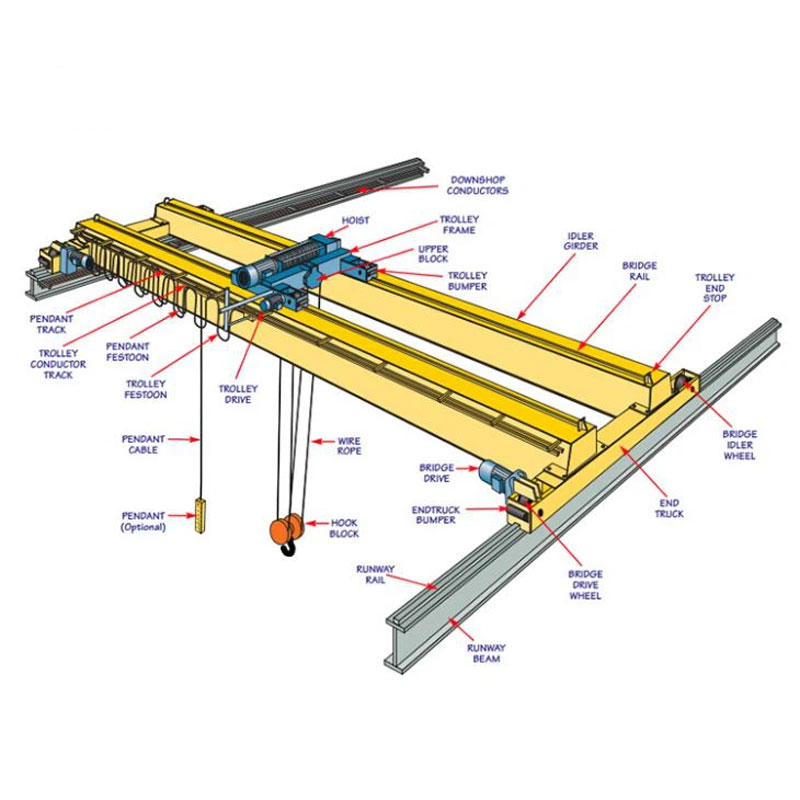

The 30 Ton Overhead Crane adalah peralatan pengendalian bahan teras yang direka untuk aplikasi perindustrian sederhana hingga berat.

The 30 Ton Overhead Crane adalah peralatan pengendalian bahan teras yang direka untuk aplikasi perindustrian sederhana hingga berat. Ia cemerlang dalam mengangkat, bergerak, dan meletakkan beban sehingga 30 tan dengan ketepatan tinggi, kestabilan, dan keselamatan, menjadikannya aset yang sangat diperlukan untuk industri yang memerlukan pengangkutan beban berat yang cekap. Sama ada dalam bengkel pembuatan, loji kuasa, atau meter logistik, kren ini mengoptimumkan aliran kerja, mengurangkan intensiti buruh manual, dan memastikan kecekapan operasi yang konsisten.

The 30 Ton Overhead Crane Mengintegrasikan Kejuruteraan Lanjutan, Reka bentuk keselamatan, dan fungsi mesra pengguna, dengan kelebihan utama berikut:

|

Kategori parameter

|

Butiran spesifikasi

|

|

Kapasiti mengangkat dinilai

|

30 tan (cangkuk utama); 5-10 tan (cangkuk tambahan, pilihan)

|

|

Julat rentang

|

10 m - 31.5 m (disesuaikan untuk bengkel khas)

|

|

Mengangkat ketinggian

|

6 m - 30 m (disesuaikan berdasarkan ketinggian bengkel)

|

|

Mengangkat kelajuan (Cangkuk utama)

|

0.8 - 8 m/my (kekerapan berubah -ubah, Peraturan Stepless)

|

|

Mengangkat kelajuan (Cangkuk aux)

|

2 - 16 m/my (jika dilengkapi)

|

|

Kelajuan perjalanan membujur (Kren)

|

20 - 40 m/my (kekerapan berubah -ubah)

|

|

Kelajuan perjalanan melintang (Troli)

|

10 - 20 m/my (kekerapan berubah -ubah)

|

|

Kelas pekerja

|

A5 - A7 (A5: tugas sederhana, 1,000 jam kerja/tahun; A7: tugas berat, 4,000 jam kerja/tahun)

|

|

Bekalan kuasa

|

380V/50Hz/3PH (disesuaikan untuk 415V/60Hz untuk pasaran antarabangsa)

|

|

Berat keseluruhan

|

15 - 35 tan (berbeza mengikut ketinggian rentang dan mengangkat)

|

|

Kuasa motor (Angkat)

|

18.5 - 37 kw (cangkuk utama); 5.5 - 11 kw (cangkuk tambahan, pilihan)

|

|

Kuasa motor (Perjalanan membujur)

|

2× 7.5 - 2 × 15 kW (satu motor setiap rasuk akhir)

|

|

Kuasa motor (Perjalanan melintang)

|

1× 3 - 1 × 7.5 kW

|

The 30 kren overhead tan digunakan secara meluas dalam industri yang memerlukan pengendalian beban berat, Terima kasih kepada kebolehsuaiannya kepada persekitaran kerja yang berbeza:

