Мостовые краны — рабочие лошадки на производственных предприятиях, строительные площадки, и склады, играет решающую роль в подъеме и перемещении тяжелых грузов. Однако, их безопасная и эффективная работа во многом зависит от регулярных и тщательных проверок.. Пренебрежение проверками может привести к выходу оборудования из строя., несчастные случаи на производстве, и дорогостоящие простои. В этом блоге, мы покажем вам пошаговое руководство, как правильно осмотреть мостовой кран.

Предпроверочная подготовка

Прежде чем начать проверку, Правильная подготовка необходима для обеспечения безопасности и эффективности процесса..

- 1. Просмотреть документацию: Соберите инструкцию по эксплуатации крана., записи о техническом обслуживании, и предыдущие отчеты о проверках. Это поможет вам понять историю крана., любые прошлые проблемы, и особые требования к проверке.

- 2. Подготовьте инструменты и оборудование: Вооружитесь необходимыми инструментами, такими как фонарик., измерительная лента, динамометрический ключ, инспекционное зеркало, и камера для документирования результатов. Также, убедитесь, что у вас есть средства индивидуальной защиты (Ст) как каска, защитная обувь, перчатки, и страховочная привязь при работе на высоте.

- 3. Охрана территории: Заблокируйте зону вокруг крана, чтобы предотвратить несанкционированный доступ.. Установите предупреждающие знаки и убедитесь, что во время проверки никто не работает и не проходит под краном..

- 4. Проверьте источник питания: Убедитесь, что питание крана отключено и заблокировано/маркировано. (Сердце) во избежание случайного включения во время проверки.

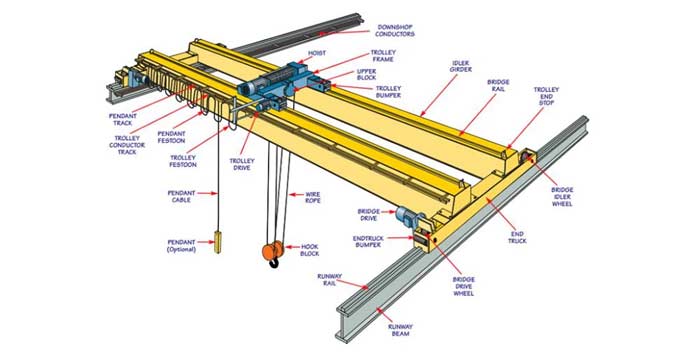

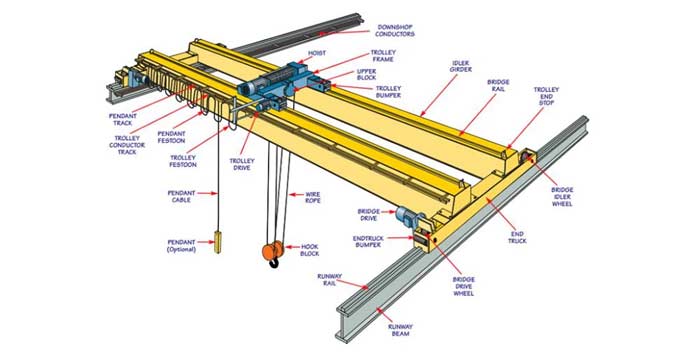

Визуальный осмотр ключевых компонентов

Детальный визуальный осмотр является основой осмотра крана.. Сосредоточьтесь на следующих важнейших компонентах:

1. Подъемная система

Подъемная система

- Крюк мостового крана: Проверьте наличие трещин, деформация, носить на крючке горловину или хвостовик, и повреждение защелки. Убедитесь, что крюк свободно вращается, а защелка работает правильно, чтобы предотвратить соскальзывание груза..

- Проволочный канат: Осмотрите провода на наличие обрывов, перегибы, коррозия, носить, и неправильная смазка. Обратите внимание на участки рядом с барабаном и шкивами, где износ наиболее распространен.. Измерьте диаметр каната, чтобы проверить его на чрезмерный износ (если он ниже рекомендованного производителем предела)., заменить веревку.

- Барабан и шкивы: Ищите трещины, износ фланца барабана или канавок шкива, и перекос. Обеспечить крановый тросовый барабан не поврежден, веревка правильно сидит в пазах, не перехлестываясь.

- Тормозная система: Проверьте тормозные колодки на износ, правильная регулировка, и загрязнение (масло или пыль). Проверьте работу тормоза, чтобы убедиться, что он надежно удерживает номинальную нагрузку..

