Suwnica dwudźwigarowa to solidny sprzęt do transportu materiałów przeznaczony do podnoszenia i transportu ciężkich ładunków w warunkach przemysłowych.

Suwnica dwudźwigarowa to solidny sprzęt do transportu materiałów przeznaczony do podnoszenia i transportu ciężkich ładunków w warunkach przemysłowych. Zaprojektowane z dwoma równoległymi dźwigarami głównymi, zapewnia doskonałą stabilność i nośność w porównaniu do modeli jednodźwigarowych, dzięki czemu jest to doskonały wybór do zastosowań wymagających dużych obciążeń, takich jak huty stali, zakłady produkcyjne, magazyny, i placów budowy. Niezależnie od tego, czy potrzebujesz przenieść maszyny, surowce, lub gotowe produkty, nasze suwnice dwudźwigarowe łączą w sobie precyzję, trwałość, i bezpieczeństwo, aby zoptymalizować przepływ pracy.

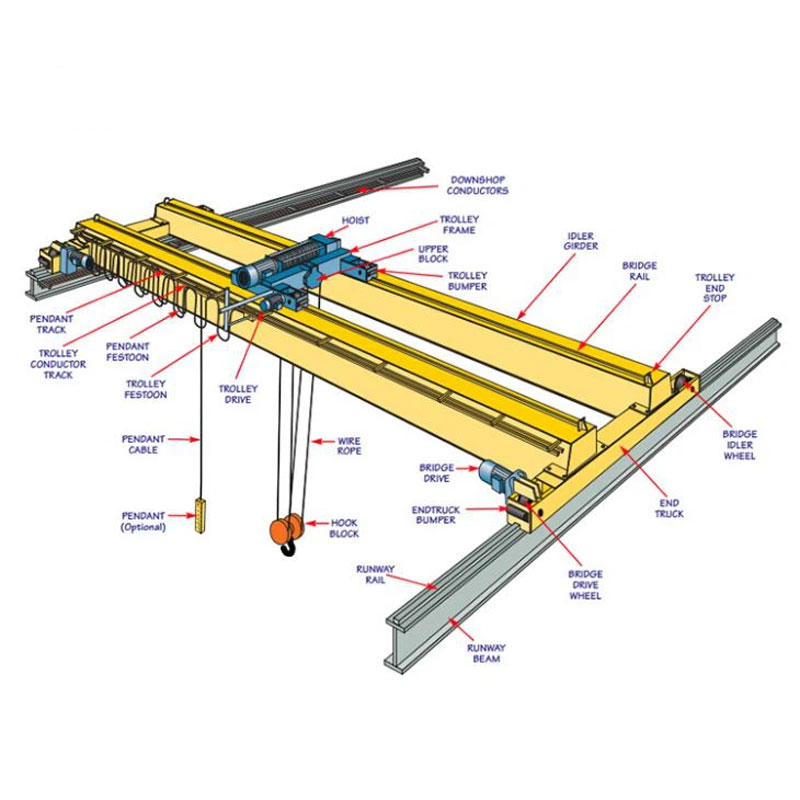

Suwnica dwudźwigarowa to rodzaj suwnicy pomostowej składającej się z dwóch poziomych dźwigarów głównych wspartych na wózkach końcowych (lub wagony końcowe) które biegną po podwyższonych szynach (pasy startowe) montowane na słupach budynków lub konstrukcjach wolnostojących. Mechanizm podnoszący dźwigu — zwykle wciągnik lub wózek — jest zamontowany na wózku poruszającym się wzdłuż głównych dźwigarów, umożliwiając pokrycie obszaru roboczego poniżej w zakresie 360°.

Inaczej suwnice jednodźwigarowe, które opierają się na jednej belce głównej, konstrukcje z podwójnymi dźwigarami rozkładają ciężar bardziej równomiernie, dzięki czemu są w stanie wytrzymać znacznie większe obciążenia (często do 500 ton lub więcej). To sprawia, że są niezbędne w branżach wymagających częstego podnoszenia ciężkich przedmiotów, gdzie niezawodność i bezpieczeństwo nie podlegają negocjacjom.

