Een enkele ligger, elektrisch boven het hoofd reizend (EOT) Kraan is een fundamenteel en zeer veelzijdig stuk materiaaltransportapparatuur. Het is ontworpen voor het efficiënt horizontaal en verticaal verplaatsen van zware lasten binnen een gedefinieerde werkruimte, typisch een fabriek, magazijn, of werkplaats.

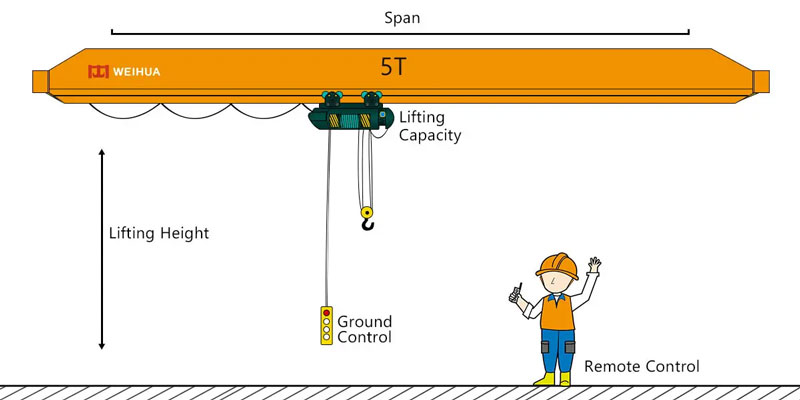

De kernconstructie van de eot-kraan met enkele ligger bestaat uit een brug die aan beide uiteinden wordt ondersteund door eindwagens die langs de baanbalk lopen. Een kraan- en wagenmechanisme beweegt langs de onderflens van de hoofdbalk, waardoor hijs- en zijwaartse beweging mogelijk is. Enkelligger EOT-kranen staan bekend om hun kosteneffectiviteit, eenvoud en betrouwbaarheid, waardoor ze de ideale oplossing zijn voor een verscheidenheid aan lichte tot middelzware toepassingen. De kraan werkt op verhoogde baanrails, waardoor waardevolle vloerruimte eronder vrijkomt.

1. Kosteneffectieve oplossing

Door de eenvoudigere uitvoering met slechts één hoofdligger, dit kraantype vereist minder materiaal en is economischer te vervaardigen en te installeren vergeleken met een dubbelliggerkraan, biedt een uitstekende prijs-kwaliteitverhouding.

2. Compact en ruimtebesparend ontwerp

De enkelliggerconstructie heeft een lagere stahoogte, waardoor het perfect is voor faciliteiten met hoogtebeperkingen. Hierdoor wordt de bruikbare hefhoogte onder de haak gemaximaliseerd.

3. Robuuste en betrouwbare prestaties

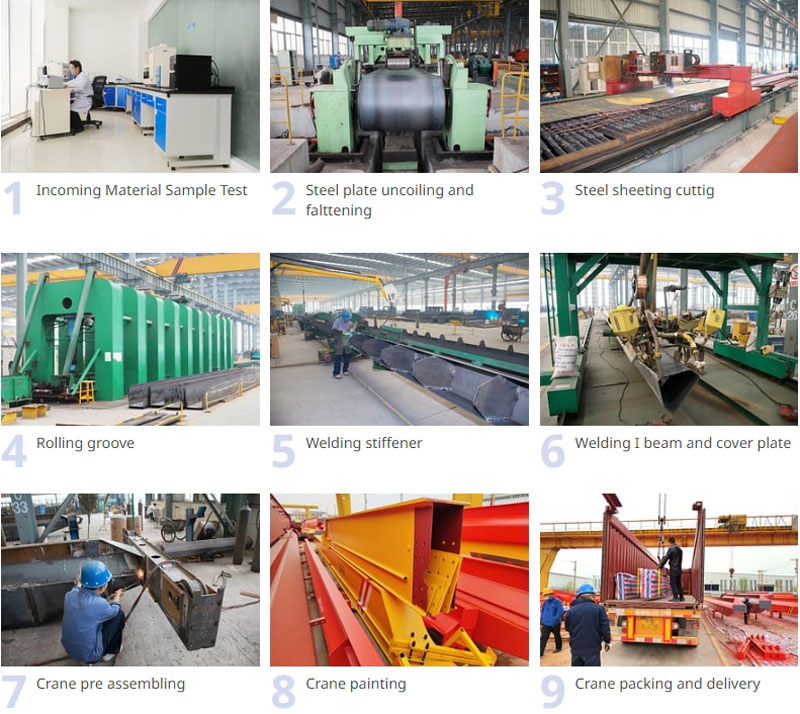

Gebouwd uit hoogwaardig staal, de hoofdligger is ontworpen om intensief gebruik te weerstaan met minimale doorbuiging. De gehele structuur zorgt voor een stabiele en betrouwbare werking gedurende een lange levensduur.

4. Eenvoudige installatie en weinig onderhoud

Het eenvoudige ontwerp vertaalt zich in een eenvoudigere en snellere installatie. Met minder componenten dan complexere kranen, onderhoud is eenvoudig, en de operationele downtime wordt verminderd.

