As the core field of crane application, the metallurgical industry has demands that run through key processes such as metal smelting, rollend, en gieten. It puts forward stringent requirements for equipment in terms of stability, veiligheid, and high degree of customization. It is the core driving force for the technological upgrading of lifting equipment and the development of intelligent manufacturing.

As a leader in the industry, Weihua has always been guided by the needs of the metallurgical market, constantly promoted technological innovation and product iteration, and created a full range of metallurgical lifting solutions covering the entire process, including casting cranes, forging cranes, and quenching cranes. The diversified and specialized product system, including machines, charging cranes, slab clamping cranes, electromagnetic beam hanging cranes, and metallurgical gantry cranes, can fully meet the operating environment of complex metallurgical processes and harsh working conditions, and help customers improve production efficiency and intelligence levels.

500t casting crane for a steel project in Weihua

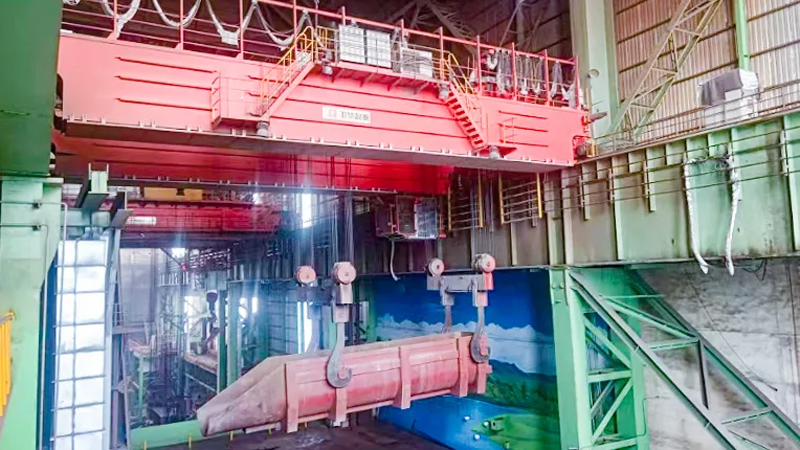

320t casting crane for a steel project in Weihua

Foundry cranes are key equipment for the metallurgical and foundry industries to cope with harsh environments of high temperatures, zware lasten, and high dust. They are centered on high safety, high reliability, and special structural adaptability.

This series of cranes adopts a “mechanical + electrical” dual redundancy design and is equipped with dual-domain vector decoupling drives for hoisting and displacement to achieve low-carbon and smooth operation. Through structural strength topology reconstruction design and “three-layer blocking + structural cooling + material slow decay” collaborative heat insulation, it can adapt to harsh working conditions. It is supplemented by multi-dimensional safety monitoring to comprehensively protect human and machine safety and ensure durability and reliability in high-frequency operations.

Weihua YD250t forging crane

Forging cranes are special lifting equipment designed for high temperatures, zware lasten, frequent lifting and complex operating environments. They mainly serve forging workshops and related high-temperature workplaces. They are irreplaceable in the field of metal processing and are especially suitable for the forging, handling, turning and positioning process of heated forgings.

Its advantages are high temperature resistance and structural stability. The bridge structure is optimized and equipped with heat insulation protection, which is suitable for high temperature and heavy load conditions. It adopts integrated PLC or industrial control system to improve the level of intelligent operation. It has strict multiple safety protections. It adopts a modular structure to facilitate quick installation and maintenance. It supports personalized customization to meet the needs of different workshops and processes. It has become an indispensable core equipment in forging production with high performance, high adaptability and high reliability.

Quenching crane for a project in Weihua

The quenching crane is a special crane designed for high-temperature quenching process environments. It is designed for high-temperature scenarios such as heat treatment and forging. It adopts corrosion-resistant coating technology and heat-insulating structure, and is equipped with a dust-proof and moisture-proof electrical system. It is suitable for high-humidity working conditions such as salt baths and water quenching.

Through high-strength structural design, frequency conversion speed regulation, energy saving and multiple safety protections (overload/limit/brake), the smooth and safe operation of heavy loads is ensured; modular customization meets the process needs of different workshops and is the core equipment of high-temperature quenching production.

Weihua lower rotating beam crane

The equipment adopts a double lifting point single motor driven double drum structure. The single winding design of the steel wire does not require multiple turns. The rotating electromagnetic hanging beam can achieve 0° to -240° rotation, which can flexibly meet the needs of turning and cross-stacking, and is suitable for diverse operating scenarios.

In terms of safety protection, the innovative triple protection mechanism of “double rising limit + drum end rotation limit + trolley frame heavy hammer anti-top protection” is specially developed for the space-limited rotation and placement scenarios of long strips of magnetic metal such as steel plates and steel sections. It is widely used in steel smelting, scheepsbouw, port logistics and other industries to facilitate material transfer and storage upgrades under complex working conditions.

Weihua 110t ultra-high temperature slab handling crane

The advantage of this product is its strong applicability, supporting the lifting, installatie, and maintenance of multiple materials such as steel coils and billets. The parameters can be customized and is suitable for complex environments such as high temperature, high dust, and heavy loads;

The structure adopts box beam topology optimization + innovative design of integrated main end beam, hoogwaardig gelegeerd staal + advanced welding to improve stiffness and strength reliability; with “clamping instead of bundling” as the core, it has the characteristics of high automation and quick-change clamps. It is widely used in the non-damage handling of finished metal plates/sections in steel, scheepsbouw, port storage, enz. It is an important equipment for metal materials and steel rolling production lines.

Weihua charging crane

As a special equipment dedicated to the steel mill’s feeding span, the charging crane is deeply adapted to the stringent requirements of the steelmaking process and empowers efficient production with its three core advantages of “resistance, stability and intelligence”.

Its design is in line with the harsh working conditions of the steelmaking process. Key components are made of high-temperature resistant materials. High-strength steel and advanced welding processes are used to create a rigid bridge. It is equipped with a PLC + touch screen intelligent system and an MES system. It integrates core properties such as high temperature resistance, dust resistance, high reliability, high stability, and precise speed regulation. It can withstand high temperatures at the furnace mouth and high dust environments of thousands of degrees, achieve precise feeding, intelligent scheduling, stable operation and low failure rate.

As a key piece of equipment in the steel smelting process, it significantly improves production efficiency and builds a solid line of defense for operational safety with its stable and efficient feeding capacity and multiple safety guarantees.

500 tons heavy structural parts annealing furnace

Intelligent electrical workshop

1000 ton crane test bed

Profile laser cutting machine

3D vision bevel cutting robot

Wij waarderen uw feedback! Vul het onderstaande formulier in, zodat we onze services kunnen aanpassen aan uw specifieke behoeften.

Klik op de knop om productinformatie en offertes op WhatsApp te krijgen.

Krijg citaat

Laatste opmerkingen