A single girder overhead crane is a versatile material handling equipment designed for lifting and moving loads in industrial settings.

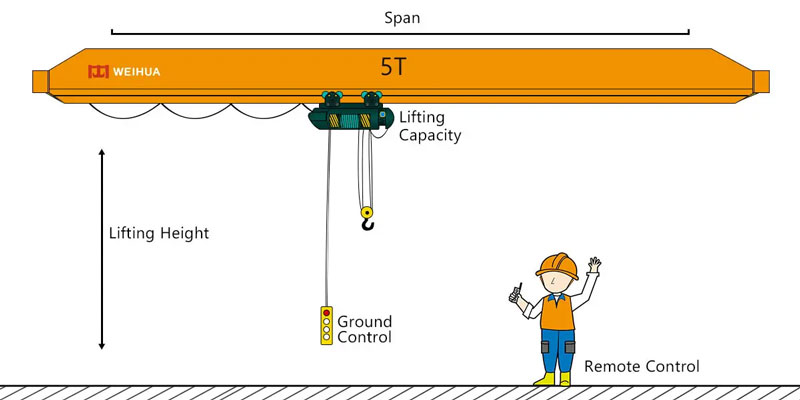

A single girder overhead crane is a versatile material handling equipment designed for lifting and moving loads in industrial settings. Composed of a single main beam (도리) supported by end carriages, a trolley, and a hoist, this crane operates on elevated runways, maximizing floor space utilization. Ideal for light to medium-duty applications, it balances cost-effectiveness, compact design, and reliable performance—making it a go-to choice for factories, 창고, and workshops seeking efficient load management.

Our single girder overhead cranes are engineered to meet rigorous industrial demands, with features that set them apart:

|

매개 변수

|

범위/세부사항

|

|

리프팅 용량

|

0.5 - 32 톤 (customizable for higher capacities upon request)

|

|

스팬 길이

|

5 - 30 미터 (adjustable based on facility dimensions)

|

|

리프팅 높이

|

3 - 30 미터 (extendable with specialized configurations)

|

|

노동 계급

|

A3 – A5 (suitable for medium-duty, intermittent operations)

|

|

호이스트 속도

|

0.8 - 16 m/나 (가변 속도 옵션 사용 가능)

|

|

트롤리 이동 속도

|

10 - 30 m/나

|

|

크레인 이동 속도

|

20 - 45 m/나

|

|

전원 공급 장치

|

380V/3PH/50Hz (customizable for 220V, 440다섯, or other regional standards)

|

|

제어 시스템

|

펜던트 제어, 원격 제어 (wireless optional), or PLC integration

|

Our single girder overhead cranes excel in diverse sectors, streamlining material handling across:

Q1: What’s the difference between a single girder and 이중 대들보 오버헤드 크레인?

A1: Single girder cranes use one main beam, 더 가볍다, more affordable, and ideal for light to medium loads. Double girder overhead cranes have two beams, offering higher lifting capacities (32+ 톤) and greater stability for heavy-duty applications.

Q2: Can a single girder overhead crane be installed outdoors?

A2: Yes—we offer weatherproof models with corrosion-resistant coatings, sealed electrical components, and rain shields, suitable for outdoor yards or construction sites.

Q3: 설치하는데 시간이 얼마나 걸리나요??

A3: Installation typically takes 3–7 days, depending on the crane size, site preparation (예를 들어, runway setup), and configuration complexity. Our team provides on-site support for seamless setup.

Q4: What maintenance is required?

A4: Regular maintenance includes checking hoist cables for wear, lubricating trolley/overhead crane wheels, testing safety switches, and inspecting electrical connections. We recommend quarterly inspections for optimal performance.

Q5: Are your cranes compliant with international standards?

A5: 전적으로. All our single girder overhead cranes meet ISO 9001 quality standards, CE certification for EU markets, and OSHA guidelines for safety, ensuring global compatibility.

PDF로 공유: 다운로드

우리는 귀하의 의견을 소중히 여깁니다! 귀하의 특정 요구에 맞게 서비스를 조정할 수 있도록 아래 양식을 작성하십시오..

최신 의견