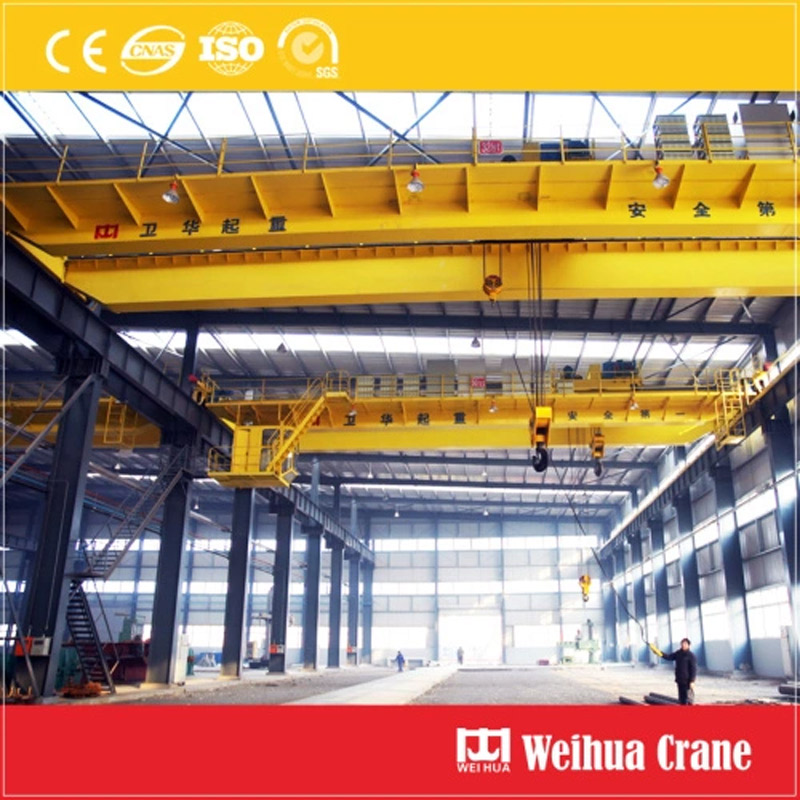

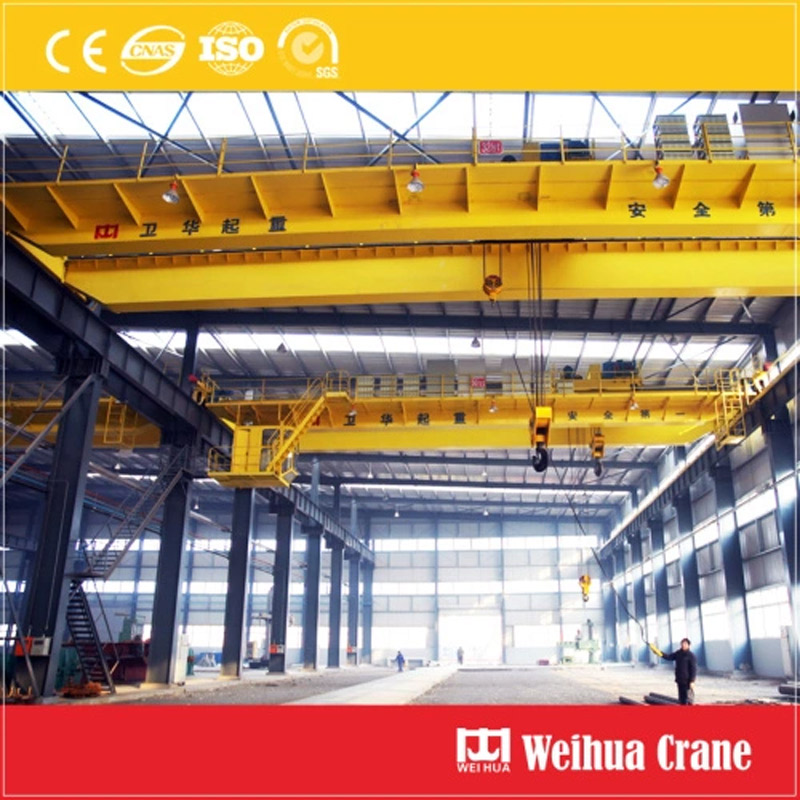

Nasz 80 tons overhead crane is a bridge-type lifting device installed on the upper part of industrial workshops, magazyny, or open-air yards. It consists of a bridge frame, wózek, mechanizm podnoszący, traveling mechanism, electrical control system, and safety protection devices. With a rated lifting capacity of 80 mnóstwo, it can efficiently lift, przenosić, and place heavy materials within the working range, significantly improving production efficiency and reducing labor intensity. The crane adopts a modular design, facilitating installation, konserwacja, and future upgrades.

Dlaczego warto wybrać nasze 80 Suwnica tonowa? Key Applications of 80 Suwnica tonowa

Nasz 80 ton overhead crane is tailored to address the unique lifting needs of multiple heavy industries. Its robust design and high load-bearing capacity make it an ideal solution for scenarios where precision and durability are non-negotiable. Typical applications include:

- 1. Stal & Metallurgy Industry: Efficiently handling steel ingots, hot-rolled plates, cewki stalowe, and finished steel products in steel mills and metallurgical processing facilities. The crane’s high-temperature resistance (fakultatywny) and stable operation ensure safe handling even in harsh, high-heat environments.

- 2. Produkcja maszyn ciężkich: Assembling and moving large machinery parts such as engine blocks, obudowy turbin, and machine tool bases. Precise positioning capabilities minimize assembly errors and improve production efficiency.

- 3. Power Generation Industry: Installing and maintaining heavy equipment in thermal power plants, hydropower stations, and nuclear power facilities—including boilers, generatory, and turbines. Strict safety compliance meets the industry’s stringent regulatory requirements.

- 4. Port & Maritime Industry: Loading and unloading heavy cargo, ship components, and containers at ports, doki, and shipyards. The crane’s long-span design (Dostosowywanie) adapts to large open-air working areas.

