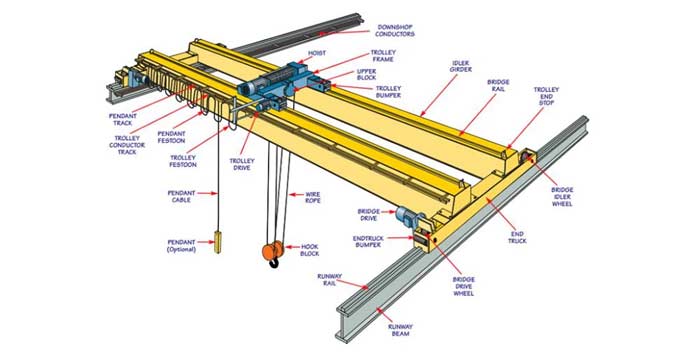

Overhead cranes are the workhorses of manufacturing plants, magazyny, place budowy, i obiektów przemysłowych, enabling the safe and efficient lifting of heavy loads. Behind their robust performance lies a set of carefully engineered components that work in harmony. Understanding these overhead crane components is essential for operators, maintenance teams, and anyone involved in material handling operations. Let’s dive into the core structures that make overhead cranes reliable and functional.

Main Girder

The main girder is the primary horizontal beam of the suwnica, obejmujący szerokość obszaru roboczego. It serves as the backbone of the crane, supporting the entire weight of the load, wózek, and lifting mechanism.

Ciężarówki końcowe

End trucks are mounted at both ends of the main girder, acting as the “feet” of the overhead crane. They connect the girder to the crane runway and enable horizontal movement along the track.

wózek

The trolley is a movable unit that travels along the length of the main girder, allowing the lifting mechanism to reach different positions within the crane’s span.

The drum is a cylindrical component that stores the lifting rope or chain, playing a critical role in raising and lowering the load.

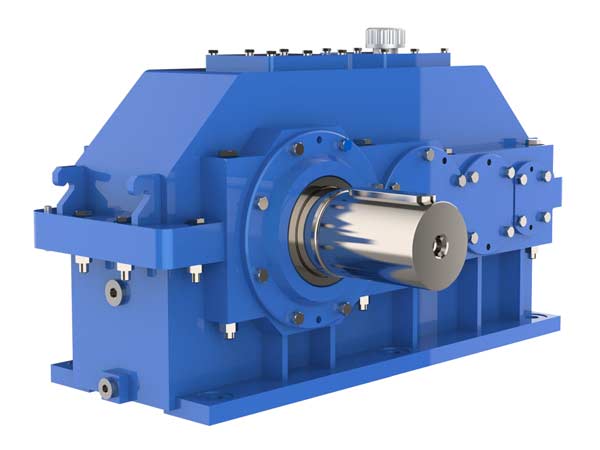

skrzynia biegów

The gearbox is a power transmission component that adjusts the speed and torque from the motor to match the crane’s operational needs.

Hoisting Mechanism

The hoisting mechanism is the heart of the overhead crane, responsible for vertically lifting and lowering the load. It integrates several key components into a cohesive system.

Odbierak prądu dźwigowy

The electrical system is the control center of the overhead crane, powering all mechanisms and ensuring safe operation.

Ogranicznik wysokości podnoszenia

Safety systems are non-negotiable components that protect operators, sprzęt, and loads from accidents.

Each overhead crane component plays a vital role in ensuring the equipment’s performance, bezpieczeństwo, and longevity. From the main girder’s structural support to the safety system’s fail-safes, every part must be properly maintained and inspected regularly. A well-maintained crane not only minimizes downtime but also protects workers and valuable assets.

Whether you’re investing in a new overhead crane or maintaining an existing one, understanding these key components helps you make informed decisions about operation, konserwacja, and upgrades. By prioritizing component integrity, you can maximize the crane’s efficiency and extend its service life.

If you need a detailed component maintenance checklist or want to learn more about selecting the right overhead crane for your application, feel free to reach out. Our team of experts is here to help you optimize your material handling operations!

Udostępnij w formacie PDF: Elementy suwnicy

Cenimy twoją opinię! Wypełnij poniższy formularz, abyśmy mogli dostosować nasze usługi do twoich konkretnych potrzeb.

Kliknij przycisk, aby uzyskać informacje o produkcie i cytaty na WhatsApp.

Zdobądź wycenę

Najnowsze komentarze