Nasze suwnice dwudźwigarowe są zbudowane tak, aby doskonale sprawdzały się w wymagających środowiskach. Oto ich wyjątkowe cechy:

|

Parametr

|

Zakres/Szczegóły

|

|

Maksymalny udźwig

|

10 tony – 500 mnóstwo (dostępne opcje niestandardowe dla większych obciążeń)

|

|

Długość rozpiętości

|

10m – 35m (niestandardowe rozpiętości na zamówienie)

|

|

Wysokość podnoszenia

|

6m – 30 m (regulowane w zależności od zastosowania)

|

|

Prędkość podnoszenia

|

0.5m/min – 10 m/min (zmienna prędkość z opcją przetwornicy częstotliwości)

|

|

Prędkość jazdy wózka

|

5m/min – 30 m/min

|

|

Prędkość jazdy żurawia

|

10m/min – 50 m/min

|

|

Klasa robotnicza

|

A5 – A8 (Standard ISO; nadaje się do zastosowań lekkich i ciężkich, ciągłe użytkowanie)

|

|

Zasilacz

|

380V/3 fazy/50 Hz (Możliwość dostosowania do napięcia 220 V/440 V lub innych regionów)

|

|

Tryb sterowania

|

Sterowanie wisiorkiem, zdalne sterowanie (bezprzewodowy), lub sterowanie kabiną

|

Suwnica dwudźwigarowa składa się z kilku kluczowych elementów współpracujących ze sobą w celu zapewnienia wydajnego podnoszenia i przemieszczania:

Główne dźwigary

Dwie równoległe belki stalowe (dźwigary) które tworzą konstrukcję mostu. Unoszą ciężar wózka i podnoszonego materiału, wymagających dużej wytrzymałości i sztywności.

Ciężarówki końcowe

Montowane na obu końcach dźwigarów głównych, mieszczą się w nich koła i silniki napędzające dźwig po szynach pasa startowego.

Wózek

Ruchoma jednostka poruszająca się po górze lub dole głównych dźwigarów. Utrzymuje wciągnik i jest napędzany własnym silnikiem do ruchu poziomego.

Wciągnik

Mechanizm podnoszący, w tym: bęben dźwigu, lina stalowa/kabel, I Haczyk dźwigu. Odpowiada za podnoszenie i opuszczanie ładunków, z możliwością sterowania elektrycznego lub hydraulicznego.

Układ elektryczny

Zawiera silniki, panele sterujące, przełączniki, oraz okablowanie do zasilania i obsługi dźwigu, wózek, i podnośnik.

Ogranicznik wysokości podnoszenia

Ograniczniki przeciążenia, wyłączniki krańcowe jazdy, systemy zatrzymania awaryjnego, oraz urządzenia zapobiegające kołysaniu, zapewniające bezpieczną pracę.

Q1: Jaka jest różnica między suwnicą dwudźwigarową a suwnicą jednodźwigarową?

A: Suwnice dwudźwigarowe mają dwa główne dźwigary, oferując większą ładowność (10+ mnóstwo) i stabilność, dzięki czemu nadają się do intensywnego użytkowania. Żurawie jednodźwigarowe mają jeden dźwigar główny, są lżejsze, i lepiej dla lżejszych ładunków (aż do 10 mnóstwo) w mniejszych przestrzeniach roboczych.

Q2: W jakich branżach stosuje się suwnice dwudźwigarowe?

A: Są szeroko stosowane w hutach stali, produkcja samochodów, stoczni, place budowy, magazyny (do przenoszenia ciężkich palet), i elektrownie.

Q3: Jak często należy konserwować suwnicę dwudźwigarową?

A: Rutynowe kontrole (codzienna kontrola zużycia, smarowanie) i profesjonalną konserwację (co 6–12 miesięcy) są zalecane ze względu na bezpieczeństwo i długowieczność.

Q4: Czy suwnice dwudźwigarowe można dostosować do konkretnych zastosowań?

A: Tak. Oferujemy dostosowania pod względem ładowności, przęsło, wysokość podnoszenia, systemy sterowania, i specjalistyczne załączniki (NP., magnesy do przenoszenia metali, chwytaki do materiałów sypkich).

Q5: Czy suwnice dwudźwigarowe spełniają międzynarodowe standardy bezpieczeństwa?

A: Nasze dźwigi spełniają wymagania ISO, Fem, i standardy OSHA, z wbudowanymi funkcjami bezpieczeństwa zapewniającymi zgodność ze światowymi przepisami przemysłowymi.

Udostępnij w formacie PDF: Pobierać

Cenimy twoją opinię! Wypełnij poniższy formularz, abyśmy mogli dostosować nasze usługi do twoich konkretnych potrzeb.

30 Suwnica tonowa: Rozwiązanie do transportu materiałów o dużej wytrzymałości The 30 ton ładunku napowietrznego......

Odkryj więcej →

Bęben linowy dźwigu służy jako rdzeń mechanizmu podnoszącego i, w niektórych przypadkach, trawersy……

Odkryj więcej →

Introduction to Single Girder Overhead Crane A single girder overhead crane is a versa……

Odkryj więcej →

Kliknij przycisk, aby uzyskać informacje o produkcie i cytaty na WhatsApp.

Zdobądź wycenę

Najnowsze komentarze