Walaupun kedua -dua model mengendalikan 30 tan, Reka bentuk struktur dan senario aplikasi mereka berbeza dengan ketara. Jadual berikut membandingkan aspek utama:

|

Dimensi perbandingan

|

Girder tunggal 30 Ton Crane Overhead

|

Double-Girder 30 Ton Crane Overhead

|

|

Reka bentuk struktur

|

Rasuk utama tunggal (Rasuk i-balok atau kotak) disokong oleh rasuk akhir.

|

Dua rasuk utama selari (Rasuk kotak) disambungkan oleh silang silang.

|

|

Kesesuaian span

|

Maksimum maksimum ≤ 22 m (terhad oleh kapasiti galas beban satu rasuk).

|

Rentang maksimum ≥ 31.5 m (Sesuai untuk bengkel/meter besar).

|

|

Mengangkat ketinggian

|

Secara amnya 6 - 18 m (terhad oleh ruang pemasangan troli).

|

Secara amnya 10 - 30 m (lebih banyak ruang menegak untuk pergerakan troli).

|

|

Penghunian ruang

|

Bilik kepala bawah (menjimatkan ketinggian bengkel); saiz keseluruhan yang lebih kecil.

|

Ruang kepala yang lebih tinggi (memerlukan bengkel yang lebih tinggi); Jejak yang lebih besar.

|

|

Kestabilan operasi

|

Kestabilan sederhana (terdedah kepada pesongan rasuk sedikit di bawah beban berat).

|

Kestabilan yang tinggi (rasuk dwi mengedarkan beban secara merata, pesongan minimum).

|

|

Kekerapan beban

|

Sesuai untuk operasi frekuensi sederhana (≤ 1,500 kitaran/tahun).

|

Sesuai untuk operasi frekuensi tinggi (≥ 3,000 kitaran/tahun).

|

|

Kos

|

Kos awal yang lebih rendah (30% - 50% lebih murah daripada girder double).

|

Kos awal yang lebih tinggi (Tetapi kos penyelenggaraan jangka panjang yang lebih rendah untuk kegunaan berat).

|

|

Konfigurasi pilihan

|

Terhad (cangkuk tambahan, kawalan jauh sahaja).

|

Serba boleh (cangkuk tambahan, Dapatkan baldi, magnet, Sistem anti-sway, dll.).

|

|

Senario yang ideal

|

Bengkel kecil ke sederhana, Pengendalian beban berat frekuensi rendah (Mis., kilang jentera kecil).

|

Bengkel besar, Pengendalian beban berat frekuensi tinggi (Mis., Kilang keluli, loji kuasa).

|

Q1: Faktor apa yang harus saya pertimbangkan semasa memilih a 30 Ton Crane Overhead?

A1: Faktor utama termasuk:

S2: Berapa kerap a 30 kren overhead tan memerlukan penyelenggaraan?

A2: Penyelenggaraan mengikuti jadual tiga peringkat:

Q3: Boleh 30 kren overhead tan disesuaikan untuk keperluan khas?

A3: Ya. Penyesuaian umum termasuk:

Q4: Apa pensijilan keselamatan wajib 30 Ton kren overhead?

A4: Pensijilan berbeza mengikut wilayah, Tetapi yang utama termasuk:

S5: Apakah hayat perkhidmatan a 30 Ton Crane Overhead?

A5: Di bawah penggunaan biasa dan penyelenggaraan yang betul, Hayat perkhidmatan adalah 10 - 15 tahun. Faktor utama yang mempengaruhi kehidupan termasuk:

The 30 kren overhead tan menggabungkan kuasa, keselamatan, dan fleksibiliti untuk memenuhi pelbagai keperluan pengendalian bahan industri berat. Dengan reka bentuk yang disesuaikan dan prestasi yang boleh dipercayai, Ini adalah pelaburan jangka panjang untuk meningkatkan kecekapan operasi dan memastikan keselamatan tempat kerja. Untuk maklumat lanjut mengenai model, petikan, atau penyelesaian tersuai, Sila hubungi pasukan teknikal kami.

Kami menghargai maklum balas anda! Sila lengkapkan borang di bawah supaya kami dapat menyesuaikan perkhidmatan kami dengan keperluan khusus anda.

Gambaran Keseluruhan Produk Kren overhed girder berkembar yang diperakui CE kami ialah persamaan mengangkat premium……

Ketahui lebih lanjut →

Roda kren palsu adalah komponen galas beban teras dalam pelbagai sistem kren perindustrian ……

Ketahui lebih lanjut →

Pengenalan Produk Crane Overhead Headhead Rendah adalah handlin bahan khusus ……

Ketahui lebih lanjut →

Klik butang untuk mendapatkan maklumat produk dan petikan di WhatsApp.

Dapatkan petikan

Komen terkini