- 5. Górnictwo & Budowa: Handling large mining equipment, mineral ore, and prefabricated construction components (NP., konstrukcje stalowe, belki betonowe) in mines and large-scale construction sites. Dust-proof and anti-corrosion options ensure durability in harsh outdoor conditions.

Core Advantages of 80 Suwnica tonowa: Built for Performance & Bezpieczeństwo

Every aspect of our 80 ton overhead crane is engineered to deliver superior performance, reduce downtime, and protect your operations. Here’s what sets it apart:

- 1. Uncompromising Load-Bearing Reliability: The crane’s main beam is fabricated from high-grade Q355B structural steel, featuring precision welding and heat treatment processes. This ensures exceptional structural rigidity and load-bearing capacity, enabling stable lifting of 80-ton loads without deformation—even during long-term continuous operation.

- 2. High-Efficiency & Płynna praca: Equipped with variable frequency drive (VFD) technology, the crane offers stepless speed adjustment for both lifting and traveling motions. This allows for precise load positioning, reduces impact on materials and equipment, and lowers operational noise. High-efficiency motors power the hoisting and traveling mechanisms, balancing strong performance with energy savings.

- 3. Kompleksowy System Zabezpieczeń: Multiple redundant safety features are integrated to eliminate operational risks: Ochrona przed przeciążeniem (automatically cuts power when exceeding rated load), upper/lower overtravel limits, anti-collision sensors, przyciski zatrzymania awaryjnego, voltage loss protection, and phase failure protection. All safety components comply with ISO and CE standards, ensuring full regulatory compliance.

- 4. Intelligent & User-Friendly Control: A state-of-the-art PLC (Programowalny kontroler logiki) system centralizes all operational controls, supporting both on-site panel operation and optional remote control. The intuitive control interface features clear indicators and ergonomic buttons, reducing operator training time and minimizing human error.

