Wymiary haczyka dźwigu mostowego

2025-08-05

When you picture a bridge crane, the hook is likely the most recognizable component – that sturdy, curved piece of metal doing the heavy lifting. But did you know that the dimensions of that hook are absolutely critical to safe, wydajny, and reliable operation? Choosing the wrong size hook isn’t just inconvenient; it’s a significant safety hazard.

Understanding the key dimensions involved helps you select the right hook for the job, ensure compatibility with your lifting gear, and maintain compliance with safety standards (like ASME B30.10 for hooks).

Key Hook Dimensions Explained

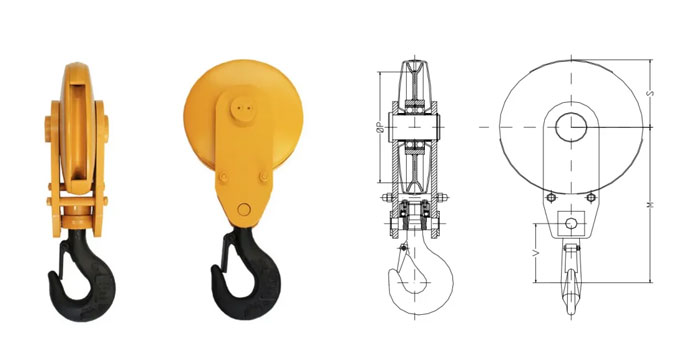

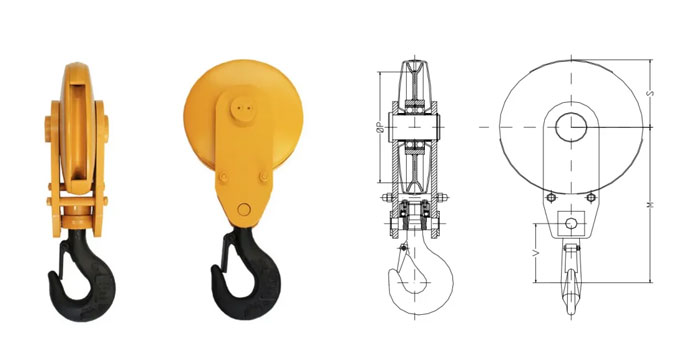

-

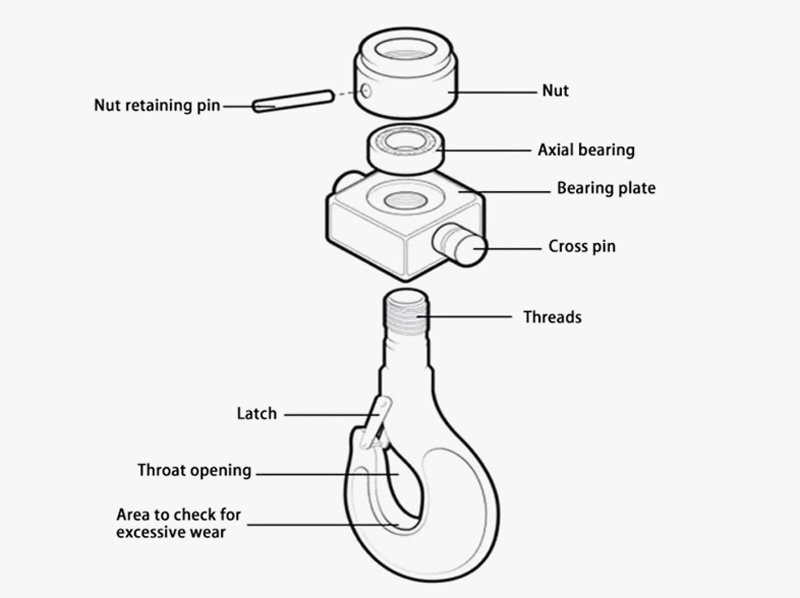

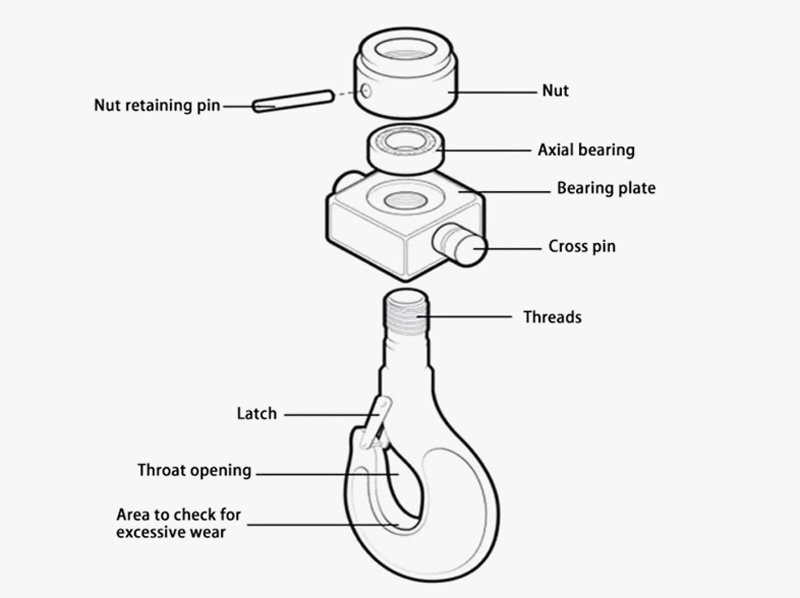

1. Haczykowe otwarcie gardła (A): This is the horizontal distance measured at the widest point inside the hook’s curve. It’s arguably the most crucial dimension for usability.

