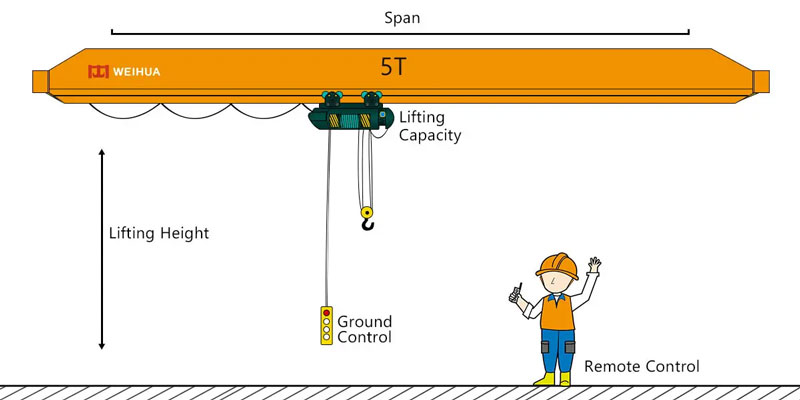

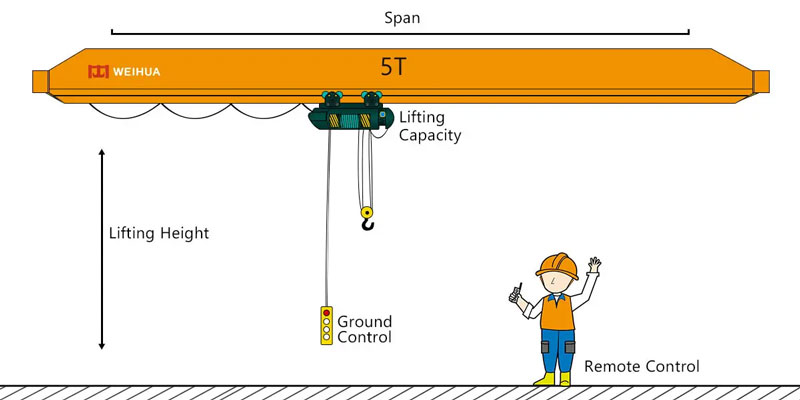

Overhead cranes are indispensable heavy-lifting equipment widely used in industrial settings, magazyny, place budowy, i zakłady produkcyjne. They play a crucial role in streamlining material handling processes, improving work efficiency, and ensuring the safe movement of heavy loads. To fully understand the operational mechanism of an suwnica, it is essential to familiarize oneself with its key parts and their respective functions. This article provides a comprehensive overview of the main components of an overhead crane and how they work together to deliver reliable lifting performance.

Jakie są części suwnicy?

1. Główna wiązka (Dźwigar mostu)

The main beam, also known as the bridge girder, is the primary load-bearing structure of the overhead crane. It spans the width of the workspace, connecting the two end trucks. Typically constructed from high-strength steel, the main beam is designed to withstand the weight of the lifted load, the crane’s own weight, and various dynamic forces during operation. Its robust structure ensures stability and rigidity, preventing excessive deflection when carrying heavy loads. The main beam also serves as the track for the trolley, allowing it to move horizontally along the length of the beam.

2. The End Beam Device (Wózki końcowe)

The end beam device are located at both ends of the main beam. Each end truck consists of wheels, axles, namiar, and a drive mechanism. The wheels ride along the crane runway rails installed on the building’s columns or elevated structures, enabling the entire crane to move longitudinally (along the length of the runway). The drive mechanism in the end trucks can be either electric or manual, depending on the crane’s design and application requirements. High-quality end trucks ensure smooth and precise movement of the crane, reducing friction and wear for long-term reliable operation.

3. Wózek

The trolley is a movable unit that travels along the main beam’s track. It carries the hoisting mechanism and is responsible for moving the load horizontally across the width of the crane’s span. Similar to the end trucks, the trolley is equipped with wheels, a drive system, and a braking system. The drive system powers the trolley’s movement, allowing it to position the load accurately above the desired location. The braking system ensures that the trolley stops securely when needed, preventing unintended movement during loading and unloading.

