 – 200+мм | Усклађен са ширином главе шине |

| Пречник отвора | 80 – 200+мм | Прецизно обрађено са утором за кључеве |

| Висина прирубнице | 25 – 45 мм | Стандардно или по захтеву |

| Материал Граде | 65Мн, 42ЦрМо, 55# Челик, Ц45 | Доступни су и други легирани челици |

| Површинска тврдоћа | 45 - 60 ХРЦ | Постиже се топлотном обрадом |

| Тврдоћа језгра | 240 - 280 ХБ | Обезбеђује чврстину и отпорност на ударце |

| Макс. Оптерећење на точковима | 5 - 100+ Тона | По точку, зависно од конфигурације |

Точкови порталних кранова су категорисани на основу њиховог типа прирубнице и материјала/конструкције.

1. Двоструки прирубнички точкови:

2. Точкови са једном прирубницом:

3. Флангелесс Вхеелс:

1. Ковани челични точкови:

Произведено кроз процес ковања који поравнава структуру зрна, што резултира супериорном снагом, отпорност на удар, и живот умора. Они су врхунски избор за тешке услове рада и апликације великог циклуса.

2. Ливени челични точкови:

Направљен је изливањем растопљеног челика у калуп. Исплативо решење за стандардне апликације. Квалитет у великој мери зависи од процеса ливења како би се избегли унутрашњи дефекти.

3. Точкови од легуре челика:

Направљен од челичних легура попут 42ЦрМо или 65Мн, који обезбеђују одличан баланс високе површинске тврдоће и дубоке жилавости након термичке обраде. Ово је најчешћи и препоручени материјал за индустријске порталне дизалице.

4. Учвршћени точкови:

Подвргнути специфичној топлотној обради (Нпр., карбуризација) да створи изузетно тешко, површински слој отпоран на хабање уз задржавање меког, дуктилно језгро. Одличан за апликације са веома високим хабањем и замором од котрљања.

К1: Која је примарна функција точка порталне дизалице?

А: Точак порталне дизалице је основна компонента која служи две главне сврхе: да издрже пуну тежину (оптеретити) порталне дизалице и њених дизаних материјала, и да несметано и безбедно води кран дуж шина писте.

К2: Колико често треба прегледати точкове порталне дизалице?

А: Препоручујемо визуелну инспекцију пре сваке смене да ли има знакова хабања, пукотина, или оштећења. Формално, квалификовани техничар треба да спроводи детаљну инспекцију месечно. Тачна фреквенција зависи од радног циклуса дизалице, интензитет оптерећења, и радно окружење.

К3: Који су уобичајени знаци квара кранског точка?

А: Уобичајени знаци упозорења укључују:

К4: Како да изаберем прави материјал за точак крана?

А: Избор зависи од захтева ваше апликације:

К6: Како се израчунава максимално оптерећење точкова?

А: Максимално оптерећење точка је израчуната вредност на основу укупне тежине дизалице, његов капацитет дизања, број точкова, и расподела оптерећења. То је критичан безбедносни параметар. Наш инжењерски тим може помоћи у верификацији потребне носивости точкова за ваш систем.

Све наведене спецификације и подаци су у референтне сврхе. Коначан дизајн и спецификације морају бити потврђени на основу специфичног модела порталне дизалице, дежурна класа, и услове рада. Контактирајте наш инжењерски тим за решење по мери.

Ценимо ваше повратне информације! Молимо испуните доњи образац како бисмо прилагодили наше услуге на ваше специфичне потребе.

WEIHUA Single Girder Gantry Crane: High-Efficiency Lifting Solution for Industrial Appl……

Откријте више →

Introduction to Weihua 32 Tons Overhead Crane Weihua 32 tons overhead crane is a high-……

Откријте више →

У захтевном свету руковања материјалом, изградња, и дизање тешких терета, сваки комп....

Откријте више →

Кликните на дугме да бисте добили информације и цитати производа на ВхатсАпп-у.

Набавити цитат

Најновији коментари