Ketika datang ke operasi mengangkat berat, Cangkuk kren memainkan peranan penting dalam memastikan pengendalian bahan yang selamat dan cekap. Untuk mengangkat kapasiti seperti 20 tan, Reka bentuk dan dimensi cangkuk kren menjadi lebih penting. Dalam catatan blog ini, Kami akan meneroka 20 dimensi cangkuk kren tan, kepentingan mereka, Spesifikasi tipikal, dan bagaimana memilih cangkuk yang tepat untuk aplikasi anda.

A 20 Ton Crane Hook adalah komponen pengangkat gred perindustrian yang direka untuk menanggung beban sehingga 20 Ton metrik (20,000 kg). Ia biasanya digunakan dalam kren overhead, kren gantri, dan kren jib dalam industri tugas berat seperti loji keluli, Limbungan kapal, gudang, dan tapak pembinaan.

Dimensi cangkuk kren secara langsung memberi kesan:

Pengagihan beban

Keselamatan dan ketahanan

Keserasian dengan sentuhan, belenggu, dan beban

Pematuhan piawaian (Dari, Fem, ISO)

Dimensi yang tidak betul dapat menyebabkan prestasi buruk, Haus yang berlebihan, atau bahkan kemalangan.

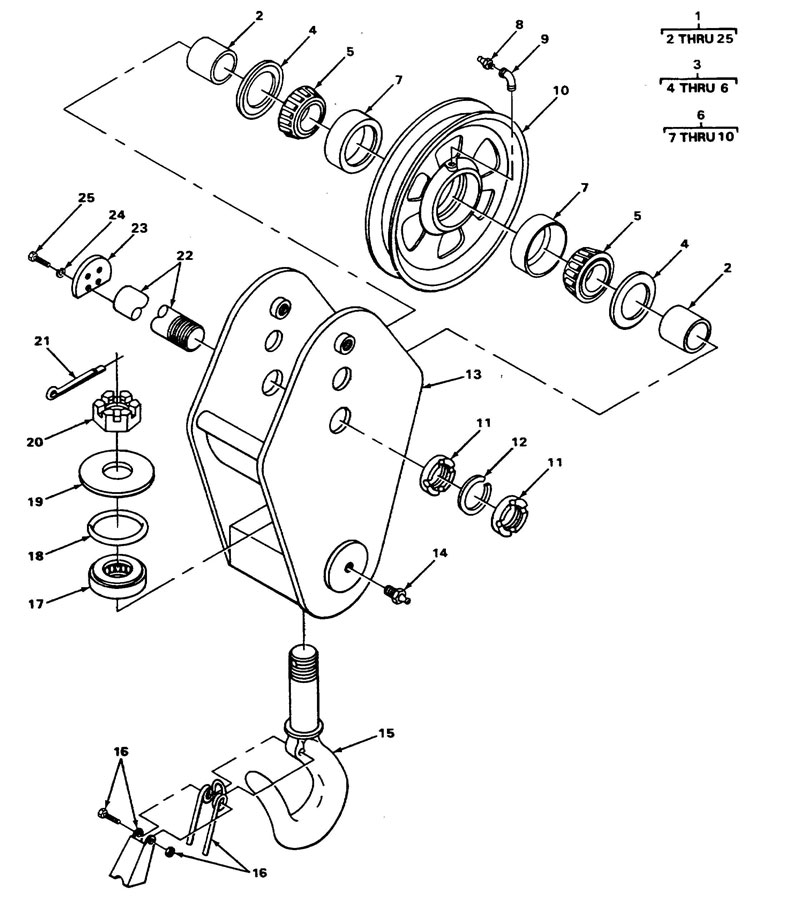

| Parameter | Cangkuk tunggal | Cangkuk ganda |

| Kapasiti dinilai | 20 Ton cangkuk kren | 20 ton |

| Bahan | Keluli aloi kekuatan tinggi | Keluli aloi kekuatan tinggi |

| Pembukaan cangkuk (B) | 85 - 100 mm | 75 - 90 mm |

| Ketinggian cangkuk (H) | 400 - 500 mm | 350 - 450 mm |

| Lebar cangkuk (W) | 200 - 250 mm | 180 - 230 mm |

| Diameter aci (D) | 75 - 90 mm | 70 - 85 mm |

| Kedalaman tekak | 60 - 80 mm | 60 - 75 mm |

| Berat | ~ 55 - 70 kg | ~ 60 - 80 kg |

Nota: Dimensi sebenar mungkin berbeza -beza bergantung pada jenis cangkuk (menempuh atau berlapis), pengilang, dan piawaian yang digunakan.

1. Cangkuk kren palsu

Dihasilkan dari sekeping keluli kekuatan tinggi

Biasa secara umum aplikasi mengangkat overhead

2. Cangkuk kren berlamina

Dibina dengan menyusun plat keluli

Sesuai untuk persekitaran yang melampau atau apabila laluan beban sandaran diperlukan

3. Cangkuk tunggal vs. Cangkuk ganda

Cangkuk tunggal: Struktur mudah, digunakan dalam mengangkat satu arah

Cangkuk dua kren: Mengangkat simetri, mengurangkan tekanan beban sisi

Semasa memilih a 20 Ton cangkuk kren, pertimbangkan:

1. Persekitaran permohonan (suhu, kelembapan, kakisan)

2. Ciri -ciri beban (beban statik atau dinamik)

3. Kekerapan operasi

4. Pematuhan dengan OSHA, ISO, atau standard din

5. Keserasian dengan peralatan angkat

1. Lakukan pemeriksaan dan penyelenggaraan secara berkala

2. Ganti cangkuk yang menunjukkan tanda -tanda ubah bentuk, Pakai, atau retak

3. Pastikan selak cangkuk selalu ada

4. Gunakan cangkuk dalam kapasiti yang dinilai

Memahami 20 Dimensi cangkuk kren ton adalah penting untuk operasi mengangkat yang selamat dan cekap. Dengan memilih saiz dan jenis cangkuk yang betul berdasarkan keperluan perindustrian anda, anda memastikan panjang umur peralatan mengangkat anda dan keselamatan operasi anda. Sentiasa berunding dengan pengilang atau pembekal yang bereputasi untuk mengesahkan spesifikasi dan pematuhan piawaian yang tepat.

Kami menghargai maklum balas anda! Sila lengkapkan borang di bawah supaya kami dapat menyesuaikan perkhidmatan kami dengan keperluan khusus anda.

Klik butang untuk mendapatkan maklumat produk dan petikan di WhatsApp.

Dapatkan petikan

Komen terkini