4. Hoisting Mechanism

The hoisting mechanism is the core component responsible for lifting and lowering the load.

It comprises an electric motor,

a gearbox, A

bęben linowy dźwigu, A

lina dźwigowa lub łańcuch,

and a hook block.

The electric motor provides the power,

which is transmitted to the gearbox to adjust the speed.

The gearbox then drives the drum to rotate,

winding or unwinding the wire rope or chain.

As the drum rotates, .

hook block attached to the end of the wire rope or chain moves up or down,

lifting or lowering the load.

The hoisting mechanism is equipped with safety devices such as limit switches to prevent overloading and overtravel,

ensuring safe operation.

5. System sterowania

The control system is the “brain” of the overhead crane, governing all its movements and operations. It includes a control panel (either pendant control, zdalne sterowanie, lub sterowanie kabiną), a frequency converter, and a PLC (Programowalny kontroler logiki). The operator uses the control panel to issue commands such as lifting, opuszczenie, ruch wózka, and crane travel. The frequency converter adjusts the speed of the motors, ensuring smooth acceleration and deceleration to avoid load sway. The PLC processes the input signals from the control panel and coordinates the operation of various components, enhancing the crane’s precision, efektywność, i bezpieczeństwo.

6. Urządzenia zabezpieczające

Safety is a top priority in overhead crane operation, and a range of safety devices are integrated into the crane to prevent accidents. Common safety devices include:

- 1. Overload Limiter: Detects the load weight and stops the hoisting operation if the load exceeds the crane’s rated capacity, protecting the crane and preventing structural damage.

- 2. Limit Switch: Includes upper and lower limit switches for the hoisting mechanism to prevent the hook block from overtraveling, and limit switches for the trolley and crane travel to restrict their movement within the designated range.

- 3. Emergency Stop Button: Allows the operator to immediately stop all crane operations in case of an emergency, ensuring the safety of personnel and equipment.

- 4. Anti-Collision Device: Prevents collisions between multiple cranes operating on the same runway by detecting the distance between cranes and triggering an alarm or stopping the crane if the distance is too close.