- Why it matters: The throat opening must be large enough to comfortably accommodate the slings, kajdany, or other rigging hardware you’ll be using. A throat too small forces rigging to pinch or sit precariously, increasing the risk of slippage or damage. Ogólnie, the throat opening should be at least 15-20% larger than the widest component of your rigging.

-

2. Hook Throat Depth (B): This is the vertical distance from the bearing point at the bottom of the hook shank (where the load naturally sits) to the inside top of the hook tip. Think of it as the “usable depth.”

- Why it matters: Adequate depth ensures the load or rigging sits securely within the hook’s curve (“in the saddle”), preventing it from riding up towards the tip where it could slip off, especially during dynamic movements. Deeper throats generally provide more secure seating.

-

3. Shank Diameter (C): This is the diameter of the hook’s straight upper section, just below the swivel or eye (jeśli ma to zastosowanie).

- Why it matters: The shank diameter is directly related to the hook’s rated capacity. It’s a primary factor in the hook’s strength calculation. Larger diameters correspond to higher load ratings. Never attempt to use a hook where the shank diameter looks undersized for the load – it’s a major red flag.

-

4. Hook Tip Clearance (D): The distance between the very tip of the hook and the shank. Sometimes referred to as the “gap” or “point clearance.”

- Why it matters: While less critical than throat opening for rigging fit, sufficient clearance prevents the tip from binding against the shank when the hook is under load or at an angle. It also allows space for safety latches to function correctly.

-

5. Eye or Swivel Opening (E): If the hook has a top eye or is part of a swivel assembly, the internal diameter of that opening is vital.

- Why it matters: This dimension must match the diameter of the crane’s lower hoist block pin (clevis pin). A mismatch prevents proper installation or creates dangerous point loading. This is a non-negotiable compatibility requirement.

Why Getting Dimensions Right is Non-Negotiable

- 1. Bezpieczeństwo: The paramount concern. An undersized hook, a hook with insufficient throat opening causing pinched slings, or a hook not securely attached due to pin mismatch can lead to catastrophic failure, dropped loads, injuries, and fatalities.

- 2. Load Security: Correct dimensions ensure rigging sits properly within the hook, minimizing the risk of slippage during lifting, wahadłowy, or lowering.

- 3. Efektywność: Using the right-sized hook makes rigging easier, szybciej, and safer. No struggling to fit slings into a too-small throat.

- 4. Equipment Longevity: Properly sized hooks experience less stress and wear. Using a hook that’s too small or forcing rigging into it accelerates fatigue and damage.

- 5. Zgodność: Adherence to standards like ASME B30.10 requires using hooks with dimensions appropriate for their rated capacity and application.

Choosing the Right Hook: It’s Not Just About Tonnage!

While the crane’s rated capacity determines the minimum load rating the hook must have (NP., a 10-ton crane needs a hook rated for at least 10 mnóstwo), the specific dimensions are equally important:

- 1. Know Your Rigging: What are the dimensions (szerokość, thickness) of your most commonly used slings, kajdany, or other attachments? Your hook’s throat opening must accommodate them.

- 2. Know Your Crane’s Lower Block: What is the diameter of the clevis pin on the hoist block? Your hook’s eye/swivel opening must match this exactly.

- 3. Consider the Application: Are you lifting wide, bulky loads? A deeper throat (B) might be beneficial. Lifting multiple small items with specialized rigging? Otwarcie gardła (A) is key.

- 4. Consult the Manufacturer’s Specifications: Always refer to the OEM (Original Equipment Manufacturer) specifications for the crane and the hook itself. These provide the definitive dimensions and load ratings. Never rely solely on visual estimation.

- 5. Inspect for Wear: Regularly inspect hooks for wear, especially in the throat and shank areas. Wear reduces the effective dimensions and weakens the hook. Measure critical dimensions periodically and compare them to the OEM specs. Replace hooks that show excessive dimensional reduction or deformation.

Bridge crane hook dimensions are precise engineering parameters, not arbitrary measurements. Ignoring them compromises safety, efektywność, and the integrity of your lifting operations. Always prioritize selecting a hook with the correct load rating AND the appropriate dimensional fit for your rigging and crane connection. W razie wątpliwości, consult the manufacturer’s specs or a qualified lifting equipment specialist. Don’t let a few millimeters be the weak link in your lift!

Najnowsze komentarze