Op rails gemonteerde portaalkraan (RMG): Hoge capaciteit, aanpasbare hijsoplossingen voor havens, containerwerven & industriële faciliteiten. Verhoog de efficiëntie met stabiliteit, veiligheid & weinig onderhoud.

op rails gemonteerde portaalkraan voor windenergie

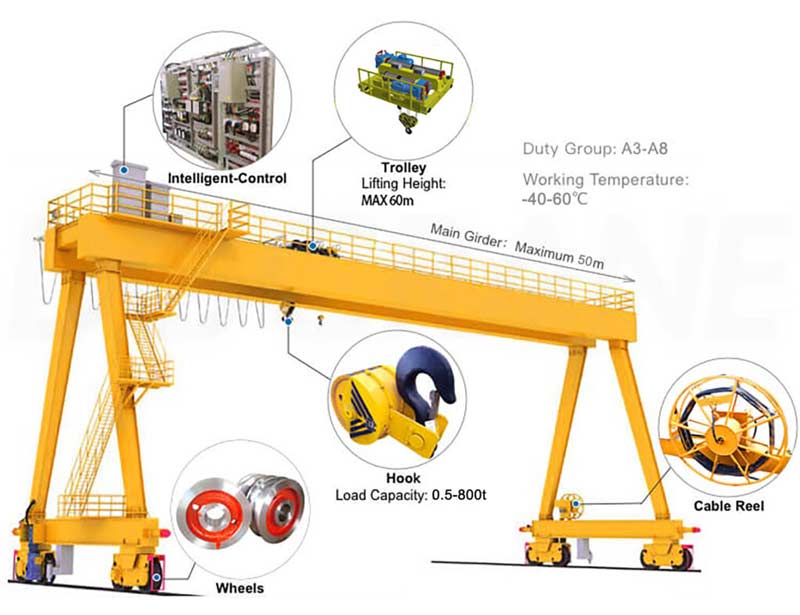

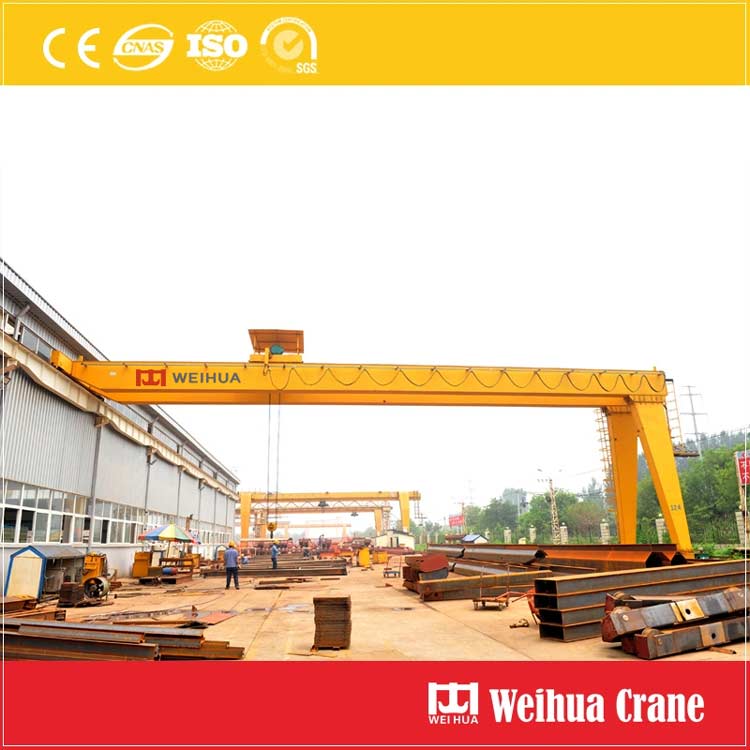

Een op rails gemonteerde portaalkraan (RMG-kraan) is een robuust, Hefsysteem met hoge capaciteit, ontworpen voor gebruik op vaste spoorrails, waardoor het ideaal is voor nauwkeurig, repetitieve materiaalbehandeling in grootschalige faciliteiten. De RMG-kranen zijn ontworpen om zware lasten te verwerken – van containers en bulkgoederen tot industriële apparatuur – en leveren ongeëvenaarde efficiëntie in havens, containerwerven, intermodale terminals, en industriële opslagfaciliteiten.

