Procedury bezpieczeństwa obsługi suwnic

2025-12-12

Suwnice pomostowe są niezbędnymi końmi pociągowymi w zakładach produkcyjnych, place budowy, magazyny, i węzły logistyczne. These powerful machines streamline heavy lifting tasks, boost productivity, and enable the movement of loads that would otherwise be impossible for manual labor. Jednakże, their immense power and complexity also pose significant safety risks—from load drops and structural failures to collisions and operator injuries—if not operated with strict adherence to safety protocols. Na tym blogu, we’ll break down the essential safety operating procedures for overhead cranes, designed to protect operators, bystanders, sprzęt, and valuable assets.

Pre-Operation Inspection: Lay the Foundation for Safety

Before powering up an suwnica, a thorough pre-operation inspection is non-negotiable. This step identifies potential hazards early, preventing accidents before they occur. Here’s what operators must check:

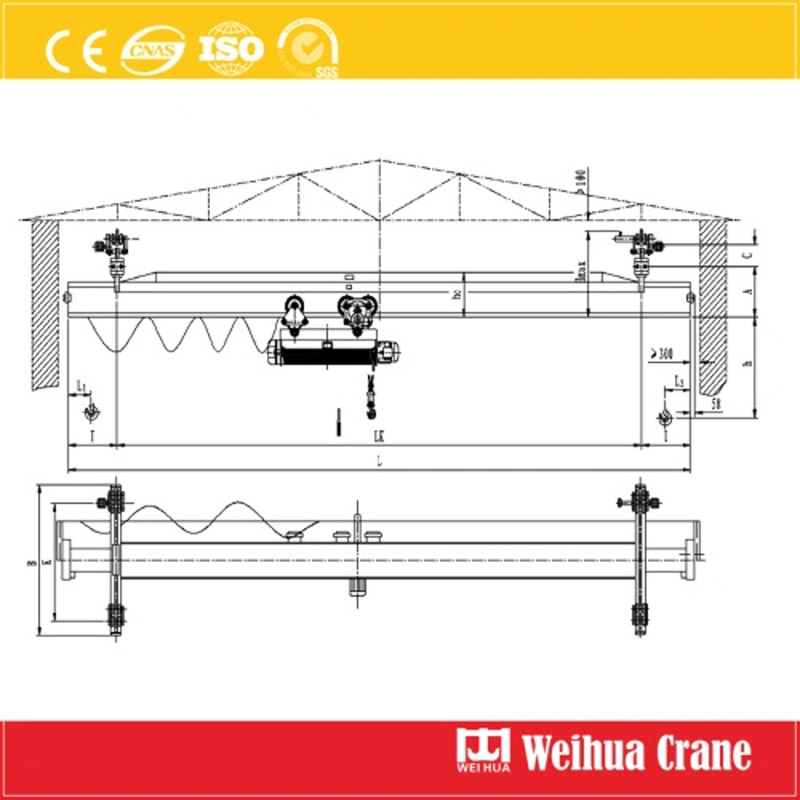

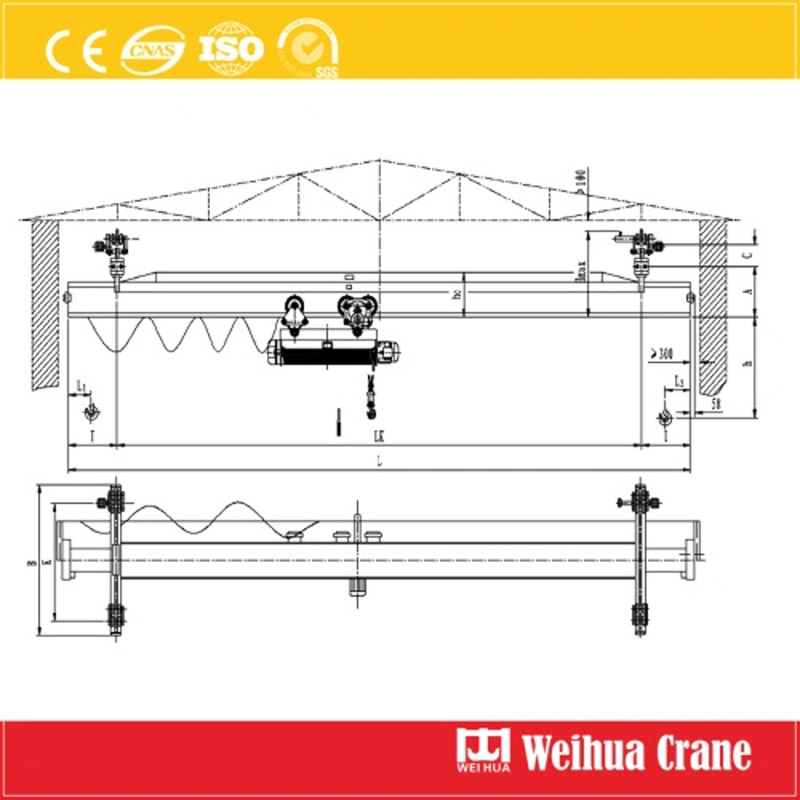

- 1. Visual and Physical Checks: Inspect the crane’s structure, including the bridge, wózek, wciągnik, and runway rails, for signs of damage (NP., spękanie, bent components, lub korozja). Ensure all fasteners, śruby, and pins are secure and not loose.

- 2. Load-Bearing Components: Examine wire ropes or chains for wear, wystrzępienie, załamania, or broken strands. Check hooks for deformation, spękanie, or excessive wear—never use a hook with a damaged latch. Verify that sheaves and drums are in good condition, with no grooves or damage that could compromise the rope.

