Weihua forklift crane hook adopts a quick connector system, which is suitable for mainstream brand forklifts and can be installed quickly. The hook body adopts alloy steel one-piece forging technology to improve the tensile strength of the hook. Meet various lifting needs under different working conditions.

Na logística de armazenamento, manutenção de equipamentos ou cenários de elevação temporária, traditional cranes are often costly and lack maneuverability. Weihua’s innovatively designed forklift crane hook (special levantando o gancho de guindaste for forklifts) allows standard forklifts to be upgraded to mobile mini-cranes in 3 segundos! Through the perfect combination of high-strength hook components and intelligent safety locks, we provide you with a low-cost, highly flexible heavy object lifting solution.

Patented quick connector system:

Suitable for mainstream brand forklifts.

No tools required, one person can complete hook/fork switching in 3 segundos.

Modification-free design: directly utilize the existing hydraulic attachment interface of the forklift to retain the original vehicle load capacity.

One-piece forged hook body:

Material: Aisi 4140 liga de aço (tensile strength ≥1200 MPa).

Safety factor ≥5:1, far exceeding ISO 10535 padrão.

Triple insurance mechanism: Mechanical self-locking tongue (anti-decoupling); Dual redundant safety pins (to prevent accidental unlocking); Overload alarm module (opcional, 110% load whistle).

Certificação CE + ISO 10535 Relatório de teste: third-party certificate provided with goods.

Low headroom compact type: the distance from hook tip to fork frame is ≤200mm (standard fork position), maximizing the use of lifting height.

360° rotating bearing: the load direction can be manually adjusted during hoisting to avoid rope entanglement.

Modular expansion interface: can be installed:

Electronic scale (accuracy ±0.5%).

Double hook balancing beam (asymmetrical loading).

Magnetic chuck (steel plate lifting).

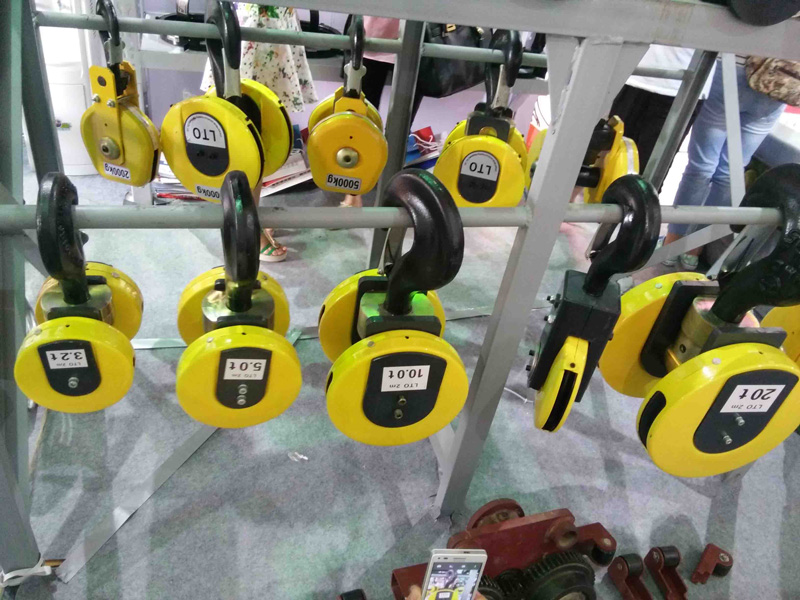

| Modelo | Carga de trabalho segura | Applicable forklift tonnage | Hook width | Featured scenes |

| WH-FH1 | 1 tonelada | 1.5~3t | 60mm | Warehouse equipment maintenance |

| WH-FH3 | 3 tonelada | 3~5t | 80mm | Mold/mechanical component lifting |

| WH-FH5 | 5 tonelada | 5~8t | 100mm | Small container unpacking |

| WH-FH10 | 10 tonelada | 10t+ | 150mm | Factory equipment installation |

Surface strengthening process:

Shot peening (anti-fatigue) + galvanização a quente (anti-corrosion).

Optional stainless steel version (food/chemical industry).

Self-lubricating bearings: 10,000 hours maintenance-free.

Container cargo unpacking operation

Pain point: Large equipment cannot be taken out with forks, and the cost of hiring a crane is $500+/hour.

Weihua plan:

WH-FH5 hook + lifting strap.

The forklift drives directly into the container and lifts out the heavy objects.

Cost comparison: save 80% on rental fees.

Quick replacement of production line molds

Pain point: Changing the mold of the injection molding machine requires two people to operate the crane, which takes 30 minutos.

Weihua plan:

WH-FH3 hook + mold special lifting beam.

One person completes air transfer of mold in 5 minutos.

Efficiency improvement: mold change time is reduced by 83%.

Emergency maintenance of outdoor equipment

Pain point: There is no crane in the field, and it is difficult to disassemble and assemble the diesel engine.

Weihua plan:

WH-FH10 hook + anti-sway chain.

The forklift moves to the fault point to lift the component.

Valor: Repair time shortened to 1/4.

| Project | Parameter value |

| Carga nominal | 5,000 kg |

| Test load | 7,500 kg (1.5×SWL) |

| Self-respect | 78 kg |

| Suitable forklift lifting capacity | ≥ 5,000 kg |

| Maximum hook width | 100 mm |

| Ângulo de rotação | 360° manual lock |

| Temperatura de trabalho | -30℃ ~ +80℃ |

| Security certification | CE, ISO 10535, GB/T 10051.1 |

P:Can the forklift crane hook be used as an ordinary fork?

UM:cannot! This is an accessory specially designed for lifting. It is necessary to switch to the fork mode for pallet handling, and the switching time only takes 3 segundos.

P:How do I confirm if my forklift can be installed?

UM:Just provide: ① forklift model ② photo of attachment interface ③ hydraulic pressure value.

Weihua engineers will provide feedback on compatibility reports within 24 horas.

P:How to control the center of gravity of the forklift during lifting?

UM:Must comply with:

① The load is always directly in front of the fork.

② Lifting height ≤ 1/2 of vehicle height.

③ Install Weihua balance stabilizer (opcional).

Valorizamos seu feedback! Preencha o formulário abaixo para que possamos adaptar nossos serviços às suas necessidades específicas.

Construído para suportar a fúria do forno Os ganchos de guindaste metalúrgicos de Weihua são ...

Descubra mais →

Projetado para desempenho e segurança Materiais Premium & Forjamento: Guindaste Weihua EOT ......

Descubra mais →

Gama de produtos principais Correntes de elevação de liga de aço Notas: Fabricado para G80 (Nota 8) um……

Descubra mais →

Clique no botão para obter informações e citações do produto no WhatsApp.

Obtenha cotação

Últimos comentários