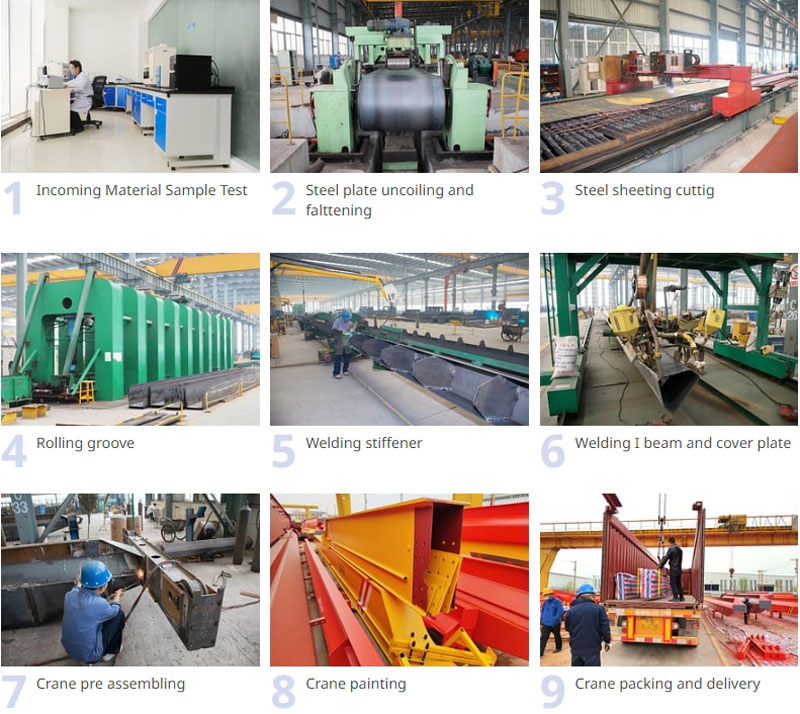

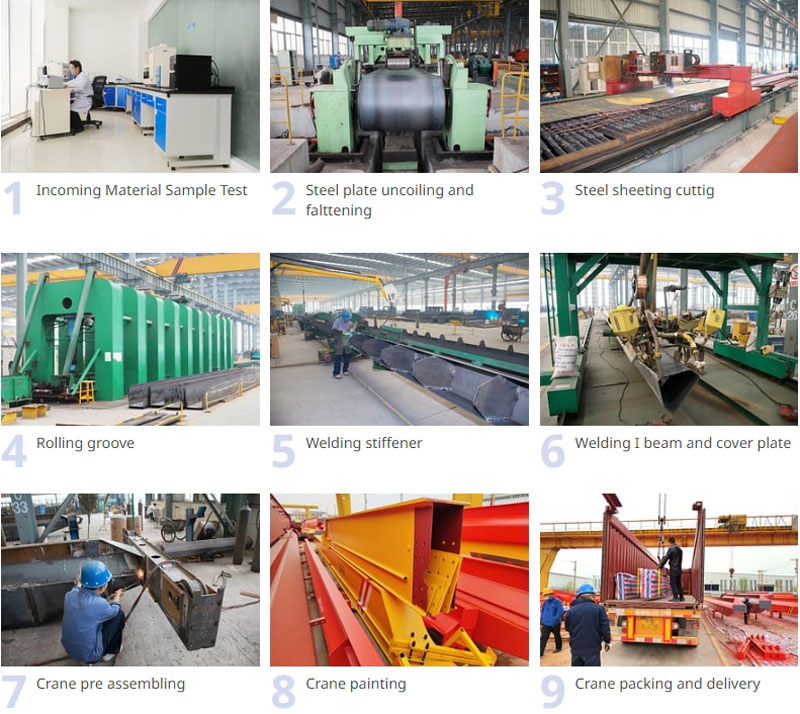

Overhead Crane Manufacturing Process

Overhead Crane Application Fields

Overhead cranes are widely used in various industries due to their versatile lifting capabilities. Some of the key application fields include:

- 1. Przemysł produkcyjny: Used for lifting and moving raw materials, semi-finished products, and finished products in factories producing machinery, automobiles, electronics, and appliances.

- 2. Magazynowanie i logistyka: Facilitates the loading, rozładunek, and stacking of goods in warehouses, distribution centers, i porty, improving storage and transportation efficiency.

- 3. Przemysł metalurgiczny: Handles heavy metal materials such as steel ingots, cewki, and castings in steel mills and foundries, operating in high-temperature and harsh environments.

- 4. Przemysł budowlany: Used on construction sites for lifting construction materials, sprzęt, and components, assisting in the construction of buildings, bridges, and other structures.

Advantages of Our Overhead Cranes

Our overhead cranes are designed and manufactured with a focus on quality, performance, i bezpieczeństwo. Key advantages include:

- 1. High-quality materials and precision manufacturing ensure long service life and reliable operation even in demanding industrial environments.

- 2. Advanced control systems and safety devices provide precise load positioning and comprehensive accident prevention, minimizing operational risks.

- 3. Customizable designs to meet the specific requirements of different industries, including various load capacities, span lengths, and lifting heights.

- 4. Efficient energy consumption and low maintenance costs, reducing overall operational expenses for our customers.

In conclusion, understanding the parts and functions of an overhead crane is vital for selecting the right equipment, ensuring safe operation, and maximizing its performance. Our overhead cranes combine advanced technology, superior quality, and comprehensive safety features to provide efficient and reliable material handling solutions for diverse industrial applications. If you have any inquiries or need a customized overhead crane solution, prosimy o kontakt z nami.

Udostępnij w formacie PDF: Pobierać

Najnowsze komentarze