- 3. Mechanical and Electrical Systems: Test the crane’s brakes (both hoist and travel brakes) to ensure they engage smoothly and hold loads securely. Check hydraulic or pneumatic systems for leaks. Inspect electrical connections, kable, and controls (NP., wisiorek, zdalny, or cabin controls) for damage, wystrzępienie, or malfunctions. Ensure emergency stop buttons are functional and easily accessible.

- 4. Urządzenia zabezpieczające: Confirm that all safety features are operational, including overload limit switches (prevents lifting loads beyond the crane’s capacity), systemy antykolizyjne (for multi-crane operations), wyłączniki krańcowe (prevent over-travel of the trolley or bridge), and warning devices (horns, lights, or alarms).

- 5. Work Area Assessment: Survey the lifting area to remove obstacles, clear pedestrians, and mark a safe zone (using barriers or caution tape if necessary). Check for overhead power lines—maintain the minimum safe distance as required by local regulations (zazwyczaj 10 feet or more for low-voltage lines). Ensure the load is balanced and properly secured with slings or shackles.

During Operation: Follow Best Practices for Safe Lifting

Once the pre-operation inspection is complete and the work area is secure, operators must adhere to these critical procedures during crane use:

- 1. Operator Competence: Only trained and certified operators should operate an overhead crane. Never allow unauthorized personnel to use the controls, and avoid distractions (NP., phone calls, conversations) while operating the crane.

- 2. Smooth Movements: Avoid sudden starts, zatrzymuje się, or changes in direction—these can cause the load to swing or shift, increasing the risk of accidents. Use gradual, controlled movements to lift, niżej, and position the load.

- 3. Load Handling: Never exceed the crane’s rated capacity. If the load weight is unknown, use a scale to weigh it first. Keep the load as low as possible during travel to minimize swing, and never drag or pull a stuck load—this can overload the crane or damage the rope. Avoid lifting loads over people, and never stand under a suspended load (even for a moment).

- 4. Communication: Establish clear communication with spotters or ground personnel using standard hand signals (NP., lift, niżej, stop, swing) or two-way radios. Ensure all parties understand the signals to avoid miscommunication. If visibility is poor (NP., due to dust, darkness, or obstacles), use a spotter to guide the operation.

- 5. Monitoring Equipment: Continuously monitor the crane’s performance during operation. If you notice unusual noises (NP., grinding, squealing), vibrations, or malfunctions (NP., brakes failing, controls unresponsive), stop the operation immediately, lower the load safely (możliwie), and shut off the power. Report the issue to a supervisor before resuming use.

- 6. Weather Considerations: Avoid operating the crane in extreme weather conditions (NP., high winds, ulewa, błyskawica) unless the crane is designed for such environments and proper safety measures are in place. High winds can cause loads to swing uncontrollably, while lightning poses an electrical hazard.

Post-Operation: Secure the Crane and Document Inspections

After completing the lifting task, operators must follow these steps to ensure the crane is safely secured and ready for the next use:

- 1. Park the Crane Properly: Move the crane to a designated parking area, away from work zones and pedestrian traffic. Lower the hoist hook to the lowest position (or as per company policy) and engage the brakes. Turn off the power to the crane and lock the control panel to prevent unauthorized use.

- 2. Secure the Load Area: Remove slings, kajdany, or other lifting accessories and store them in a designated location. Clean up the work area to remove debris or obstacles.

- 3. Document Inspections and Issues: Record the pre-operation inspection results, any issues encountered during operation, and maintenance needs in the crane’s logbook. This documentation helps track the crane’s condition over time, identify recurring problems, and ensure compliance with safety regulations.

- 4. Report Incidents: If an accident, near-miss, or equipment failure occurs during operation, report it to a supervisor immediately. Include details such as the date, time, location, nature of the incident, and any injuries or damage. Conduct a root-cause analysis to prevent similar incidents in the future.

Regularna konserwacja: Extend Equipment Life and Ensure Safety

In addition to pre and post-operation inspections, regular maintenance is critical to keeping overhead cranes safe and reliable. Employers should establish a preventive maintenance schedule based on the manufacturer’s recommendations and local regulations. Kluczowe zadania konserwacyjne obejmują:

- 1. Smarowanie: Regularly lubricate moving parts (NP., namiar, koła zębate, Paski) to reduce friction and wear.

- 2. Rope/Chain Maintenance: Replace worn, frayed, or damaged wire ropes or chains promptly. Inspect ropes for proper tension and alignment.

- 3. Brake and Control System Checks: Test brakes, silniki, and control systems periodically to ensure they function correctly. Adjust or replace components as needed.

- 4. Structural Inspections: Conduct annual or bi-annual structural inspections (by a qualified professional) to check for cracks, korozja, or fatigue in the crane’s frame, most, and runway.

- 5. Kalibrowanie: Calibrate overload limit switches and other safety devices regularly to ensure accuracy.

Wniosek: Safety Is a Collective Responsibility

Operating an overhead crane safely requires more than just following procedures—it demands a culture of safety where operators, przełożeni, and employers work together to prioritize risk mitigation. By conducting thorough pre-operation inspections, adhering to safe lifting practices, performing post-operation checks, and investing in regular maintenance, you can significantly reduce the risk of accidents and create a safer workplace for everyone.

Pamiętać, when it comes to overhead crane safety, there’s no room for shortcuts. Every step of the process—from inspection to operation to maintenance—plays a vital role in protecting lives and assets. By staying vigilant, following best practices, and continuously training operators, you can ensure that your overhead cranes operate safely and efficiently for years to come.

Najnowsze komentarze