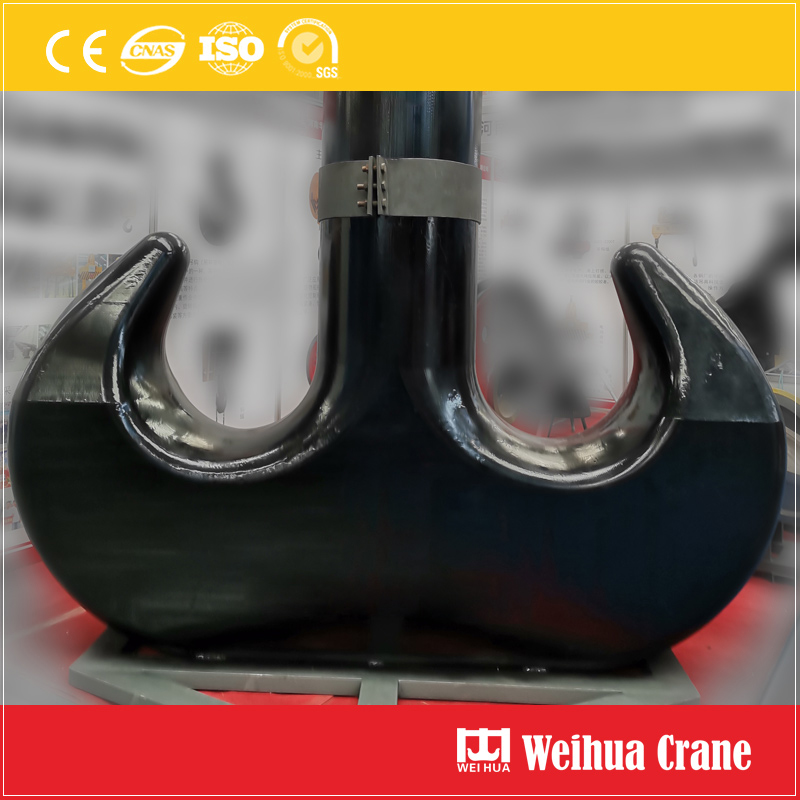

In the world of overhead cranes and hoists, maintenance is not just about preventing downtime—it’s about ensuring absolute safety. The crane hook is the final critical link between your load and your equipment. A failure here can be catastrophic. Often overlooked, a proper crane hook lubrication procedure is paramount for smooth operation, veiligheid, and the longevity of your equipment.

This comprehensive guide will walk you through the why, what, and how of correctly lubricating your crane hook’s swivel bearing.

The hook assembly swivels to prevent load lines from twisting and becoming damaged. This swivel action is made possible by a thrust bearing or a set of washers. Without proper lubrication:

Before beginning any crane hook maintenance, adhere to these critical safety protocols:

Follow these steps to ensure a thorough and effective lubrication service.

Stap 1: Inspection and Cleaning

Thoroughly clean the exterior of the hook assembly. Locate the grease fitting (zerk fitting) and the grease relief port (usually a small hole or a gap in the housing opposite the zerk). Use your pick tool and brush to carefully remove all old, hardened grease, vuil, and metal particles from the relief port. This step is crucial—if the relief port is blocked, you cannot inject new grease.

Stap 2: Purge Old Grease

Attach your grease gun to the zerk fitting. Slowly pump new grease into the fitting. You will see old, discolored grease begin to purge from the relief port. Continue pumping until the grease coming out of the relief port appears clean and fresh. This ensures all old contaminants are flushed from the bearing cavity.

Stap 3: Rotate the Hook

While purging the old grease, have a colleague (or use your free hand) to slowly rotate the hook back and forth. This movement helps the new grease circulate completely throughout the entire bearing assembly, ensuring full coverage.

Stap 4: Wipe Clean and Final Check

Once clean grease is exiting the port, stop pumping. Over-greasing can damage seals. Wipe away all excess grease from the hook, zerk fitting, and relief port. Manually rotate the hook to confirm it moves smoothly and freely without any binding or gritting sensation.

Stap 5: Document the Maintenance

Record the date, hours of operation, and the type of grease used in your maintenance log. This helps establish a predictive maintenance schedule and is vital for compliance and safety audits.

A proper crane hook lubrication procedure is a simple yet vital task that directly impacts operational safety and equipment reliability. By integrating this process into your regular preventive maintenance schedule—typically every 3 naar 6 maanden, or as specified by the OEM—you protect your workforce, uw lading, and your capital investment. Never underestimate the power of a well-greased hook.

Vrijwaring: Always prioritize the instructions and maintenance schedules provided in the original equipment manufacturer (OEM) manual for your specific crane and hook model.

Wij waarderen uw feedback! Vul het onderstaande formulier in, zodat we onze services kunnen aanpassen aan uw specifieke behoeften.

Klik op de knop om productinformatie en offertes op WhatsApp te krijgen.

Krijg citaat

Laatste opmerkingen