2. Мост и троллейбус

тележка

- Мостовая балка: Осмотрите балку моста на наличие трещин, изгиб, или искажение. Проверьте соединения между балкой и концевыми тележками на герметичность и наличие признаков износа..

- Тележка: Осмотрите колеса тележки на предмет износа., трещины, и правильное выравнивание. Проверка механизма привода тележки, включая шестерни и подшипники, за необычный шум или повреждение.

- Рельсы взлетно-посадочной полосы: Проверьте рельсы взлетно-посадочной полосы на предмет прямолинейности., ровность, и носить. Ищите ослабленные крепления, поврежденные рельсовые стыки, и мусор на рельсах, который может помешать движению крана.

3. Электрическая система

радиоуправление краном

- Кабели и провода: Проверьте кабели на предмет изношенности, свободные соединения, и повреждена изоляция. Убедитесь, что кабели правильно поддерживаются, не тянутся и не трутся о другие компоненты..

- Панель управления: Осмотрите панель управления на наличие признаков перегрева., коррозия, или повреждение водой. Проверьте кнопки, переключатели, и индикаторы, чтобы убедиться, что они работают правильно.

- Концевые выключатели: Проверьте работу верхних и нижних концевых выключателей подъемника., а также концевые выключатели хода моста и тележки. Эти переключатели предотвращают выход крана за пределы безопасных пределов..

Эксплуатационные испытания

После визуального осмотра, провести эксплуатационные испытания, чтобы убедиться в правильной работе крана под нагрузкой (если применимо) и в условиях холостого хода.

- 1. Тест без нагрузки: Включите питание и проверьте подъемник., мост, и движения троллейбусов во всех направлениях. Проверьте плавность работы, необычные шумы, и правильное торможение. Убедитесь, что концевые выключатели активируются, когда кран достигает безопасных пределов..

- 2. Нагрузочный тест: Проведите нагрузочное испытание, используя тестовую нагрузку, которая 100% к 125% номинальной грузоподъемности крана (следуйте рекомендациям производителя). Медленно поднимите груз, переместите его горизонтально, и опусти его. Следите за любым чрезмерным прогибом балки моста., необычные шумы от компонентов, или проблемы с тормозной системой. Убедитесь, что нагрузка остается стабильной на протяжении всего испытания..

- 3. Послетестовые проверки: После завершения эксплуатационных испытаний, отключите питание и выполните окончательную визуальную проверку ключевых компонентов, чтобы убедиться, что во время тестирования не возникло новых проблем.. Проверьте, нет ли ослабленных креплений или признаков напряжения, которое могло возникнуть..

Документация и последующие действия

Тщательная документация и своевременный контроль необходимы для поддержания показателей безопасности крана и оперативного решения проблем.. Пропуск этого шага может привести к упущению из виду проблем, которые перерастут в серьезные опасности..

- 1. Запишите детали проверки: Документируйте каждый аспект проверки, включая дату, имя инспектора, идентификационный номер крана, и полный список проверенных компонентов. Для каждого компонента, обратите внимание на его состояние — в хорошем ли он состоянии, показывает незначительный износ, или имеет критические дефекты. Прикрепите фотографии или видео проблемных мест для наглядного доказательства..

- 2. Классифицируйте дефекты по серьезности: Классифицировать дефекты, чтобы определить приоритетность ремонта.: – Критический: Дефекты, представляющие непосредственную опасность (НАПРИМЕР., треснувший крючок, сломанные тросы). Кран должен быть немедленно выведен из эксплуатации до завершения и проверки ремонта.. - Главный: Проблемы, которые могут стать критическими в ближайшее время (НАПРИМЕР., изношенные тормозные колодки толщиной ниже рекомендованной). Запланируйте ремонт в сжатые сроки, и при необходимости ограничить использование крана. - Незначительный: Косметические повреждения или незначительный износ, не влияющий на безопасность. (НАПРИМЕР., незначительные сколы краски). Устраните эти проблемы во время планового технического обслуживания..

- 3. Обновление журналов обслуживания: Интегрируйте отчет об осмотре в официальный журнал технического обслуживания крана.. Этот журнал должен отслеживать все проверки., ремонт, замены, и графики смазки. Он служит исторической записью для будущих проверок и помогает выявить повторяющиеся проблемы..

- 4. Общайтесь и назначайте действия: Поделитесь отчетом об инспекции с соответствующими заинтересованными сторонами, включая ремонтные бригады, супервайзеры, и крановщики. Четко распределите обязанности по устранению дефектов — укажите, кто будет выполнять эту работу., когда оно будет завершено, и как это будет проверено. Следите за тем, чтобы все действия выполнялись по плану..