- 5. Durable & Low-Maintenance Design: Modular construction simplifies installation, konserwacja, and future upgrades. High-quality, wear-resistant components (NP., namiar, koła zębate) and anti-corrosion surface treatment extend the crane’s service life. Routine maintenance points are easily accessible, ograniczenie przestojów i kosztów operacyjnych.

Product Design & Construction of 80 Suwnica tonowa

Nasz 80 ton overhead crane adopts a bridge-type structure, consisting of key components that work in harmony to deliver seamless performance:

- 1. Bridge Frame: Lightweight yet robust design, spanning across the working area to support the trolley and hoisting mechanism. Available in customized spans (10-35M) to fit different workshop or yard dimensions.

- 2. Hoisting Mechanism: High-torque motor paired with a precision gearbox and wire rope system, ensuring stable and efficient load lifting/lowering. Lifting height is customizable (6-30M) to meet specific operational needs.

- 3. Traveling Mechanism: Dual-drive system for the crane bridge and trolley, ensuring smooth movement along rails. Wear-resistant wheels and high-performance brakes guarantee reliable operation even under heavy loads.

- 4. Układ elektryczny: Industrial-grade electrical components from renowned brands, providing stable power supply and control. Equipped with surge protection and waterproof enclosures to adapt to various working environments.

Technical Specifications for 80 Suwnica tonowa

|

Parametr

|

Specyfikacja

|

|

Nominalny udźwig

|

80 Mnóstwo

|

|

Przęsło

|

10 - - 35 M (Możliwość dostosowania)

|

|

Wysokość podnoszenia

|

6 - - 30 M (Możliwość dostosowania)

|

|

Prędkość podnoszenia (Pusty/załadowany)

|

0.8 - - 8 m/my (VFD Stepless Regulation)

|

|

Prędkość jazdy wózka

|

10 - - 30 m/my (VFD Stepless Regulation)

|

|

Prędkość jazdy żurawia

|

20 - - 45 m/my (VFD Stepless Regulation)

|

|

Zasilacz

|

380V/50 Hz/3 fazy (Customizable for Regional Standards)

|

|

Main Beam Material

|

Q355B High-Strength Steel

|

|

Klasa robotnicza

|

A5 – A7 (Customizable for Duty Cycle)

|

|

Całkowita waga

|

Dependent on Custom Specifications

|

Zapewnienie jakości & After-Sales Support for 80 Suwnica tonowa

We are committed to delivering products of the highest quality. Nasz 80 ton overhead crane undergoes rigorous quality control throughout the production process, from raw material inspection to final assembly and testing. Wszystko suwnice are certified by ISO 9001 Quality Management System and CE, ensuring they meet international safety and performance standards. Before delivery, each unit undergoes load testing, testy operacyjne, and safety system verification to guarantee trouble-free operation.

Our comprehensive after-sales service ensures peace of mind for every customer:

- 1. On-site installation and commissioning by certified engineers.

- 2. Free operator and maintenance training to ensure safe and efficient use.

- 3. 24/7 technical support hotline to resolve any operational issues promptly.

- 4. Scheduled maintenance and inspection services to extend equipment lifespan.

- 5. 12-month warranty period (excluding wear parts) from the date of commissioning.

Customized Solutions for Your 80 Tons Overhead Crane Needs

We understand that every industrial operation has unique requirements. Our team of experienced engineers can customize the 80 ton overhead crane to match your specific working conditions, w tym:

- 1. Custom span and lifting height adjustments.

- 2. Wysoka temperatura, dust-proof, or waterproof modifications for harsh environments.

- 3. Advanced anti-sway systems for precise load control.

- 4. Remote monitoring and intelligent management systems for fleet control.

Contact Us for a Tailored Quote

Ready to enhance your heavy-duty material handling operations with our 80 Ton napowietrzny dźwig? Contact our sales team today to discuss your requirements. We will provide a detailed product proposal, customized quotation, and technical consultation within 24 godziny.

Udostępnij w formacie PDF: Pobierać

Najnowsze komentarze