Of u het stapelen van containers wilt stroomlijnen, de vrachtomzet versnellen, of optimaliseer de tuinruimte, onze op rails gemonteerde portaalkranen zijn gebouwd om te voldoen aan de eisen van operaties met hoge doorvoer.

op rails gemonteerde portaalkraan voor containers

Onze RMG-kranen zijn ontworpen met geavanceerde technologie en duurzame materialen om betrouwbaarheid te garanderen, veiligheid, en prestaties op lange termijn. Dit is wat hen onderscheidt:

|

Parameter

|

Bereik (Aanpasbaar)

|

|

Maximaal hefvermogen

|

20T – 150T

|

|

Overspanningslengte

|

10m – 40 m

|

|

Hefthoogte

|

6m – 25 m

|

|

Reissnelheid

|

0-40 m/mijn (verstelbaar)

|

|

Hijssnelheid

|

0-15 m/mijn (verstelbaar)

|

|

Stroomvoorziening

|

380V/50 Hz (of op maat)

|

|

Besturingssysteem

|

Afstandsbediening + bediening cabine

|

Onze RMG-kranen zijn veelzijdig genoeg om meerdere industrieën te bedienen, inbegrepen:

portaal met rubberen banden (RTG) kranen

Inzicht in de verschillen tussen op rails gemonteerde portaalkranen (RMG) en portaalkranen met rubberbanden (RTG) is cruciaal voor het selecteren van de juiste material handling-oplossing. Hieronder vindt u een gedetailleerde vergelijking van hun belangrijkste voordelen:

|

Vergelijkingsdimensie

|

Op rails gemonteerde portaalkraan (RMG)

|

|

|

Mobiliteit & Flexibiliteit

|

Werkt op vaste rails voor stabiliteit, voorspelbare beweging; ideaal voor speciale werkzones met consistente workflows.

|

Het op banden gebaseerde ontwerp maakt onbeperkte beweging over yards mogelijk; geschikt voor dynamische lay-outs die frequente herpositionering vereisen. 5G-compatibele afstandsbedieningsmodellen vergroten de operationele flexibiliteit verder.

|

|

Laadvermogen & Stabiliteit

|

Superieure stabiliteit vanaf de railfundering; ondersteunt belastingen van 20T–150T (aanpasbaar voor ultrazware lading) met nauwkeurige positionering.

|

Kan doorgaans ladingen van 40T–60T verwerken; bandophanging kan de stabiliteit verminderen bij extreme gewichten of hoge stapelhoogtes.

|

|

Gebruik van de ruimte

|

Dichte stapelmogelijkheden (tot 6+ containers hoog) maximaliseert de tuinruimte; De spoorinrichting optimaliseert de verkeersstroom voor operaties met hoge doorvoer.

|

Vereist grotere draairadii en afstand tussen units; beperkt de stapeldichtheid in vergelijking met RMG-systemen.

|

|

Energie-efficiëntie & Onderhoud

|

Regeneratief remmen en motoren met laag vermogen verlagen de energiekosten; minimale bewegende delen in railsystemen verminderen de onderhoudsfrequentie.

|

Elektrische RTG-modellen verminderen het dieselverbruik, maar het vervangen van banden en het onderhoud van de ophanging brengt kosten op de lange termijn met zich mee.

|

|

Toepassingsgeschiktheid

|

Het beste voor grootschalige containerterminals, intermodale werven, en industriële faciliteiten met vaste, workflows met grote volumes.

|

Bij voorkeur voor middelgrote tuinen, tijdelijke projecten, of faciliteiten die periodieke aanpassingen van de indeling nodig hebben.

|

Voor operaties waarbij prioriteit wordt gegeven aan stabiliteit, behandeling van zware lasten, en ruimte-efficiëntie, RMG-kranen leveren waarde op de lange termijn. RTG-systemen blinken uit in scenario's die flexibiliteit vereisen, positionering op aanvraag.

Q1: Hoe vaak heeft een op rails gemonteerde portaalkraan onderhoud nodig??

A: Routinematig onderhoud (smering, inspectie) wordt elke aanbevolen 3 maanden, met jaarlijks groot onderhoud: ons team kan deze controles voor u plannen en uitvoeren.

Q2: Kunnen RMG-kranen in nauwe ruimtes opereren??

A: Ja, wij bieden compacte modellen met kleinere overspanningen, zodat ze op krappe terreinen passen en tegelijkertijd hoge prestaties behouden.

Q3: Voldoen uw kranen aan de veiligheidsvoorschriften??

A: Absoluut. Al onze RMG-kranen voldoen aan OSHA, EU, en internationale veiligheidsnormen, met ingebouwde functies om ongelukken te voorkomen.

Klaar om de efficiëntie in uw instelling te verhogen? Neem vandaag nog contact met ons op voor een gratis adviesgesprek en offerte. Onze experts helpen u bij het selecteren van de perfecte op rails gemonteerde portaalkraan voor uw behoeften.

Deel met PDF: Downloaden

Wij waarderen uw feedback! Vul het onderstaande formulier in, zodat we onze services kunnen aanpassen aan uw specifieke behoeften.

Polyurethaanbuffers worden veel toegepast in bovenloopkranen, portaalkranen, takels, en anders......

Ontdek meer →

The Rope Guide System is a state-of-the-art anti-sway and guidance solution designed for……

Ontdek meer →

De explosieveilige enkelligger-bovenloopkraan is een gespecialiseerd hijsmiddel dat me……

Ontdek meer →

Klik op de knop om productinformatie en offertes op WhatsApp te krijgen.

Krijg citaat

Laatste opmerkingen