Как часто нужно проверять мостовые краны?

Частота проверок мостового крана зависит от его использования., среда, и нормативные требования. Вот общие рекомендации:

- 1. Ежедневные проверки: Проводится оператором перед каждой сменой. Проверьте наличие очевидных проблем, таких как поврежденные крючки., свободные кабели, или посторонние шумы во время запуска.

- 2. Ежемесячные/ежеквартальные проверки: Выполняется обслуживающим персоналом. Включите более детальную визуальную проверку и базовые эксплуатационные тесты..

- 3. Ежегодные проверки: Комплексные проверки квалифицированными инспекторами (сертифицировано соответствующими органами). Сюда входит нагрузочное тестирование, подробные измерения компонентов, и диагностика электросистемы.

- 4. После капитального ремонта или аварии: Тщательно осмотрите кран после любого значительного ремонта., модификации, или инциденты (НАПРИМЕР., перегрузка, столкновение) чтобы убедиться в безопасности работы.

Заключение

Осмотр мостового крана – это систематический процесс, сочетающий в себе подготовку, визуальные проверки, эксплуатационные испытания, документация, и последующие действия. Следуя этому руководству, вы не только соблюдаете правила техники безопасности, но и защитите свой персонал от несчастных случаев и продлите срок службы крана. Помнить, безопасность никогда не должна ставиться под угрозу: регулярные проверки являются инвестицией в предотвращение дорогостоящих простоев и трагических инцидентов.. Если вы не уверены в каком-либо аспекте проверки, обратитесь за советом к квалифицированному инспектору кранов или к производителю..

Часто задаваемые вопросы о контрольном списке проверки мостового крана

1 квартал: Какие ключевые разделы обычно включаются в контрольный список проверки мостового крана??

А: Стандартный контрольный список охватывает предпроверочную подготовку. (рассмотрение документации, подготовка инструмента/СИЗ, охрана территории, Сердце), визуальный осмотр основных компонентов (подъемная система, мост/троллейбус, электрическая система), эксплуатационные испытания (без нагрузки, нагрузка, послетестовые проверки), и документация/последующие действия (запись результатов, классификация дефектов, обновления журнала обслуживания).

2 квартал: Чем отличается частота проверок для ежедневных и. ежегодные проверки в чек-листе?

А: Ежедневные проверки (по операторам) сосредоточьтесь на очевидных проблемах, таких как поврежденные крючки., свободные кабели, или шум при запуске. Ежегодные проверки (квалифицированными инспекторами) являются всеобъемлющими, включая нагрузочное тестирование (100%-125% номинальная мощность), подробные измерения компонентов, и электрическая диагностика — оба являются обязательными в большинстве контрольных списков для обеспечения краткосрочной и долгосрочной безопасности..

Q3: Кто несет ответственность за заполнение контрольного списка проверки мостового крана?

А: Ежедневные контрольные списки заполняются крановщиком перед каждой сменой.. Ежемесячные/ежеквартальные контрольные списки обрабатываются обслуживающим персоналом.. Ежегодные и послеремонтные контрольные листы должны заполняться сертифицированными квалифицированными инспекторами. (согласно OSHA или местным нормативным стандартам) чтобы обеспечить соблюдение.

Q4: Почему классификация дефектов важна в контрольном списке проверки?

А: Классификация дефектов (критический, главный, незначительный) в контрольном списке помогает расставить приоритеты действий. Критические дефекты (НАПРИМЕР., треснувшие крючки) требуют немедленного выключения; основные проблемы (НАПРИМЕР., изношенные тормозные колодки) нужен срочный ремонт; второстепенные (НАПРИМЕР., сколы краски) перейти к плановому техническому обслуживанию. Это предотвращает упущенные из виду опасности и оптимизирует рабочие процессы ремонта..

Q5: Можно ли адаптировать контрольный список для разных типов мостовых кранов??

А: Да. Хотя основные разделы универсальны, контрольные списки должны быть адаптированы к типам кранов (НАПРИМЕР., мостовые краны, Гарновые краны) и сценарии использования (сверхмощный против. легкий). Например, Контрольный список портового козлового крана может включать дополнительные проверки компонентов, устойчивых к атмосферным воздействиям., в то время как складской мостовой кран может подчеркнуть выравнивание взлетно-посадочной полосы.

Последние комментарии