5. Soepele en nauwkeurige bediening

Uitgerust met hoogwaardige elektrische takels en aangedreven eindwagens, deze kranen zorgen voor een soepele verplaatsing, nauwkeurige positionering van de last, en stille werking, het verbeteren van de veiligheid en efficiëntie op de werkplek.

6. Verbeterde veiligheidsfuncties

De standaard veiligheidsuitrusting omvat overbelastingseindschakelaars, eindschakelaars voor zowel brug- als takelbewegingen, noodstopknoppen, en thermische beveiliging voor motoren, zorgen voor een veilige werkomgeving.

7. Aanpassingsopties

Terwijl het een standaardproduct is, deze kranen kunnen op maat gemaakt worden met diverse hijsvermogens, overspant, hefsnelheden, en besturingsmogelijkheden (hangende bediening of radiografische afstandsbediening) om aan specifieke toepassingsbehoeften te voldoen.

De volgende tabel geeft een overzicht van de standaardspecificaties. Aangepaste configuraties zijn beschikbaar.

| Parameter | Specificatiebereik | Aantekeningen |

| Hefcapaciteit | 1 Ton aan 20 Ton | Standaard capaciteiten; aangepaste ontwerpen beschikbaar. |

| Span | 5 Meter tot 25 Meters | De afstand tussen baanrails. |

| Hefthoogte | Tot aan 30 Meters | Aanpasbaar volgens vereiste. |

| Werk plicht | A3 / Klas 2 (Licht tot matig) | Geschikt voor intermitterend gebruik. |

| Controlemodus | Hangerbediening / Radiografische afstandsbediening | Bedrade hanger is standaard; draadloze afstandsbediening is optioneel. |

| Stroomvoorziening | 3 Fase, 380V / 400V / 415V, 50Hz | Kan worden aangepast aan de lokale energienormen. |

| Omgevingstemperatuur | -20°C tot +40°C | Geschikt voor de meeste industriële omgevingen. |

| Reissnelheid | 20 m/mijn (ca.) | Snelheid van de kraan langs de baan. |

| Hijssnelheid | 8 m/mijn (ca.) | Snelheid van het heffen/dalen van de last. |

Enkelligger EOT-kranen zijn werkpaarden in tal van industrieën:

Q1: Wat is het belangrijkste verschil tussen een enkelligger en een dubbelligger EOT-kraan?

A: Een enkelliggerkraan heeft één hoofdbalk die de takel ondersteunt, die op de onderflens loopt. Een dubbele ligger heeft twee hoofdliggers, waarbij de takel ertussen loopt op een bovenop gemonteerde trolley. Voor zwaardere capaciteiten worden dubbelliggerkranen ingezet (>20T), vereisen een grotere hoofdruimte, en zijn duurder maar bieden een grotere haakhoogte.

Q2: Kan de kraan buiten gebruikt worden??

A: Ja, maar het vereist specifieke aanpassingen. Een buitenkraan wordt doorgaans geleverd met een beschermingsgraad IP54 of hoger, anti-corrosie verf, en andere functies zoals windhaken om hem vast te zetten wanneer hij niet in gebruik is.

Q3: Hoe wordt de kraan aangedreven?

A: De meest gebruikelijke methode is via een festoensysteem of stroomrails die langs de landingsbaan lopen, het leveren van continue stroom aan de kraan. Als alternatief, kabelhaspels kunnen worden gebruikt.

Q4: Welk onderhoud is er nodig?

A: Regelmatig onderhoud omvat visuele inspecties, controleren op slijtage van wielen en remmen, ervoor te zorgen dat elektrische componenten functioneel zijn, en het smeren van bewegende delen. Een jaarlijkse professionele inspectie wordt ten zeerste aanbevolen.

Vraag 5: Kan ik de capaciteit van mijn bestaande enkelliggerkraan later vergroten??

A: Nee. Kranen zijn ontworpen en gebouwd voor een bepaalde maximale capaciteit. Pogingen om deze beoordeling te overschrijden zijn uiterst gevaarlijk. De hele structuur, inclusief de ligger, eindrijtuigen, en hijsen, is geschikt voor de oorspronkelijke capaciteit.

Vraag 6: Hoe kies ik de juiste capaciteit en overspanning?

A: U moet het maximale gewicht kennen van de lasten die u gaat hijsen en de exacte afstand tussen de steunkolommen van de start- en landingsbaan in uw faciliteit. Het is altijd raadzaam om ons engineeringteam te raadplegen om een veilig en optimaal ontwerp te garanderen.

Wij waarderen uw feedback! Vul het onderstaande formulier in, zodat we onze services kunnen aanpassen aan uw specifieke behoeften.

Ons 80 tons overhead crane is a bridge-type lifting device installed on the upper part ……

Ontdek meer →

10 Ton dubbele ligger boven het hoofd (EOT) Crane Product Overview The 10 Tons Double Girder ……

Ontdek meer →

De 200 tons overhead crane is a heavy-duty lifting equipment designed to meet the dema……

Ontdek meer →

Klik op de knop om productinformatie en offertes op WhatsApp te krijgen.

Krijg citaat

Laatste opmerkingen